How do you calculate rivet spacing? Rivet spacing is measured between the centerlines of rivets in the same row. The minimum spacing between protruding head rivets shall not be less than 31⁄2 times the rivet diameter. The minimum spacing between flush head rivets shall not be less than 4 times the diameter of the rivet.

How to calculate the length of a rivet?

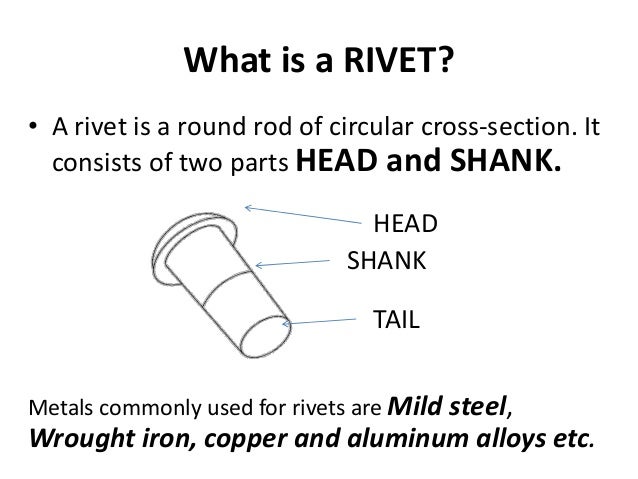

The height must extend to 0.3 times the diameter of the shank. With all mentioned parameters, you can calculate the desired length of the rivet. The allowance is normally about 1.5D. For example, two pieces of 0.050 inch (1.27 mm) sheet are to be riveted together.

What is rivet pitch and spacing?

Rivet spacing, also referred as rivet pitch, is the distance between the rivets in the same row, and is measured from the rivet center to the rivet center. Likewise, people ask, what is edge margin?

How do you find the area of a hollow rivet?

If the rivet is hollow, compute the area using this formula: A = Pi x ( (D / 2)^2 - ( (D - t)/2)^2). Replace D by the (outer) diameter of the rivet, and t by the thickness of the rivet's wall, measured using the calipers.

How do you calculate shear force on a rivet?

Calculate the shear strength of your rivets by evaluating this formula: F = A x S. Replace S by the shear strength of the metal found in Step 2. Your rivets can tolerate shear forces of up to F Newtons before breaking apart.

How far apart should rivets be?

Rivet spacing is measured between the centerlines of rivets in the same row. The minimum spacing between protruding head rivets shall not be less than 31⁄2 times the rivet diameter. The minimum spacing between flush head rivets shall not be less than 4 times the diameter of the rivet.

How do you calculate the number of rivets needed?

The Number of rivets per pitch length given strength of joint for butt joint with double cover plates formula is defined as a number of rivets required in a joint is calculated using Number of Rivets Per Pitch = Strength of joint/((2*(pi/4)*(Diameter of rivet^2)*Safe shear stress)).

How do you lay a rivet pattern?

5:346:39Rivet Layout | A&P - YouTubeYouTubeStart of suggested clipEnd of suggested clipSpace the rivets four to seven rivet diameters apart if adjacent rivets are at right angles to eachMoreSpace the rivets four to seven rivet diameters apart if adjacent rivets are at right angles to each other space them five to seven rivet diameters apart if the rivets are parallel to each other.

What is the minimum lap distances should be kept spacing of rivets?

The distance from the edge of the metal to the center of any rivet should be at least twice the diameter of the rivet. The purpose of this is to prevent the splitting of the edges. The maximum distance from the edge should not be more than ten times the thickness of the plate.

What is the minimum distance between the rivets to avoid buckling?

Rivet spacing is measured between the centerlines of rivets in the same row. The minimum spacing between protruding head rivets shall not be less than 31⁄2 times the rivet diameter.

How do you choose a rivet diameter?

A general rule is that the rivet should have a diameter of at least 3 times the thickness of the thickest sheet that is being joined. According to the military standard, so the bucked counter head diameter of the rivet joint must be larger than 1.4 times the diameter of the shank.

How do you calculate edge distance for rivets?

2:276:16Edge Distance for Rivet Holes - YouTubeYouTubeStart of suggested clipEnd of suggested clipIf our rivet size is 5/32 what is the minimum edge distance. We can use if we use the two timesMoreIf our rivet size is 5/32 what is the minimum edge distance. We can use if we use the two times diameter that would be 5/16 of an inch as measured from the center of the rivet to the edge if.

Why is rivet spacing important?

If rivets are placed too close to the edge the sheet may crack. If they are spaced too far the sheet is likely to turn up at the edges. It is good practice to lay out the rivets a little further from the edge so that the rivet holes can be oversized without violating the edge distance minimums.

What is 4D rivet spacing?

The number of rivets that may be placed in a row is then one more than the row length divided by the rivet spacing used, since the row length both starts and ends with a rivet. In the case of 3D rivet spacing, that means 42 rivets per row maximum. 4D spacing accommodates 32 rivets per row maximum.

What is the maximum distance from the center of the first rivet to the edge?

Right Answer is: A Margin or marginal pitch is the distance between the centre of rivet hole to the nearest edge of the plate. Maximum margin should be two times the diameter of the rivet.

What is the distance between the centers of neighboring rivets in the same row called?

Gauge distance: The distance between centers of any two adjacent rivets parallel to the direction of force is called pitch.

What are the rules for minimum and maximum edge distance?

The maximum distance from the edge of the material to the center of a rivet hole is called the edge distance. The minimum edge distance is 2 diameters of the shank of the rivet being used. Distance between rivets in the same row is called pitch. Minimum pitch is 3 diameters of the shank of the rivet.

How far apart should a head rivet be?

The rivet diameter of a protruding head rivet is 3⁄32- inch. Multiply 2 times 3⁄32-inch to obtain the minimum edge distance, 3⁄16-inch, add 1⁄16-inch to yield the preferred edge distance of 1⁄4-inch.

How to determine edge distance?

Two methods for obtaining edge distance: 1 The rivet diameter of a protruding head rivet is 3⁄32- inch. Multiply 2 times 3⁄32-inch to obtain the minimum edge distance, 3⁄16-inch, add 1⁄16-inch to yield the preferred edge distance of 1⁄4-inch. 2 The rivet diameter of a protruding head rivet is 3⁄32-inch.

How big should a rivet be?

According to the military standard, so the bucked counter head diameter of the rivet joint must be larger than 1.4 times the diameter of the shank.

Why do people use rivets?

There are several reasons for using the riveting method, among which the low cost of installation, the lower requirements for hole preparation, high reliability, light and strong joint due to the low weight, resistance to fatigue due to the high elasticity and durability.

What happens if you punch a rivet too hard?

If the punch is too hard, the mark will be too large and the metal will be distorted.

Is riveting a weldable material?

In spite of all the advances in fastening methods, such as gluing and tightening, riveting is still one of the main method used by the aircraft assembly industry and also by other lightweight construction industries where the high strength sheet metal is not weldable.

How to calculate shear strength of rivets?

Calculate the shear strength of your rivets by evaluating this formula: F = A x S. Replace S by the shear strength of the metal found in Step 2. Your rivets can tolerate shear forces of up to F Newtons before breaking apart.

Why is it important to know how much load a rivet can take before the stress forces break the metal?

Because the parts held by a rivet can pull apart from each other with considerable force, it is important to know how much load a rivet can take before the stress forces break the metal. In particular, the shear strength of a rivet measures the amount of force that can be applied transversally (i.e., perpendicular to the main axis of the rivet) ...

How far apart should a head rivet be?

The rivet diameter of a protruding head rivet is 3⁄32- inch. Multiply 2 times 3⁄32-inch to obtain the minimum edge distance, 3⁄16-inch, add 1⁄16-inch to yield the preferred edge distance of 1⁄4-inch.

How close can a rivet be to an edge?

Similarly, it is asked, how close can a hole be to an edge? It is recommended that the minimum distance between the extruded holes to part edge should be at least three times the thickness of sheet.