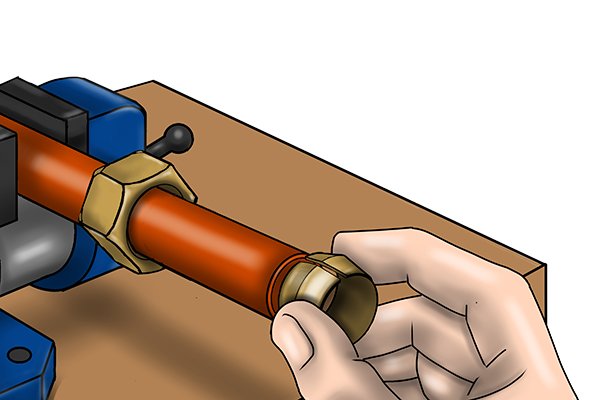

Tighten down the handle of the sleeve puller. This will draw the compression nut forward on the pipe, pulling the compression sleeve free. If the sleeve is very tight, it may be necessary to hold the puller with one hand and screw the bolt in with pliers or a wrench.

How do you remove a stuck compression nut?

Place the compression nut in the jaws of a second crescent wrench, tightening the wrench to the nut. Firmly hold the wrench handle that is attached to the fitting's body. Turn the wrench's handle attached to the compression nut clockwise until the nut loosens. Remove both wrenches.

What is a compression sleeve puller?

A compression sleeve puller is a specialty plumbing tool designed to help remove the brass compression sleeves on various compression fittings, such as fixture shutoff valves. Another specialty tool that is sometimes confused with a compression sleeve puller is the cartridge puller.

How do you use a crescent wrench for compression fittings?

Place the compression nut in the jaws of a second crescent wrench, tightening the wrench to the nut. Firmly hold the wrench handle that is attached to the fitting's body. Turn the wrench's handle attached to the compression nut clockwise until the nut loosens.

How do you tighten a plastic compression fitting?

Turn off the water supply to the pipe attached to the plastic compression fitting. Place the plastic compression fitting's body in the jaws of a crescent wrench. Tighten the wrench's jaws to the fitting's body. Place the compression nut in the jaws of a second crescent wrench, tightening the wrench to the nut.

How do you use a compression nut removal tool?

0:251:30Easy Compression Ring Removal - Superior Tool Handle & Sleeve PullerYouTubeStart of suggested clipEnd of suggested clipAnd the compression ring that has probably been on there for many years simply attach the nut to theMoreAnd the compression ring that has probably been on there for many years simply attach the nut to the threaded portion of the gold ferrule on the tool. And then turn the handle in a clockwise motion.

How do you release compression fittings?

1:413:25How to Remove and Replace Compression Ring EASY! - YouTubeYouTubeStart of suggested clipEnd of suggested clipYou can see here as you start to twist it it cuts the pipe. But I got around I'm gonna tighten thisMoreYou can see here as you start to twist it it cuts the pipe. But I got around I'm gonna tighten this some more and then keep using see here I did three times turning it and tightening.

How do you remove a compression nut and ferrule?

1:505:11How to Remove a Stuck Ferrule from a Copper Pipe in Seconds - YouTubeYouTubeStart of suggested clipEnd of suggested clipAnd that's the beauty of this tool it's going to screw in just like the water supply valve screws inMoreAnd that's the beauty of this tool it's going to screw in just like the water supply valve screws in to the compression nut. Okay. So there's a disc here. Okay you got it screw.

How do you unscrew a compression valve?

2:258:08How To Remove/Install a LEAKY/NEW SHUT-OFF Valve ...YouTubeStart of suggested clipEnd of suggested clipThen you want to remove the valve by holding the body with one wrench and undoing the nut withMoreThen you want to remove the valve by holding the body with one wrench and undoing the nut with another.

Is it OK to reuse compression fittings?

Reusable Compression Fittings: They are safe to be reused and apply to half the movement of the pipe outward from the fitting. In hydraulic process, compression fittings basically assure some secure fit in pipe connections. Leaks are only possible if they are not properly installed to each end of the fluid line .

How tight should a compression fitting be?

Hold the compression fitting body tightly with a pair of grips and tighten the nut with a spanner. Its often said in the trade to not over tighten a compression fitting, leaving you more thread in the case of a leak and not distorting the olive or fitting. Generally a nut will need one whole turn after hand tightening.

What happens when you over tighten a compression fitting?

The tubing will bulge and stick inside of the fitting if the ferrules are overly secure. If you can't disassemble the valve or fitting, it's a good indicator that the connection is much too tight. The only thing to do in this instance is to remove and replace the fitting in question.

How do you use a compression fitting?

0:432:26How to Install a BrassCraft® Compression Fitting - YouTubeYouTubeStart of suggested clipEnd of suggested clipSlide the compression fitting onto the tube until the tube bottoms out a drop of lubricating oil orMoreSlide the compression fitting onto the tube until the tube bottoms out a drop of lubricating oil or thread sealant will ease not assembly thread the nut onto the fitting hand-tighten.

How to tighten a compression nut?

Place the compression nut in the jaws of a second crescent wrench, tightening the wrench to the nut. Firmly hold the wrench handle that is attached to the fitting's body. Turn the wrench's handle attached to the compression nut clockwise until the nut loosens. Advertisement.

How to remove a compression nut from a pipe?

Hold the fitting's body in one hand and unscrew the loosened compression nut by hand. Slide the nut along the pipe. Pull the pipe away from the compression body. Slide the ring off the end of the pipe and discard it. Slip the compression nut off the pipe and screw it onto the fitting's body. Repeat the entire process to remove the pipe from ...

What is a plastic compression fitting?

Plastic compression fittings are designed to create water tight joints that require no heat or cement. Each fitting consists of the fitting's body, a compression ring (known also as a ferrule) and a compression nut.

Can compression fittings be reused?

Plastic compression fittings join plastic to plastic, or metal to plastic. Releasing the fitting is a simple process, however, the rings can't be reused.