What is the yoke on a valve made of?

Over many valves, The yoke and the bonnet are designed as a one-piece construction. The top side of the yoke consists of the yoke nut and yoke bushing. To withstand forces, moments, and torque developed by the actuators, the Yoke is made hard enough.

What is a yoke valve bushing?

The top of the Yoke holding a Yoke nut, stem nut, or Yoke bushing and the valve stem passes through it. A Yoke usually has openings to allow access to the stuffing box, actuator links, etc.. Click to see full answer. Herein, what is outside screw and yoke valve?

What is the difference between a yoke and a DIN valve?

Yoke and DIN Valves Are Found on Different Kinds of Tanks Yoke valves are common throughout North America and recreational tourist destinations. They are standard on most Aluminum 80 cubic foot tanks (Al 80). DIN valves can handle higher pressures than yoke valves and are used on high-pressure tanks.

What is a scotch yoke valve actuator?

A scotch yoke valve actuator is engineered to automate all types of quarter-turn valves (butterfly, ball, plug, and damper) with various torque profiles to provide a “best fit” for every application.

Where is the yoke on a valve?

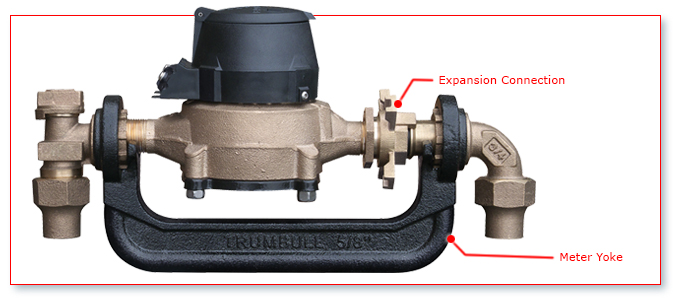

The yoke is a clamp-type mounting, which is placed over the tank valve and then tightened into place. The DIN is a threaded valve, wherein you screw the regulator into the tank valve. On the yoke valve, the main O-ring that seals the tank valve to the regulator first stage is placed on the tank valve.

What is valve bonnet?

An assembly including the part through which a valve plug stem moves and a means for sealing against leakage along the stem. It usually provides a means for mounting the actuator. Sealing against leakage may be accomplished by packing or a bellows.

What is valve and its function?

A valve is a device or natural object that regulates, directs or controls the flow of a fluid (gases, liquids, fluidized solids, or slurries) by opening, closing, or partially obstructing various passageways. Valves are technically fittings, but are usually discussed as a separate category.

What is gate valve?

A gate valve is generally used to completely shut off fluid flow or, in the fully open position, provide full flow in a pipeline. Thus it is used either in the fully closed or fully open positions. A gate valve consists of a valve body, seat and disc, a spindle, gland, and a wheel for operating the valve.

What is valve backseat?

What is a backseat? A backseat is a seating arrangement inside the bonnet. It provides a seal between the stem and bonnet and prevents system pressure from building against the valve packing when the valve is fully open. Back seats are often applied in gate and globe valves (source: wermac.org).

What is valve schedule?

The Valve Schedule tool will give you a list of information about the valves (or stations) used in the design, the types of heads connected to them, their size, flow, pressure required at the valve and at the POC, and the precipitation rate of the heads on that valve.

What is the parts of valve?

Regardless of type, all valves have the following basic parts.. the body, bonnet, trim (internal elements), actuator, and packing.

Why is valve called valve?

Valve's Ray Ueno stated he worked with Gabe Newell and their colleagues to develop the "guy in the logo" when they decided to call the company "Valve" around 1995-1996, and needed to develop the visual brand vocabulary to go along with it.

What is valve size?

When sizing a control valve, the most common approach is to calculate the flow coefficient, Cv which is a measure of the capacity of the valve body and trim. A valve Cv can be described as the number of gallons per minute (GPM) at 60oF (15.5oC) that will pass through a valve with an associated pressure drop of 1 psi.

What is a ball value?

A ball valve is a flow control device which uses a hollow, perforated and pivoting ball to control liquid flowing through it. It is open when the ball's hole is in line with the flow inlet and closed when it is pivoted 90-degrees by the valve handle, blocking the flow.

What is valve and types?

Valves are for starting or stopping flow, regulating or throttling flow, preventing back flow or relieving and regulating pressure in fluid or gaseous handling applications. Common valve types include: Ball,Butterfly,Check, Diaphragm, Gate, Globe, Knife Gate, Parallel Slide, Pinch, Piston, Plug, Sluice, etc.

What is controlled valve?

A control valve regulates the rate of fluid flow as the position of the valve plug or disk is changed by an actuator. Control valves are used to maintain a process variable as close as possible to the desired set point. Controller set points are typically flow rate, pressure, and temperature.

What are Valves?

A valve is a device for controlling the passage of fluid or air through a pipe, duct, etc, by opening, closing, or partially obstructing various passageways. The simplest valves are one-way-flap mechanisms that allow flow in one direction and shut with back-flow pressure to stop flow in the direction of origin.

What is the function of a valve?

A valve is a device or natural object that regulates, directs, or controls the flow of a fluid by opening, closing, or partially obstructing various passageways.

Parts of Valves

All valves have the following basic parts: the body, bonnet, trim (internal elements), actuator, and packing. The basic parts of valves are:

Valve Opening Methods Explained

While many valves accomplish similar goals, how they do so mechanically can vary. How a valve opens and closes will not only impact the overall performance but also determine how much control you have over the flow and how quickly the valve can operate.

Types of Valves

Valves feature a range of characteristics, standards, and groupings the help to give you an idea of their intended applications and expected performance. Valve designs are one of the most basic ways to sort the huge range of valves available and find a good fit for a project or process.

Classification of Valves

The following are some of the commonly used valve classifications, based on mechanical motion:

The Most Common Control Valve Symbols

The control valve symbols on a P&ID differ depending on the type of valve specified for the application. Each P&ID has its own legend that identifies the symbols for the various equipment.

Valve Yoke and Yoke Nut

A Yoke connects the valve body or bonnet with the actuating mechanism. The top of the Yoke holding a Yoke nut, stem nut, or Yoke bushing and the valve stem passes through it. A Yoke usually has openings to allow access to the stuffing box, actuator links, etc..

Valve Actuator

Hand-operated valves are usually equipped with a handwheel attached to the valve's stem or Yoke nut which is rotated clockwise or counter clockwise to close or open a valve. Globe and gate valves are opened and closed in this way.

How does a Scotch YOKE work?

How do they work? A scotch yoke actuator typically consists of a crank and piston system in a hollow cylinder. Pressure is applied to a side of the piston inside the cylinder. As a result, force is generated which moves the piston along the axis of the cylinder to rotate the actuator stem 90° with pilot air application.

Why do butterfly valves need more torque?

A valve usually requires a higher torque on the start and the end of its stroke. For a butterfly valve to start opening from a completely closed position , higher torque is required to overcome the friction between the seat and valve body.

Why do you need lower torques in a valve?

Lower torques are needed to keep the valve moving in the middle section of the valve stroke. The torque output of a scotch-yoke actuator changes as a function of stroke position, resulting in higher torque at the beginning and end of the stroke (fig 4). (fig4)

What is a valve?

A valve is a mechanical device that controls the flow of fluid and pressure within a system or process. A valve controls system or process fluid flow and pressure by performing any of the Following functions.

What are the parts of a valve?

Regardless of type, all valves have the following basic parts: the body, bonnet, trim (internal elements), actuator, and packing. The basic parts of a valve are illustrated in Figure 1. Control Valves mainly have Two parts: 1) Actuator Part. 2) Body Part for easy understanding.

Why does the stem rise above the actuator?

For a rising stem valve, the stem will rise above the actuator as the valve is opened. This occurs because the stem is threaded and mated with the bushing threads of a yoke that is an integral part of, or is mounted to, the bonnet. There is no upward stem movement from outside the valve for a non rising stem design.

What are some examples of valves?

Examples of the common types are the globe valve, gate valve, ball valve, plug valve, butterfly valve, diaphragm valve, check valve, pinch valve, and safety valve.

What is spring in actuator?

It will act as a force for Actuator Stem Cell and a strong wind from the opposite direction to the plate Diaphragm. Actuator Stem is interconnected with Actuator Valve Stem.

What is the purpose of packing valves?

Most valves use some form of packing to prevent leakage from the space between the stem and the bonnet. Packing is commonly a fibrous material (such as flax) or another compound (such as teflon) that forms a seal between the internal parts of a valve and the outside where the stem extends through the body.

What is the function of a valve plug?

Valve Plug is essential to use the force of fluid flow. And determine the flow properties as Linear, Equal Percentage or Quick Openning. Seat Ring is a component that is part of Valve Body and given the size of the Rated Cv of the valve and which supports Plug and Plug and Seat Ring must be close together.

What is an OS&Y Valve & how does it function?

An OS&Y valve (outside screw & yoke) functions by opening and closing via a gate, which lowers both in and out of the valve. When the handle is turned clockwise the gate will close preventing any water from traveling through the valve. When the handle is turned counterclockwise, the gate will open allowing the water to flow through freely.

What is the key difference between an OS&Y and a Gate Valve?

OS&Y valves visibly show whether the valve is opened or closed which differs from a domestic water service where you can simply turn on the shower or sink to test its functionality. When the stem of the OS&Y is raised out of the body you know the water is on.

When are OS&Y Valves Required?

OS&Y valves visibly show whether the valve is opened or closed which differs from a domestic water service where you can simply turn on the shower or sink to test its functionality. When the stem of the OS&Y is raised out of the body you know the water is on.

Does your Fire Sprinkler System require a tap or a wet connection on the city main?

If you are installing a new 2”copper main or a main smaller in size, you will be required to install the same size tap connection on the city main. This differs from a Wet Connection on a domestic water service where the tap connection would be one size smaller than the pipe.

What is a yoke valve?

Yoke valves are common throughout North America and recreational tourist destinations. They are standard on most Aluminum 80 cubic foot tanks (Al 80). DIN valves can handle higher pressures than yoke valves and are used on high-pressure tanks. They are also found on Al 80's in Europe and some other parts of the world.

How to attach a yoke to a tank?

To attach a yoke-style first stage to a tank, a diver fits the metal brace over the tank valve and then tightens the yoke screw to clamp the first stage firmly in place.

What is the o-ring on a tank regulator?

If there is an o-ring in the part of the regulator that attaches to the tank, you have a DIN regulator. If there is no o-ring visible on the regulator, but your tank has an o-ring, then you have a yoke regulator.

Where is the O ring on a DIN tank?

This causes a major leak. In contrast, the o-ring for the DIN system is located at the end of the post that threads into the tank valve.

Can a DIN regulator be used on a yoke?

DIN regulators can be converted to the yoke system and yoke regulators can be converted to the DIN system with the appropriate service kit. This is a quick conversion and is easy for a knowledgeable service technician. In addition, adaptors are available to use DIN regulators on yoke tanks and vice-versa.

Can you knock a yoke regulator?

Because the o-ring is in the regulator, a diver with his own regulator brings his own o-ring to the dive and can be certain not to be stuck with worn out, damaged o-rings sometimes found on rental yoke-valve tanks. DIN regulators can be designed to withstand higher pressures than yoke regulators. It is possible to knock a yoke regulator off ...

Can you use DIN regulators on yoke tanks?

In addition, adaptors are available to use DIN regulators on yoke tanks and vice-versa. The only problem is that the yoke adaptor for a DIN regulator is a little bulky and may cause the regulator first stage to stick out and bump a diver's head.