A knuckle assembly in which the upper knuckle, steering arm and brake rails are formed as a one piece casting and the spindle and lower knuckle are formed as in integral forging.

Full Answer

What is the difference between a knuckle and spindle?

They are the same, just different terms. Technically, "knuckle" is more appropriate since the entire assembly that the ball joints bolt to is the knuckle. The "spindle" is the bar/axle that the hub rides on via bearings. With lowering or lifting knuckles, the spindle is located higher (lowering) or lower (lifting) on the knuckle.

What is the knuckle joint?

What Is a Knuckle Joint?

- A pore joint is a joint pin used to join two components that are loaded under tension. ...

- The single eye is inserted between double eyes so that all three holes are centered, and a pin is used to secure components.

- Pore joints are often used to connect rods that are subject to stress in structures such as roof tiles, bridges, and cranes. ...

What is the name of the knuckle joint?

The three joints are as follows:

- Carpometacarpal (CMC) Joint

- Metacarpophalangeal (MP) Joint

- Interphalangeal (IP) Joint

What is a knuckle car part?

Steering knuckle (Car Part Diagram) In automotive suspension, a steering knuckle is that part that contains the wheel hub or spindle and attaches to the suspension and steering components. It is variously called a steering knuckle, spindle, upright, or hub, as well. The wheel and tire assembly attach to the hub or spindle of the knuckle where ...

What is a knuckle assembly of a car?

A forged joint that usually includes the spindle and steering arm, allowing the wheel to pivot, is known as a Steering Knuckle. It is a forged component that holds the assembly of the suspension, steering, axle, brakes and wheel hub together.

What does a knuckle do on a car?

Purpose. The steering knuckle is the pivot point of the steering system, which allows the wheels to turn. On cars with conventional suspension systems, the steering knuckle's spindle locates and supports the inner and outer wheel bearings.

What is a knuckle on a truck?

The knuckle is where wheel meets suspension meets steering. In the case of front- or all-wheel-drive cars, this is also where power. enters the mix. The wheel mounts to the outside, via a hub or a spindle, and the tie rod and suspension connect inboard via mounts that allow the knuckle. to pivot (i.e., steer the car).

What's the difference between a knuckle and a spindle?

The knuckle is the part the spindle attaches to. The spindle carries the hub and bearing(s). Generally the spindle is used on non-driven wheels, but there are some where the spindle is hollow and the CV shaft extends through e.g. Some Nissan's.

How much does a knuckle replacement cost?

On MDsave, the cost of a Finger Joint Replacement with Arthroplasty ranges from $10,175 to $11,741. Those on high deductible health plans or without insurance can save when they buy their procedure upfront through MDsave.

How much does it cost to replace a steering knuckle?

The average cost for steering knuckle replacement is between $170 and $214. Labor costs are estimated between $169 and $213 while parts are priced at $1. This range does not include taxes and fees, and does not factor in your specific vehicle or unique location. Related repairs may also be needed.

When should I replace my suspension knuckles?

If the ball pin hole in the knuckle shows signs of excessive wear, corrosion or distortion, the knuckle should be replaced. Also check for signs of wear on the taper of the ball pin, which could also indicate a worn knuckle that needs replacement.

What happens if steering knuckle breaks?

Your wheel alignment will be thrown out of whack. This leads to uneven tire wear and poor handling. The damaged part can put additional stress on the ball joints.

Can you repair a steering knuckle?

Steering knuckles are heavy-cast parts made of steel or aluminum. They are not repairable and should be replaced if damaged. A damaged steering knuckle could be discovered anytime during the collision repair process. Many times a damaged knuckle escapes replacement up to the point of the vehicle getting an alignment.

What is the difference between knuckle and upright?

Re: What's the difference of the worlds "knuckle"and "uprigh The red part is the steering knuckle. It may also be referred to as spindle. The upright is the grey part (with slight blueish tint) connecting the lower and upper control arms (also called wishbones), in green.

What is steering knuckle bearing?

: a knuckle made to furnish a bearing for an automobile steering wheel, pivoted to the axle, and controlled in its swiveling motion by the steering gear.

How do you replace a steering knuckle?

5:2810:37How To Remove A Steering Knuckle or Spindle - YouTubeYouTubeStart of suggested clipEnd of suggested clipOkay and then the bottom is just flat 180 degrees again replace these you don't want to reuse. Them.MoreOkay and then the bottom is just flat 180 degrees again replace these you don't want to reuse. Them. There we go you'd be a little tricky sometimes but there we go okay.

What is Knuckle joint?

A knuckle joint is a mechanical joint used to connect two rods which are under a tensile load. When there is a requirement of a small amount of flexibility or angular movement is necessary. There is always an axial or linear line of action of load.

Failure of Knuckle Joint s

Failure of knuckle joints may cause accidents so it is necessary to design knuckle joints to withstand under tension without failure.

Design of Knuckle joint s

Selection of Material: As the joint is subjected to reversible stresses, then stresses induced will be repeated and the joint may fail due to fatigue. Hence the selection of material is carried out by considering low carbon steel which will withstand stresses developed in the above case and the cost of material will be within range.

Materials Used To Make Knuckle Joint

Knuckle joints are normally made of materials like aluminum, stainless steel, structural steel, magnesium, and cast iron. It has been found that knuckle joints made of aluminum have the highest safety factor of about 50 kN loading conditions.

Methods of Failure of Knuckle Joint

In learning the strength of the joint for different methods of failure, it is found that,

Applications of Knuckle Joint

By the way, Knuckle joints work in many places and they are also used in big industries. These are applied between the tie rod joint of a roof truss and the joint tension link in a bridge structure.

Disadvantages of Knuckle Joint

Knuckle joints give most of the benefits but they also have some drawbacks, which are as follows:

Conclusion

A knuckle joint is a mechanical joint employed to connect two rods under tensile loads when a small amount of flexion or angular moment is required. Now, I hope that you have learned about the “knuckle joint” and its different parts and working.

What are the components of a knuckle joint?

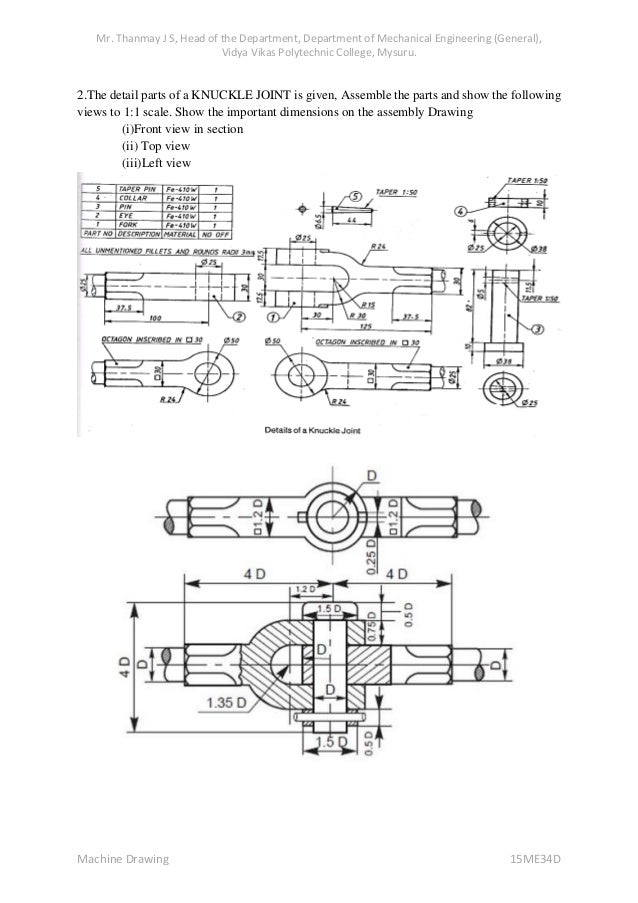

The knuckle joint assembly consists of the following major components: Single eye. Double eye or fork. Knuckle pin. At one end of the rod the a single eye is formed and a double eye is formed at the other end of the rod. Both, single and double eye are connected by a pin inserted through the eye.

How are double and single eyes connected?

Both, single and double eye are connected by a pin inserted through the eye. The pin has a head at one end and at other end there is a taper pin or split pin. For gripping purpose, the ends of the rod are of octagonal forms. Now, when the two eyes are pulled apart, the pin holds them together.

How to use knuckle joint?

Applications of Knuckle joint 1 To connect the trolley to the tractor. 2 To connect tie rod of jib crane. 3 Tension link in bridge structure 4 Link of roller chain 5 To connect the tie rod of a roof truss. 6 To connect robotic arms.

Where is the collar on a knuckle pin?

A collar is placed at the end of the knuckle pin such that the hole in the collar coincides with the hole in the knuckle pin. A tapered pin is passed through the holes to secure the collar & knuckle pin and prevents it from sliding off. This is how the knuckle joint is formed.

What is the difference between a knuckle joint and a cotter joint?

The main difference between a cotter joint and knuckle joint is that, a cotter joint can take compressive as well as tensile loads, whereas, a knuckle joint can withstand tensile load only. Also, a cotter joint does not permit angular movement between rods while a knuckle joint permits limited angular movement between the rods.

Is a knuckle joint flexible?

Limitations of Knuckle joint. The knuckle joint cannot hold up against large compressive load. It is not as flexible as a Universal joint. The angular movement is permitted in only one plane.

Construction of Knuckle Joint

In the knuckle joint (the two views of which are shown in Fig.), one end of one of the rods is made into an eye and the end of the other rod is formed into a fork with an eye in each of the fork legs.

Empirical relations are required to design a Knuckle joint

The dimensions of various parts of the knuckle joint are fixed by empirical relations as given below. It may be noted that all the parts should be made of the same material i.e. mild steel or wrought iron.

Design of Knuckle joint

Dia. Of pin = 1 =d Outer dia. Of single or double eye = 2 =2d Dia. Of knuckle pinhead and collar =3 = 1.5d Thickness of single eye = t = 1.25d Thickness of fork =1 = 0.75d Thickness of collar pin =t2 = 0.5d

Question and Answers

Ans: Actual practice, the knuckle pin is loose in forks in order to permit angular movement of one with respect to the other, therefore the pin is subjected to bending in addition to shearing. By making the diameter of the knuckle.