How to determine load center distance for forklifts?

- Load Center Distance: 600mm

- Mast Vertical 2000kg

- Forward tilt 1000kg

- Height A: 5000mm.

- Therefore, from this information, the maximum weight the forklift can carry is 2000kg to a height of 5000mm, as long as the mast is vertical, or back tilt is applied.The ...

What is the load centre of a forklift?

It depends on what kind of forklift you have. A load center of 535 mm is within the standard 600 mm load center distance for most counterbalance forklifts; however, for a 2450-kg load, a forklift with a 3500 kg - 4000 kg lifting capacity would be most recommended.

What is the center of gravity on a forklift?

What is the center of gravity on a forklift? When at rest, on level ground, the forklift’s center of gravity is within the stability triangle. But if the forklift is put in motion, or sits on a sloping surface, it’s center of gravity shifts.

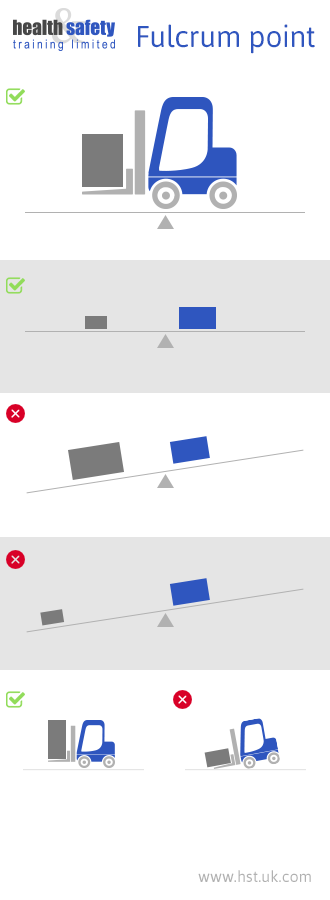

What is the fulcrum point?

The fulcrum point refers to a major change in the direction of a security or the economy in general. The tipping point is a key tipping point and can represent an opportunity for investors who can identify it and act accordingly.

Where is the point of balance on a forklift?

fulcrumThe point of balance on a forklift is called the fulcrum. The fulcrum is where a vertical line drawn through the centre of the front axle would meet the ground. An easy way to remember this is the fulcrum is where the front wheels touch the ground.

Where is the fulcrum on a lift truck?

The forward wheels are the fulcrum. This is the same principle used for a teeter-totter. In order for this principle to work for a lift truck, the load of the forks must be balanced by the weight of the lift truck.

What is the balance point of a counterbalance lift truck?

Most counterbalanced forklifts have a three-point suspension system, meaning that the truck is supported at the two front wheels and the center of the steer axle. If you imagine all three points connected into a triangle, this is the forklift's stability triangle.13-Jun-2018

What is the ideal location of the loads center of gravity when it is on the forks?

The load center is the distance from the face of the forks to the load's center of gravity. Many forklifts are rated using a 24-inch load center, which means that the load's center of gravity must be 24 inches or less from the face of the forks.

What makes a forklift counterbalanced?

The counterbalance forklift features two forks at the front and has the ability to drive up close to a load to pick it up and move it. The name comes from the counterweight in the rear of the vehicle. This is to compensate for the heavy load being lifted at the front.13-Jun-2018

What is inching on a forklift?

The purpose of the inching pedal is to disengage the transmission without having to shift the gear lever into neutral every time a lift is performed. This pedal allows you to bring the forklift to a stop or to slow it down. ... This pedal allows you to adjust the rotational speed of the engine.

What is the effect on forklift by placing the fulcrum closer to the load?

If the fulcrum is closer to the load, then less effort is needed to move the load a shorter distance. If the fulcrum is closer to the effort, then more effort is needed to move the load a greater distance.09-Mar-2020

What three points make up a forklift stability triangle?

There's the weight of the load itself and the counterbalance weight located in the engine. This weight is distributed on three points—the front two wheels and the pivot point on the back axel—forming an imaginary “triangle.” This is the stability triangle of the forklift.04-Nov-2020

What are the supporting points of the stability triangle on a lift truck?

Lift trucks are built on three-point suspension systems, the physics of which resemble a triangle. Support points lie at both ends of the front axle, with another located at the center of the rear axle. Together, this forms a “stability triangle” that operators must stay within when the truck is in motion.

Where must a forklift center of gravity remain in order for the forklift to stay upright?

In order for the lift truck to be stable (not tip-over forward or to the side), the Center of Gravity must stay within the area of the lift truck stability base—a triangle drawn between the front wheels and the pivot of the rear axle. This is sometimes referred to as the “stability triangle”.

What area on a forklift is formed by its points of suspension and contains its center of gravity?

Forklift suspension systems are built around three points: the two front drive wheels, and the turning center (pivot pin) of the back wheels. The forklift's own center of gravity sits within this triangle—also known as the stability triangle.16-Jan-2021

Where is the load center on a forklift?

A load center is the horizontal distance from the vertical face of the forks to the center of gravity of the load. As a general rule, load center is 24" from the face of the forks (the center point of standard 48” x 48” pallet). Forklift capacities range from about 3,000 lbs up to more than 70,000+ lbs.21-Nov-2017

What is the pivot point of a forklift?

The fulcrum, or pivot point, is the dividing line between the machine's weight and the load's weight. Forklift America reports most forklifts indicate their load capacity on their respective data plates. The most important thing to remember when evaluating a load is that every object that is lifted has a center of gravity just as ...

Why does a forklift tip forward?

It is this positioning of the load that keeps the loaded forklift stable. Placing the load too far away from the front axle is likely to cause the forklift to tip forward, while placing it too far to either side is likely to cause it to tip sideways. ADVERTISEMENT.

What is a cantilever forklift?

The cantilever system is similar to a simple teeter-totter, a device that also relies on a fulcrum to operate. According to the Occupational Safety & Health Administration, a balanced forklift is highly stable and capable of carrying significant weight.

What is the most important thing to remember when evaluating a load?

The most important thing to remember when evaluating a load is that every object that is lifted has a center of gravity just as the forklift and load together have a center of gravity. This is why it is crucial for a forklift driver to keep the load within the triangular area between the front wheels, or fulcrum, and rear steering axle.

What is The Fulcrum Point On A Forklift

It is the load center and load side that determines the load capacity of a forklift. A load center is a distance from the face of the forks to the load center of gravity. A load side is a distance from one edge of an object to another.

Forklift Fulcrum Point

The central pivot point for a forklift is called the fulcrum. Fulcrums can be used to create force without causing any position changes. They are often found in machinery because they allow minimal effort at one end (the fulcrum or pivot point). The front axle is the fulcrum of the forklift where the counterweight and the load find balance.

How Forklifts Work – Fulcrum & Counterbalances

Counterbalanced forklifts rely on their load center to operate correctly. The center is the fulcrum point as it is where the load and load sides meet.

Understanding Forklift Load Center Using the Forklift Data Plate

When load capacity is being calculated for a forklift, the load center is the fulcrum point. To understand forklifts’ load and lift capacity, it is essential to read the load center from a data plate.

Knowing The Forklift Stability Triangle

A stability triangle helps determine what load capacity is safe for forklift operation during certain times of the year. The stability triangle is part of FEMA’s best practices guide for operating a forklift in cold weather so that you don’t exceed your load capacity and cause harm or injury to yourself or others.

What is the fulcrum of a forklift?

The fulcrum is the central pivot point of a seesaw. The front axle is the fulcrum of the forklift where the counterweight and the load find balance. The only major difference between a forklift and a seesaw, is that the forklift counterweight should always provide more force than the load so the forklift does not tip forward.

What is the center of a forklift?

A forklift has a fulcrum and two resistances, the counterweight on the back of the forklift and the load on the forks. The middle of the load is considered the load center when the load is evenly distributed across the pallet. According to OSHA, “The load center is the distance from the face of the forks to the load’s center of gravity.”.

What is the most common load center?

The most common load is a 48-inch by 48-inch pallet. The center of that pallet is 24-inches, which is the pallet’s load center assuming the load is equally distributed across the pallet. 24-inches is the most common load center, but 36-inch and 48-inch forklift load centers are also fairly common.

What is a data plate for a forklift?

Manufacturers provide a data plate for every new forklift. The data plate contains important information about the forklift, such as load capacity at a specified load center, fuel type, weight, lift height, among other data points. Ignoring load center guidelines or installing an attachment without notifying the manufacturer can put you, your operators, and your business at risk of damage to the forklift, accidents, and injuries. Be sure to notify the manufacturer and request a new data plate to adjust the metrics to the changes made to the forklift.

Is a counterbalanced forklift considered a load center?

Counterbalanced Forklifts and The Forklift Load Center: A Consideration of Gravity. Forklifts must be powerful and tough to endure the tough settings they operate in. However, as powerful and as tough as they might be, they are by no means exceptions to the laws of gravity.