What is 5G welding?

5G welding (Fixed horizontal position) is a tough row to hoe as it involves welding in flat, vertical, and overhead welding positions in a single weld joint. The position is not very efficient in terms of weld deposition and welder comfortable.

What is a 6g welding test?

A 6G pipe welding test as shown in the picture below is where the pipe is fixed at a 45-degree angle and welded in this fixed position. A fixed position means that once welding begins, the pipe cannot be rolled or moved. The welder has to weld all around the pipe in the same position.

What is the vertical welding 3G test?

The vertical welding certification can be taken traveling vertical up. Meaning you start on the bottom of the plate welding upward to the top. Sometimes welding vertical down meaning welding from the top down. The 3G test position covers the 1G, 2G, and 3G positions. Typically this test is done in the vertical up progress.

What is the 4G welding certification?

The 4G welding certification position is a plate in the overhead position that is beveled. This position is considered the hardest for welding plate but in reality it's not much harder then welding flat. The 4G welding test covers the 1G, 2G, and 4G positions, but does not cover the 3G position. 4G (groove) Test Position

What is 5G welding certification?

The 5G pipe welding certification position is a pipe welding in the horizontal position that is fixed and cannot be moved. The welding done is overhead, vertical, and flat with a full transition of all of those positions. This position comes in two travel directions.

What does 6G welding mean?

In welding, a 6G position requires one pipe to be positioned at a 45-degree angle to the other. Both are horizontal. This presents a very challenging position for a welder, who uses all his skills and a variety of body positions to accomplish the most difficult weld in the 6G join: the overhead weld. Video of the Day.

What is 1G 2G 3G 4G 5G 6G welding?

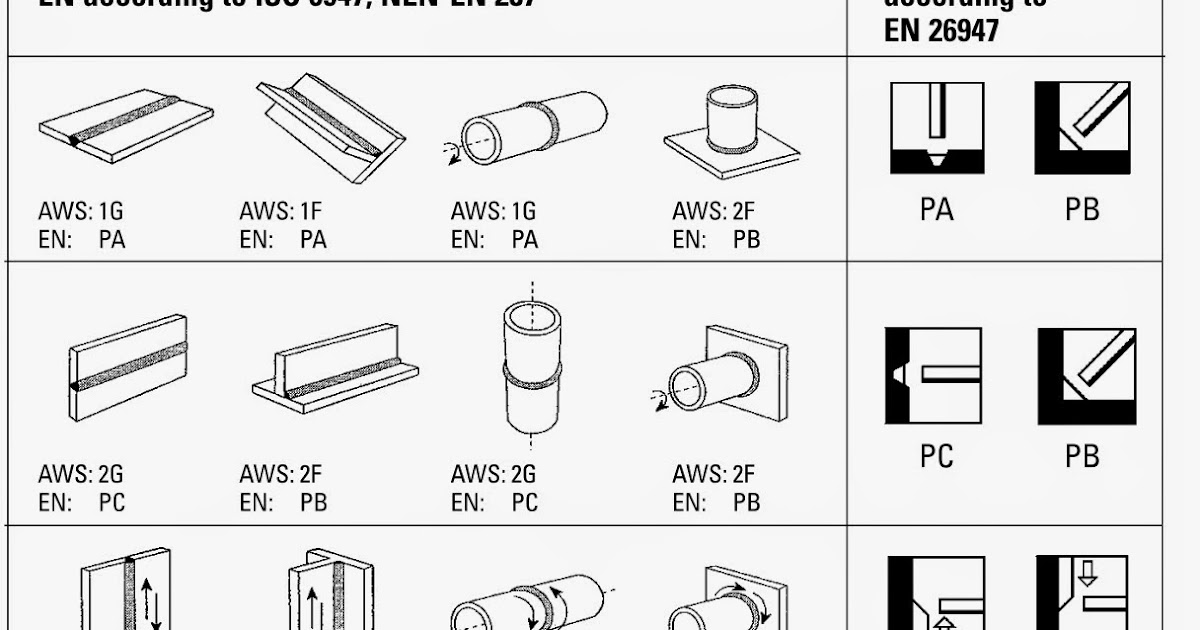

The positions of groove welds are divided into 1G, 2G, 3G, 4G, 5G and 6G, respectively indicating flat welding, horizontal welding, vertical welding, overhead welding, horizontal fixed welding of pipeline and 45 °inclined fixed welding of pipeline.

How do you weld a 5G pipe?

3:048:25SCHOFIELD WELDING 5G PIPE TEST - YouTubeYouTubeStart of suggested clipEnd of suggested clipStart on this test this is what we work on this is what we perfect. And then we move into the 6g. SoMoreStart on this test this is what we work on this is what we perfect. And then we move into the 6g. So some companies are going to have you take a 5g pipe test it's just depending.

What is the hardest welding certification?

The 6G pipe weld is one of the most difficult weld certification tests to pass because the pipe is at a 45-degree angle and immovable. Welders performing the 6G certification test must weld in all positions including horizontal, vertical and overhead, and may have to weld both right-handed and left-handed.

What is a 4G weld test?

A 4G weld test is a type of welding test that enables welders to obtain certification. What 4G weld in general covers is the position of which the welders can perform his welding services and get the job done.

How do I pass a 4G welding test?

My best advise for this 4g Stick welding testclean mill scale with a sander or grinder about 1/2" away from the bevel.take care to have an even and full 1/4" gap.set amperage to a setting that allows you to hold a very tight arc without sticking the rod.hold a tight arc and use a very slight drag angle.More items...

What is the hardest welding position?

Overhead The overhead position weldOverhead The overhead position weld is the most difficult position to work in. The welding will be performed with the two pieces of metal above the welder, and the welder will have to angle him or herself and the equipment to reach the joints.

What is 5f welding position?

0:054:027018 5/32" Stick Welding - 5F Joint Tube to Plate - YouTubeYouTubeStart of suggested clipEnd of suggested clipToday we're going to be doing a 5f joint that is a tube to plate where the axis of the tube is inMoreToday we're going to be doing a 5f joint that is a tube to plate where the axis of the tube is in the horizontal position and the plate is in the vertical position.

Why do pipeliners weld downhill?

On thinner-wall pipe, downhill welding enables operators to run “hot and fast,” increasing productivity compared to welding uphill, which is required on thicker wall pipe to increase heat input to ensure complete penetration.

What is a 6G pipe welding test?

What is a 6G Pipe Welding Test? A 6g pipe welding test is where the pipe is welded with the axis of the pipe at 45%…in a fixed position. When I say fixed position, that means that once welding begins, the pipe cannot be rolled or moved.

What is a 3G weld test?

The 3G welding certification qualifies a welder to weld flat, horizontal, and vertical or 1G, 2G, and 3G positions, also includes the 1F, 2F, and 3F positions without having to take the 1G and 2G certification. This one test qualifies you for three positions. These are the positions most commonly used in welding shops.

What is 1G welding?

The 1G pipe welding certification position is a pipe in the horizontal position and the pipe is rolled when welding. This is basically welding in the flat position. The 1G pipe welding certification is rarely used.

What is a welding certification?

Definition: Welding Certifications are technically a hands-on welder qualification test that is conducted by certified welding inspector that will determine if the person or machine can produce a sound quality weld up to the code or welding procedure needed for a Company, job site or a particular industry standard.

What size pipe do you need to weld a fillet?

These two tests usually cover all the positions and most codes allow fillet welds on pipes that are a minimum diameter of 24″.

What is the largest organization in America that certifies welders?

The largest organization in America that certifies welders is the American Welding Society . The welding certification procedures they have approved have been tested many time to ensure that if followed the welder taking the welding certification follows the rules and has the skills will pass the test.

What is a 6G restrictive ring?

The 6G restrictive ring test position is typically an 18″ restrictive ring placed 1/2″ above the weld joint. I have seen this illustrated in welding books and the AWS code. The picture is of a practice test I took and was going to get this welding certification. Unfortunately when looking for a welding procedure this test is not available. It was shown but not tested. Other codes may use it and have a procedure that is tested.

What is the coding system for plate and structural welding?

There is also a coding system to identify the welding position. The coding system for plate and structural welding is as follows: 1 is for the flat position. 2 is for the horizontal position.

How many positions are there in welding pipe?

When it comes to welding pipe there are four main positions and again they are typically groove welds. There is also a coding system to identify the positions and joint types.They are as follows:

Introduction

Magnum NDT technicians encounter several unique welding positions when performing non-destructive testing. In untrained hands, welding can be a safety hazard. That is why professional standard organizations such as ASME, AWS, ISO, JWES make rules and classifications for welding positions.

1G Position

In the 1G welding position, the pipe is in the horizontal position and can be rotated along the horizontal (X) axis. The welder's position remains stationary. Welding is performed on the top of the pipe. This is the most basic welding position that can be performed.

2G Position

In the 2G welding position, the pipe is in the vertical position and can be rotated along the vertical (Y) axis. The welder's position remains stationary. Welding is performed on the side of the pipe in a horizontal direction.

6G Position

In the 6G welding position, the pipe slopes at approximately 45° from the horizontal (X) axis or 45° from the vertical (Y) axis. The pipe is in a fixed position, so the welder must move around the pipe to perform the welding. This is an advanced welding position that requires a great deal of experience and technical expertise.

Levels of Experience

A welder's mastery over each welding position acts as a certification that qualifies him or her to perform more types of welding work. In other words, mastery over each position levels up a welder's qualifications. For instance, if a welder only a 1G position qualification, he cannot conduct welding in more advanced positions such as 2G, 5G, or 6G.

How to test welding strength?

You can also check the surface defects of weld joints. Visual Inspection. Liquid Dye Penetration. Ultra-sonic Inspection.

What is 1G welding?

In the 1G welding position or Horizontal rolled position, the pipe will be in the horizontal position, and it can be rotated along the horizontal (X) axis. The welder’s position remains stationary, means a welder performs the welding at a single plane or point, and the pipe is being rotated slowly. If the pipes are smaller in size, it can be ...

What is a pipe welder?

Pipe Welding Positions are referred to as the combination of the different positions of the welder and the job or specimen. Pipe welds are made under many different requirements and in different welding situations as per the job nature. In general, the position of the specimen is fixed, but in many cases, it can be rolled or inclined.

What is a welder's certification?

The welders must be certified in that particular weld position to perform defect-free welding. A welder’s mastery for each welding position is identified by qualification certificates and the live test. The certification qualifies him or her to perform more types of welding work.

What is the slope of a 6G pipe?

In the 6G pipe welding position, the pipe is at the slope or incline, approximately 45° from the horizontal (X) axis or from the vertical (Y) axis. The pipeline can be in a single or double offset.

Can a 1G welder rotate?

Unlike the 1G weld position, the pipe will always remain fixed, and it can not be rotated. The welder moves around the pipe outer surface in the vertical direction to perform the welding.

Is inspecting a weld joint a good idea?

Inspecting the weld joint visually is one such method, which is most cost effective , quickest, and easiest. It involves nothing quite watching the weld to discern its quality, which may be a really subjective process. It can’t be used as a reliable method for detecting internal weld defects, so this method is especially used when poor quality welds won’t put anyone or anything in problem.

What does the R in 6G welding mean?

This is another 6G weld position that is also challenging. The “R” in the name stands for restricted. In this position, welding is performed in a ring mode. What this means is that a steel plate is placed under the weld site with an inch gap.

What does the 3 digit mean in welding?

These numbers refer to the characteristics of the electrode. And the third digit in an electrode’s number designation refers to the welding position it can be used in. For instance, the number “1” means an electrode can be used in all ...

What certification do you need to weld a pipe?

In particular, pipe welders can apply for a 5G and 6G certification . These two are used for the most complex welding positions. Therefore they require more experience. The 6G certification is seen as the gold standard of welding certification. Welders with this certification can weld all-around a stationary pipe.

What is flat welding?

In the flat position, the joint or workpiece to be welded is placed under the welding torch. In this regard, the molten metal flows downward into the joint. The result is an easy to accomplish weld. This weld position can be used to perform groove, fillet, and butt welds.

What is welding position?

A welding position means the posture you need to assume towards the workpiece you are welding. In some cases, you will need to weld the workpiece in the position you find it and not adjust it in any way.

What is horizontal 2G welding?

The horizontal or 2G position is a little bit more complicated than the flat position. In this position, the workpiece is placed parallel to your body when welding. Thus the workpiece remains in front of you when welding.

Do you need to pass a qualification test to be a 3G welder?

As such, if you can weld in either the vertical or overhead positions, you qualify for a 3G or 4G certification. For the latter certification, you do not need to pass any qualification tests below those levels.

What is 6G welding?

A 6G pipe welding test as shown in the picture below is where the pipe is fixed at a 45-degree angle and welded in this fixed position . A fixed position means that once welding begins, the pipe cannot be rolled or moved. The welder has to weld all around the pipe in the same position. So, it basically covers flat, horizontal, vertical welding, and overhead in a single position. Hence considered one of the tough weld tests.

What test is required to certify a welder?

To finally certify a welder, the welder test coupon must pass a volumetric NDT such as RT or UT or can be substituted by bend test as permitted into ASME Section IX or AWS D1.1.

What is the E6010 electrode?

E6010 is a cellulose-type SMAW electrode. The arc of E6010 is very strong and there is no slag. A welding current of 60 amp to 75 amp is well suited for welding root run using 3/32’’ E6010 electrode. Watch the below video to learn about the technique for full penetration open root welding using the E6010 electrode.

What is a hot pass weld?

The hot pass is the weld pass welded as the 2nd to 3rd pass on the pipe to cover the root weld. If done correct the hot pass will turn a flat root penetration surface to a convex, good looking one. If your root weld does not have enough penetration or even some suck back a good hot pass can fix that!

What electrode diameter is used for hot pass welding?

Hot pass welding can be carried out using 1/8’’ or 5/32’’ electrode diameter. Avoiding grinding during a hot pass is recommended as many welding inspectors don’t allow grinding during hot and fill passes to judge the quality of the welders.

Is it better to do a 6G or 2G welding?

Before moving to pipe welding, it’s always better to first master the plate or structural welding. Once, you got confidence in structural welding, go for pipe welding in 2G, then 5G and then practice 6G. If you follow this, you will find 6G test much easier. Otherwise, you will struggle a lot.