Bobweight When a crankshaft is balanced, the actual rods and pistons

Detroit Pistons

The Detroit Pistons are an American professional basketball team based in Detroit, Michigan. The Pistons compete in the National Basketball Association as a member of the league's Eastern Conference Central Division and plays its home games at Little Caesars Arena. The team was fo…

How do you put bobweights on a crankshaft?

Use a level to ensure the bobweight is on the crank properly. It’s a little bit more art than science here. “Each bobweight goes on the crankshaft 90-degrees from each other. Once you have your bobweights placed on the crank, the machine needs to know how far away the bearing is from the other bearing and what the tolerance is.

What is the counterbalance weight of a crankshaft?

For internally balanced crankshafts, the counterbalance weight is usually equal to 100% of the rotating weight + 50% of the reciprocating weight. However, while the 50% factor has been proven over time, it is not cast in stone and some experts disagree on the exact value.

How much does a crankshaft bearing weigh?

The next thing your balancer will want to know is your bearing insert weight. Steve’s bearing’s – the upper and lower crankshaft bearings – weighed 40.9 grams. Next, you’ll need to enter how many rods per throw are on your crankshaft.

What is a bobweight on a car?

“The bobweight consists of what is connected to the crankshaft – what is spinning around (on the crank journal) and what is going up and down in the cylinder (rods and pistons). Anything rotating around is called rotating weight, and anything going up and down is called reciprocating weight.

What is a Bobweight?

bobweight (plural bobweights) A counterweight on part of a machine. A weight fixed to the trim tab of an aircraft that brings the nose down at low speeds (to avoid stalling)

Why is crankshaft balancing necessary?

It is necessary for any engine's crankshaft to be in balance to operate without damage. All crankshafts are balanced at the factory, but not to the same degree as would be required for racing, or even by a careful owner. The factory balance is only production-line quality, and can be improved upon by diligent effort.

What happens if the crankshaft is not balanced?

Without counterweights, a crankshaft would be unbalanced and cause a lot of wear and tear on the engine. In addition, an unbalanced crankshaft can lead to decreased performance and shorter engine life.

How much is it to balance a crankshaft?

around $200As for the cost, most balance jobs price in at around $200 and typically take up to two hours to complete—of course, this is assuming everything checks out clean. If weight has to be added for a perfect balance, you can expect the price and the amount of time it takes to get the job done to go up accordingly.

How do you calculate Bobweight?

An 1,800-gram bob weight is basically the amount of weight in each of the counterweights. However, you don't just add all the values up to determine bob weight. The formula is 100 percent of the rotating weight plus 50 percent of the reciprocating weight.

How crankshaft balancing is done?

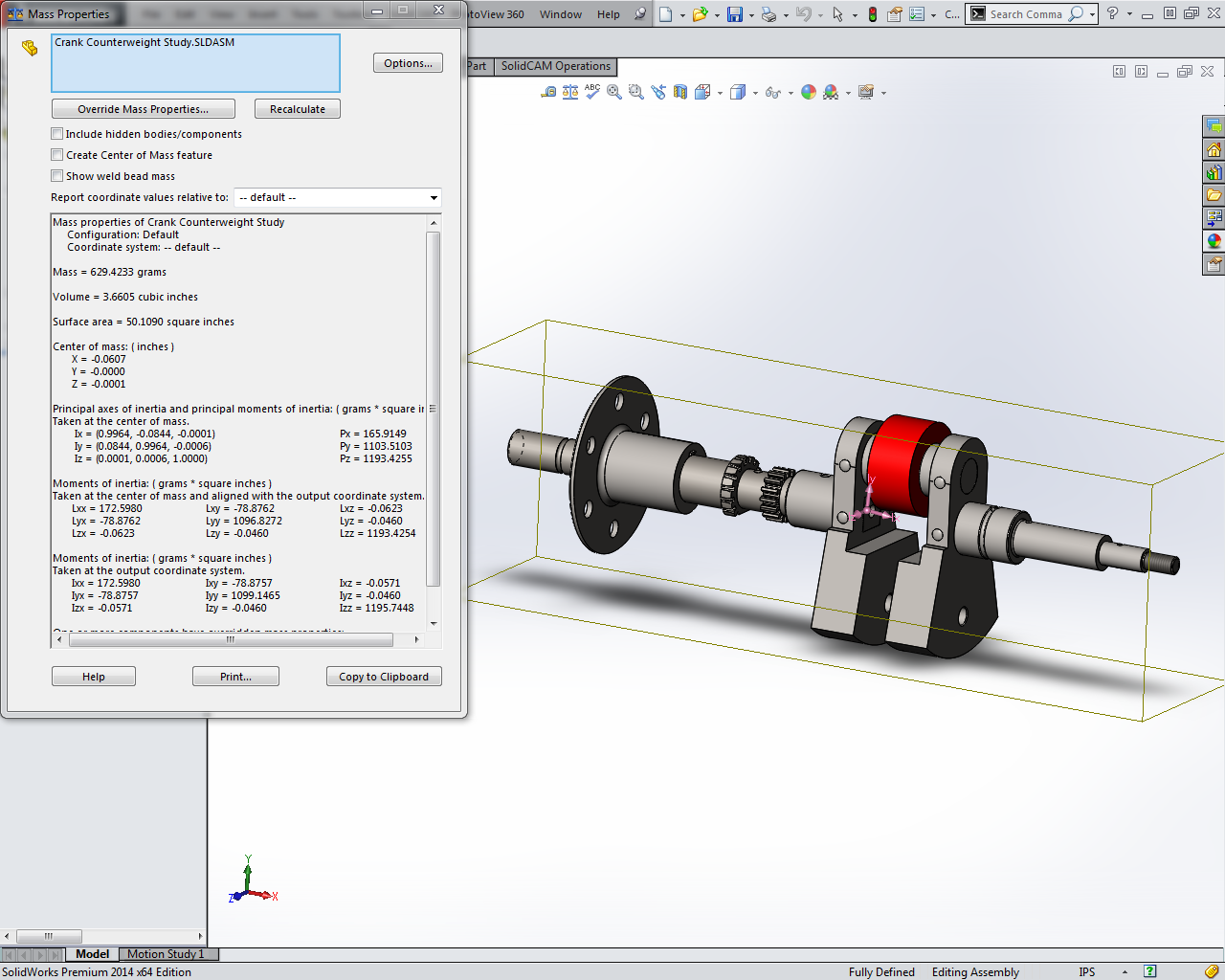

During the balancing process, bobweights are bolted to each rod journal to simulate the mass of a pair of pistons and rods. This is because each rod journal supports two sets of pistons and rods. After bolting the bobweights to the crankshaft, the balancer spins the assembly to roughly 750 rpm.

How do you know if your crank is internally balanced?

An internally balanced engine has all the counterweight on the crank. External parts like the balancer and flexplate/flywheel have a neutral balance. They will not affect the other rotating parts.

How do you balance crank and pistons?

5:0315:45Engine Building Part 4 - Balancing Crank, Pistons & Rods - YouTubeYouTubeStart of suggested clipEnd of suggested clipSo unwrap all your pins and circlips insert them in the bottom the piston. Like so and then whenMoreSo unwrap all your pins and circlips insert them in the bottom the piston. Like so and then when away each piston individually.

Is balancing an engine necessary?

0:102:43Why Is Engine Balancing Important? [HPA Q&A] - YouTubeYouTubeStart of suggested clipEnd of suggested clipAcross the set to make sure that they're within their sin intolerance. So even if we aren't doingMoreAcross the set to make sure that they're within their sin intolerance. So even if we aren't doing any balancing work we're still going to be dealing with components that have some degree of balance.

Does balancing an engine increase horsepower?

One of those “tricks” is balancing the rotating assembly of an engine. While this won't increase horsepower, balancing adds longevity and reliability. Most critical components which rotate at high speed (such as tires and wheels) need balancing to keep vibrations down while providing proper rotation.

How do you balance an engine at home?

Balancing an engine the simplest way in the home shop. Take all the connected moving parts from the rod journal to the top of the piston, Connecting rod, it's bearing, wrist pin, piston rod, piston, and any other hardware connected to all of this that is moving and weigh it.

Is engine balancing necessary?

0:102:43Why Is Engine Balancing Important? [HPA Q&A] - YouTubeYouTubeStart of suggested clipEnd of suggested clipAcross the set to make sure that they're within their sin intolerance. So even if we aren't doingMoreAcross the set to make sure that they're within their sin intolerance. So even if we aren't doing any balancing work we're still going to be dealing with components that have some degree of balance.

Do I have to balance a new crankshaft?

So, no, you don't have to balance if everything is new and from reliable vendors. But when you're building a forced induction high performance engine - and even stock, our engines are high performance - it is a sensible thing to do.

How do you know if your crank is internally balanced?

An internally balanced engine has all the counterweight on the crank. External parts like the balancer and flexplate/flywheel have a neutral balance. They will not affect the other rotating parts.

What causes engine imbalance?

Causes of imbalance Pistons moving upwards/downwards. Connecting rods moving upwards/downwards. Connecting rods moving left/right as they rotate around the crankshaft, however the lateral vibrations caused by these movements are much smaller than the up–down vibrations caused by the pistons.

What happens if you use counterweights on crankshaft?

If the counterweights are the correct weight to offset the weight of the rods and pistons, the crankshaft is balanced. If the counterweights are too heavy, material must be removed by drilling or milling the counterweights. If the counterweights are too light, weight must be added to the counterweights.

What is counterweight in a crankshaft?

The counterweights are designed to offset the weight of the rod and pistons. You have the weight of the crankshaft and the pistons and rods. At any point in the assembly’s rotation, the sum of all of the forces are roughly equal to zero. If the counterweights are the correct weight to offset the weight of the rods and pistons, ...

What is a harmonic dampener?

This involves a harmonic dampener or flywheel that has a weight on it in the same position as the counterweight that effectively "adds" to the weight of the counterweight on the crankshaft. Since the harmonic dampener (front) or flywheel (rear) play a part in the balancing of the assembly, they must be installed on the crankshaft ...

What is internal balance on crankshaft?

When a crankshaft is listed as "internal balance" or "external balance" this is stating how this crank is intended to be balanced. It can be balanced otherwise, but it is much more difficult to do so.

Why is the rod weight seperated into "big end" and "small end"?

This is necessary because the small end has a reciprocationg (back and forth) motion and the "big end" has a rotating motion. This split weight is figured on a special scale fixture that supports one end of the rod while weighing the other end.

Does Eagle 4340 have a harmonic dampener?

All Eagle forged 4340 steel crankshafts are designed for internal balance. An internally balanced kit will not include a harmonic dampener or flywheel because they are not required for balancing – use whatever brand you like. Externally balanced kits will include a harmonic dampener and/or flexplate as needed.

Can you make a crankshaft balanced?

Since different rods and different pistons are different weights, it is impossible to make a crankshaft that is balanced “right out of the box” for any rod and piston combination. All crankshafts must be balanced to your specific rod and piston combination.

What can be pressed into a crankshaft counterweight?

With extremely long-stroke cranks that have shorter counterweights, or rotating assemblies with very heavy pistons and connecting rods, tungsten metal slugs can be pressed into the counterweights to increase mass. The mass of the crankshaft counterweights should equal 100 percent of the rotating mass and 50 percent of the reciprocating mass.

What should the counterweights of a crankshaft equal?

Machinists and engine builders have long been taught that, when balancing a crankshaft, its counterweights should equal the weight of the rotating mass, and equal half the weight of the reciprocating mass.

Why are bobweights bolted to rod journals?

During the balancing process, bobweights are bolted to each rod journal to simulate the mass of a pair of pistons and rods. This is because each rod journal supports two sets of pistons and rods. After bolting the bobweights to the crankshaft, the balancer spins the assembly to roughly 750 rpm.

Can a 90 degree crankshaft be balanced?

While this technique works extremely well for most street and race 90-degree V8 engines, the truth is it’s nearly impossible to balance a crankshaft perfectly. That’s because the balancer cannot account for variables like cylinder pressure, ring drag, rod length, counterweight phasing, engine rpm, stroke length, bearing friction, ...

Is crank balancing a real science?

In other words, the traditional method of balancing a crank is, at best, an imperfect science. In fact, it’s not based on any real science or mathematics at all. It’s simply a technique based on trial and error that happens to work well in most 90-degree, cross-plane V8s.

Who is Judson Massingill?

Author: Judson Massingill Judson Massingill is the co-founder and head instructor of the School of Automotive Machinists in Houston, TX. Along with his wife Linda, he runs one of the most highly respected vocational engine building schools in the country.

Rotating weight.....crankshaft....bobweight

How much performance could a person expect to gain from taking 9lbs out of the crank (54lbs down to 45lbs) and reducing the bobweight 60-70 grams?

crank weight

I really go after the light wt rotating crank assembly. I could see it to be worth .15 to .30 in ET on the drag strip. This would be very hard to get a real back to back test, but based on hundreds od engines I have done, this seems reasonable. JOE SHERMAN RACING

Re: crank weight

bigjoe1 wrote: I really go after the light wt rotating crank assembly. I could see it to be worth .15 to .30 in ET on the drag strip. This would be very hard to get a real back to back test, but based on hundreds od engines I have done, this seems reasonable. JOE SHERMAN RACING

bob wt

probably NOT. It is more important to reduce the weight of the rods and pistons than only the crank. Too bad. JOE SHERMAN RACING