How do you calculate upper control limit?

How do you calculate control limits? First calculate the Center Line. The Center Line equals either the average or median of your data. Second calculate sigma. The formula for sigma varies depending on the type of data you have. Third, calculate the sigma lines. These are simply ± 1 sigma, ± 2 sigma and ± 3 sigma from the center line.

How to calculate upper control limit?

What formulas are used to calculate control limits in Excel?

- Centerline. The centerline for a control chart serves as the basis for the chart's control limits. ...

- Sigma lines. Sigma lines are specific amounts of variable data within your set. ...

- Upper control limit. You calculate the upper control limit in a control chart from the centerline and Sigma lines for the data.

- Lower control limit. ...

What is the formula for upper control limit?

Where the parts of the formula are:

- µ represent the average

- Σ represents the sum

- n represents the total number of values

What is upper and lower control limits?

Out-of-control signals

- A single point outside the control limits. ...

- Two out of three successive points are on the same side of the centerline and farther than 2 σ from it. ...

- Four out of five successive points are on the same side of the centerline and farther than 1 σ from it. ...

- A run of eight in a row are on the same side of the centerline. ...

What are the upper and lower control limits on a control chart?

In a typical individual/moving range statistical process control chart, the upper and lower control limits (UCL and LCL) are three standard deviations from the historical mean of the set of readings. If the measurement remains within the upper and lower control limits, then the process is in control.

What is UCL and LCL in control chart?

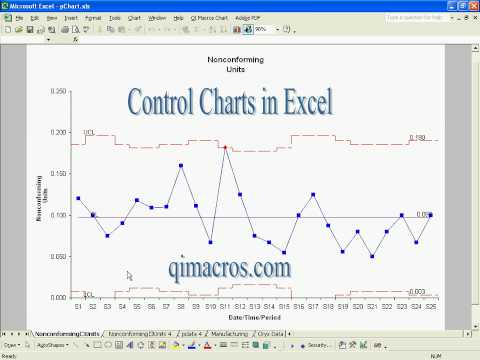

UCL represents upper control limit on a control chart, and LCL represents lower control limit. A control chart is a line graph that displays a continuous picture of what is happening in production process with respect to time. As such, it is an important tool for statistical process control or quality control.Apr 25, 2017

What is lower control limit in control chart?

On a control chart, the lower control limit is a line below the centerline that indicates the number below which any individual data point would be considered out of statistical control due to special cause variation.

What is UCL in control chart?

Two other horizontal lines, called the upper control limit (UCL) and the lower control limit (LCL), are also shown on the chart. These control limits are chosen so that almost all of the data points will fall within these limits as long as the process remains in-control.

How is UCL calculated?

How to calculate upper control limit (UCL)? Upper control limit formulaThe upper control limit formula: UCL = x - (-L * σ)The lower control limit formula: LCL = x - (L * σ)Nov 29, 2021

What is UCL and LCL Six Sigma?

The upper control limit, or UCL is typically set at three standard deviations, or sigma, above the process mean, and the lower control limit, LCL, would be set three sigma below the mean.Sep 26, 2017

What are the 4 types of control charts?

Types of Control ChartsX-Chart. X-Charts present variable data. ... P-Chart. P-Charts are used for data that is counted. ... NP-Chart. NP-Charts are used to present the number of nonconforming or conforming items. ... C-Chart. ... U-Chart. ... MR-Chart. ... Individual MR-Chart. ... Custom Data Control Chart.

How do you read UCL and LCL?

The UCL is the largest value you would expect from a process with just common causes of variation present. The LCL is the smallest value you would expect with just common cause of variation present.

How Are Control Limits calculated?

The simple answer: the average of your data ± sigma. The hard answer: The formula for sigma depends on the type of data you have. Is it continuous...

You Can Try and Calculate Control Limits Yourself, but ...

1. It will suck up a bunch of your time. 2. You'll probably make mistakes and aggravate customers. 3. And you will find your homegrown template har...

How Many Data Points Are Used to Calculate Control Chart Limits?

Generally, you calculate control limits using your first 20 to 25 data points and then you use those limits to evaluate the rest of your data. If y...

Qi Macros Makes It Easy to Update Control Limit Calculations

Once you create a control chart using QI Macros, you can easily update the control limits using the QI Macros Chart Tools menu. To access the menu,...

What is a control chart in Six Sigma?

A control chart in Six Sigma is the main statistical control process (SPC), which involves using statistical methods to monitor a process. It allows quality control (QC) professionals to track the input or output of a specific process over time to identify and resolve extreme variations before they become significant concerns.

What formulas are used to calculate control limits in Excel?

You can add specific formulas into the cells on your control chart to calculate upper control limits and lower control limits in Excel. Each serves an important purpose, so understanding their role and how to use them is beneficial for creating an effective control chart.

Example of a control chart in Excel

Here's an example of a complete control chart based on the data stored in column B:

Tips for creating a chart in Excel

If you already know what your control limits are, you can skip the steps needed to calculate them and simply input them into the cells below the data you want to show in the chart. Remember that you may need your upper control limit, your lower control limit and your centerline before you can create the chart that shows all that data.

What is a control limit chart?

What are Control Chart Limits? Control limits distinguish control charts from a simple line graph or run chart. They are like guard rails that help you determine if your process is stable or not. Control limits are calculated from your data.

How many types of control charts are there?

There are seven main types of control charts (c, p, u, np, individual moving range XmR, XbarR and XbarS.) Plus there are many more variations for special circumstances. As you might guess, this can get ugly. Here are some examples of control limit formulas:

What is the control limit on a control chart?

The control limits of your control chart represent your process variation and help indicate when your process is out of control. Control limits are the horizontal lines above and below the center line that are used to judge whether a process is out of control.

What is control limit?

Control limits are based on process variation. Specification limits are based on customer requirements. A process can be in control and yet not be capable of meeting specifications.

How to calculate control limits?

1. Use the standard control limit formula and the control chart table to calculate the control limits. Control limit formula will vary depending on the statistic (average, range, proportion, count) being plotted. Ensure you are using the right formula! 2. Use the control limits to assess if there is a special cause.

What is control limit?

Control limits are one part of a control chart that allows you to identify common and special cause variation. If you understand how control limits were designed to work, then you have the key to effective process improvement.

What does it mean when a point is outside the control limit?

The points outside the control limit indicate special causes where the calls are shorter than would be expected. This is a positive type of special cause, because the manager would like the calls to be shorter, if possible.

What is the purpose of control limits?

Control limits are used to mark the point beyond which a sample value is considered a special cause of variation. They are also used to define the upper and lower limit of the common cause variation.

Why are control limits not a requirement?

Control limits are not a requirement, like specification limits. Because control limits are based on the process measure, they give you a realistic guideline as to what to expect from the process. 2.

Can control limits be associated with any exact probability of looking for trouble?

Control limits can thus not be associated with any exact probability of looking for trouble (an assignable cause) when there is none, nor with failure to look for trouble when an assignable cause does not exist. It was for such reasons that he used 3-sigma limits. Experience of 50 years shows how right he was.”.

Can you use the control limit formula in a control chart?

No. Most every time, it is best to use the control limit formula and the control chart factor table to calculate the control limits. If, in a rare case, you have a specialty control chart that needs to use probability limits instead of regular control limits, contact a control chart expert for assistance.

How to use control chart?

When to Use a Control Chart 1 When controlling ongoing processes by finding and correcting problems as they occur 2 When predicting the expected range of outcomes from a process 3 When determining whether a process is stable (in statistical control) 4 When analyzing patterns of process variation from special causes (non-routine events) or common causes (built into the process) 5 When determining whether your quality improvement project should aim to prevent specific problems or to make fundamental changes to the process

What is a control chart in healthcare?

Using Control Charts In A Healthcare Setting (PDF) This teaching case study features characters, hospitals, and healthcare data that are all fictional. Upon use of the case study in classrooms or organizations, readers should be able to create a control chart and interpret its results, and identify situations that would be appropriate for control chart analysis.

What is the central line on a control chart?

A control chart always has a central line for the average, an upper line for the upper control limit, and a lower line for the lower control limit. These lines are determined from historical data. By comparing current data to these lines, you can draw conclusions about whether the process variation is consistent (in control) or is unpredictable ...

Bias Correction Control Chart Constants

Bias correction constants are the fundamental quantities that allow you to calculate other higher level control constants such as A2, D3, D4, etc. Subsequent sections provide examples of how these constants are calculated.

XmR Control Chart Constants

XmR charts are the easiest control charts to make. For a full explanation see the following articles:

Summary

Tables of control chart constants and a brief explanation of how control chart constants are used in different contexts has been presented. XmR, XbarR, XbarS, mR, R, and S type control charts all require these constants to determine control limits appropriately.