How do they work? The oil nozzle atomizes the oil into very small droplets. The oil mist forms a very precise shape so it can be mixed with just the right amount of air in the oil burner. The oil mist and the air are then ignited by an ignition electrode, ensuring optimized combustion and economical fuel consumption.

What is an oil burner nozzle?

Oil burner nozzles are present in most forced combustion air burners. They are used, with an oil pump, to atomize fuel oil and allow it to burn. Atomizing is raising the pressure of the fuel and forcing it through the nozzle. The fuel comes out of the nozzle essentially vaporized. It is then mixed with air and burned.

How do nozzles work?

Let’s look at how a nozzle works, and then consider what we expect a nozzle to do. Energy is required to break up the oil into droplets. The energy is supplied by the fuel unit delivering oil to the nozzle from 100-150 PSIG for most residential applications and up to 300 PSIG for commercial applications.

Why do oil burner nozzles get Grubby?

Like Mikes oil burner nozzle shown in the photograph, oil burner nozzles get grubby during use, especially if the fuel is contaminated or if the oil burner and its electrodes are not properly adjusted.

How do I know if my oil burner nozzle is real?

Watch out: Take a look at the letters marked on the oil burner nozzle vial cap and then look at the letters and numbers stamped into the nozzle itself to be sure your nozzle is what the vial cap and color say it is. .

How are oil spray nozzles used?

Oil burner nozzles are present in most forced combustion air burners. They are used with an oil pump to atomize fuel oil and allow it to burn. Atomizing is raising the pressure of the fuel and forcing it through the nozzle. Essentially, the fuel comes out of the nozzle vaporized.

How does a furnace nozzle work?

Oil burner nozzles have the job of spraying heating oil into the combustion chamber in a spray pattern of the right size and shape to properly fit the equipment and to assure a fine spray that in turn assures as complete combustion of the heating oil as possible.

What is the difference between A and B oil burner nozzle?

The difference between an A nozzle and a B oil burner nozzle is that the B produces a solid rather than hollow core spray pattern. B nozzles are more-often used on larger or industrial oil burners. In my opinion an A nozzle will give an easier-to-set and cleaner flame in a small oil burner.

Do oil burner nozzles wear out?

If they are not regularly checked and well maintained, the nozzle will malfunction and will not last long. Usually, most parts of the furnace and the nozzle are only checked when there's a need to service it or carry out repair work, which in most cases is once or twice a year.

What are the numbers on oil burner nozzles?

On oil nozzles, the first number is gallons of oil per hour at 100psi. The second number is the apex angle (30° to 90° arc) of the oil spray cone. The letters designate the fill of the spray cone: A or H = hollow, B or ES = solid, SS = semi-solid, W = multipurpose.

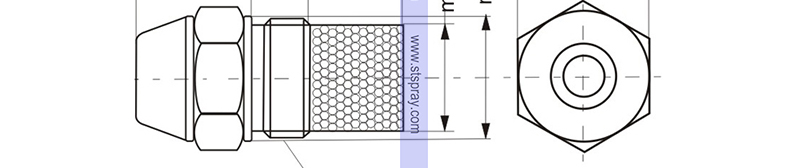

What is the purpose of the tangential slots in an oil burner nozzle?

Critical to the nozzle are the tangential metering slots, as they limit the amount of oil that can pass through the nozzle. These same slots are about the size of a human hair and for that reason they must be protected from contaminants that can be released from an aged oil tank.

How do you clean an oil burner nozzle?

Once you have access to the nozzle, you should be able to unscrew it by hand.Pour some kerosene or diesel fuel into a metal container or coffee can. ... Remove the nozzle from the fuel and wipe it clean with a lint-free cloth. ... Reattach the screw pin and filter to the nozzle.

What does W stand for on fuel oil nozzle?

"W" - Universal nozzle - Orange caps The "W" - Universal nozzle produces a spray pattern that is neither. truly hollow nor truly solid. In the lower flow rates the spray. pattern tends to be more solid.

How do you change a nozzle on an oil burner?

2:059:37How to Replace an Oil Burner Nozzle - - Biasi Boiler and Riello ... - YouTubeYouTubeStart of suggested clipEnd of suggested clipThere's only one way it can go. So the set screw set straight into that sort of divot okay. Now we'MoreThere's only one way it can go. So the set screw set straight into that sort of divot okay. Now we're gonna use a couple of wrenches. To get this out of. Here.

How can you tell if an oil nozzle is bad?

A defective, damaged or old nozzle causes soot if it fails to break up the oil correctly. Soot can also appear if the nozzle filter is clogged by dirt or rust in the oil from the tank, or by dirt or other substances accidentally transferred to it by hand during installation.

Why does my furnace nozzle keep clogging?

Inspect Your Filter The filter stops the debris from entering your fuel pump and burner, but the filter can become clogged with debris over time. When this happens, it will no longer be able to collect sludge, and the debris will form on your fuel nozzle.

What causes oil burner puff back?

A puff back occurs when an oil burner doesn't ignite right away and as a consequence fumes build up in the furnace. The fumes cause an explosion inside the burner chamber, which vaporizes and expels soot throughout a home or business, covering walls, baseboards, furniture and floors in oily toxic soot.

Understanding combustion problems

If a burner seems to have combustion issues, it doesn’t always mean the burner is malfunctioning on its own. Sometimes, poor airflow around the system can be the culprit. Poor airflow can be caused by a variety of factors:

Are you looking for a reliable heating oil supplier?

If you’re looking for affordable heating oil from a fuel supplier that offers fast and hassle-free deliveries, contact Lawman’s Oil today.

What is the job of oil burner nozzles?

Oil burner nozzles have the job of spraying heating oil into the combustion chamber in a spray pattern of the right size and shape to properly fit the equipment and to assure a fine spray that in turn assures as complete combustion of the heating oil as possible.

What type of nozzle is used for oil burners?

Another common oil burner nozzle pattern is the Type W nozzle that is "in between" a hollow-cone and a solid-cone spray pattern. Type W nozzles are sometimes substituted for an A or B spray pattern nozzle.

Why is my oil burner sooting?

If the burner is sooting abnormally AND has a nozzle that's within the range permitted by the manufacturer for your oil burner, the tech will look for any of quite few other causes of oil burner sooting like air leaks, dirty oil, wrong pressure, poor combustion air, wrong draft settings, bad electrodes.

Why is my oil burner grubby?

Like Mikes oil burner nozzle shown in the photograph, oil burner nozzles get grubby during use, especially if the fuel is contaminated or if the oil burner and its electrodes are not properly adjusted.

What does 80°A mean in spray?

Each spray pattern is designated by a letter stamped into the nozzle on one of its facets. So the nozzle whose data we showed above, a Delavan 80°A means the nozzle sprays at an 80 degree angle with spray pattern "A" which we know is hollow.

What temperature does a fuel nozzle work at?

The fuel may be 40-50°F, the nozzle may operate at temperatures up to 250°F and the off cycle soak temperature may climb to nearly 300°F in some appliances.

What happens if a nozzle gets dirt in it?

If the orifice gets dirt in it or becomes scratched, it will not function properly. Inspect the nozzle adapter before installing the nozzle. If there are deep grooves cut into it from previous nozzles, replace it. Those grooves or a scratched surface are a potential source for a leak.

How does the swirl chamber work?

The nozzle, through the swirl slots, swirl chamber and orifice converts the energy from pressure to velocity. Approximately half of the pressure is converted or dropped across the swirl slots and chamber. At this point, as their name implies, the swirl slots cause the oil to swirl in the swirl chamber.

Why is it so difficult to generalize about nozzles?

Due to the lack of standards to define the qualities that we give a nozzle, it is difficult to even generalize about their use and application. In the laboratory many of the tests performed are conducted to select the proper nozzle.

What causes oil to form a hollow tube?

At this point, as their name implies, the swirl slots cause the oil to swirl in the swirl chamber. The swirling oil is forced toward the orifice, causing the oil to form a hollow tube . As this hollow tube exits the orifice, a cone shaped film of oil develops.