What does it mean for material to be a brittle?

A material is brittle if, when subjected to stress, it fractures with little elastic deformation and without significant plastic deformation. When used in materials science, it is generally applied to materials that fail when there is little or no plastic deformation before failure.

What is the difference between ductile and brittle material?

- Cast iron

- Ceramics such as glass, cement, concrete, etc.

- Stone

- Ice

What are some examples of brittle material?

- uncooked pasta

- cookies

- chalk

What is the most brittle material?

steel. …is the hardest and most brittle form of steel. What is a brittle material has? 1 Brittleness Brittleness describes the property of a material that fractures when subjected to stress but has a little tendency to deform before rupture.

What is brittle material?

Why are ceramics so brittle?

About this website

What is brittle material example?

Brittle materials include glass, ceramic, graphite, and some alloys with extremely low plasticity, in which cracks can initiate without plastic deformation and can soon evolve into brittle breakage.

What is called brittle?

having hardness and rigidity but little tensile strength; breaking readily with a comparatively smooth fracture, as glass. easily damaged or destroyed; fragile; frail: a brittle marriage.

What is the meaning of brittle in metal?

A material is brittle if, when subjected to stress, it fractures with little elastic deformation and without significant plastic deformation. Brittle materials absorb relatively little energy prior to fracture, even those of high strength. Breaking is often accompanied by a sharp snapping sound.

What is ductile and brittle material?

Ductile materials are those materials which show large plastic range beyond elastic limit. eg:- copper Iron Brittle materials are those materials which show very small plastic range beyond elastic limit. eg:- Cast Iron Glass.

Is steel a brittle material?

steel. …is the hardest and most brittle form of steel. Tempering martensitic steel—i.e., raising its temperature to a point such as 400° C and holding it for a time—decreases the hardness and brittleness and produces a strong and tough steel.

Is glass brittle?

The amorphous structure of glass makes it brittle. Because glass doesn't contain planes of atoms that can slip past each other, there is no way to relieve stress. Excessive stress therefore forms a crack that starts at a point where there is a surface flaw. Particles on the surface of the crack become separated.

What is brittle material class 11?

A material is said to be brittle material if, when subjected to the stress, it breaks with little elastic deformation and without any significant plastic deformation.

Is iron a brittle?

Iron is a brittle, hard substance, classified as a metal in Group 8 on the Periodic Table of the Elements. The most abundant of all metals, its pure form rapidly corrodes from exposure to moist air and high temperatures.

Is copper a brittle?

Copper is malleable and ductile but brass is hard and brittle.

What is brittle or ductile?

Ductile substances can be easily hammered or stretched into thin wires without breakage. This physical property is explained as ductility. Brittle substances are liable to break easily. These substances are hard, and cannot be hammered or stretch like ductile substances; instead, they break.

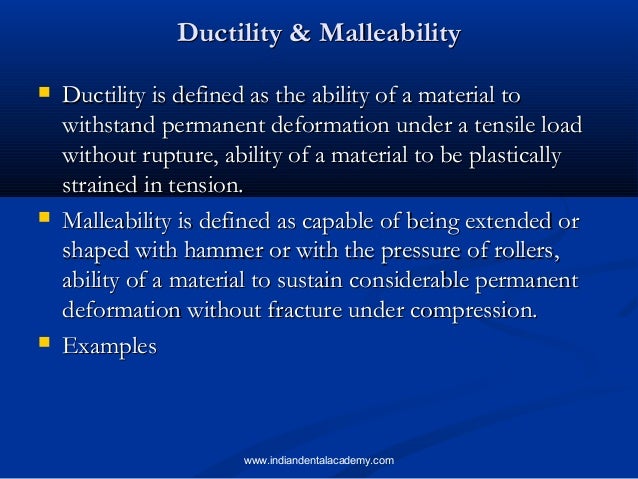

What is ductile material?

Ductility is the ability of a material to be drawn or plastically deformed without fracture. It is therefore an indication of how 'soft' or malleable the material is.

What is the meaning of ductility?

: the quality or state of being ductile especially : the ability of a material to have its shape changed (as by being drawn out into wire or thread) without losing strength or breaking When certain alloys are added to metal, hardness and strength can be improved without decreasing the ductility. —

What materials are classified as Brittle Plastic? - IFSQN

What materials are classified as Brittle Plastic? - posted in Foreign Body Prevention: What exactly is a brittle plastic and what materials fall under that classification? I need to create aglass and brittle plastic registry, but I'm not sure which plastics are technically considered brittle?

What is a Brittle Metal? - Rock and Mineral Planet

Metal is not considered to be brittle if it can stretch and pull to deform it. This would mean the metal is ductile or malleable. You often see metal being put under high temperatures to accomplish the deformation of metal.

Brittle Material - an overview | ScienceDirect Topics

Brittle materials include glass, ceramic, graphite, and some alloys with extremely low plasticity, in which cracks can initiate without plastic deformation and can soon evolve into brittle breakage. Apparently, the microcutting model is not suitable for such materials. It has been experimentally shown that as a single particle impacts the brittle material, cracks generally occur at those ...

What is brittle material?

A brittle material is also known as a material having low ductility. A stress-strain curve for brittle and ductile materials is shown in the figure below. We will talk more about ductile materials in the next section.

Why are ceramics so brittle?

In metals, their metallic bonds allow the atoms to slide past each other easily. In ceramics, due to their ionic bonds, there is a resistance to the sliding.

What is the difference between brittle and ductile materials?

Ductile materials have a fracture strength lower than the ultimate tensile strength (UTS), whereas in brittle materials the fracture strength is equivalent to the UTS. If a ductile material reaches its ultimate tensile strength in a load-controlled situation, it will continue to deform, with no additional load application, until it ruptures.

What is brittle fracture?

Brittle fracture occurs suddenly and catastrophically without any warning. This is a consequence of the spontaneous and rapid crack propagation. However, for ductile fracture, the presence of plastic deformation gives warning that failure is imminent, allowing preventive measures to be taken.

What is ductility in a material?

Ductility is the ability of a material to be elongated in tension. Ductile material will deform (elongate) more than brittle material. Ductile materials show large deformation before fracture. In ductile fracture, extensive plastic deformation (necking) takes place before fracture.

What is brittleness in engineering?

What is Brittleness – Definition. In materials science, brittleness is understood as the lack of ductility. For engineers, the understanding of the difference between brittle and ductile material is of the highest importance. In materials science, brittleness is understood as the lack of ductility.

Which is better, a ductile or a brittle fracture?

Ductile fracture is better than brittle fracture, because there is slow propagation and an absorption of a large amount energy before fracture. In some materials, the transition is sharper than others and typically requires a temperature-sensitive deformation mechanism.

What is cleavage in crystalography?

In crystalography, cleavage is the tendency of crystalline materials to split along definite crystallographic structural planes. Any fracture process involves two steps, crack formation and propagation, in response to an imposed stress. The mode of fracture is highly dependent on the mechanism of crack propagation.

What are brittle materials?

Brittle materials include glass, ceramic, graphite, and some alloys with extremely low plasticity, in which cracks can initiate without plastic deformation and can soon evolve into brittle breakage. Apparently, the microcutting model is not suitable for such materials. It has been experimentally shown that as a single particle impacts the brittle material, cracks generally occur at those impact positions that are flawed, as the particle impact velocity reached a certain value, the threshold velocity. The shape of the particle has a tremendous effect on crack initiation. Normally, two types of cracks (traverse and radial) appear on the surface ( Xiaohe & Jing, 1984 ). Fig. 1.29 shows the crack propagation model.

What is the difference between brittle and ductile materials?

The difference between brittle materials and ductile materials in a tensile test is illustrated schematically in Figure 17.14. Brittle materials displace elastically up to the elastic limit and then fail with very little plastic flow. In contrast, ductile materials yield and may work harden while undergoing substantial plastic flow allowing strain many times larger than the elastic strain. Single-phase alloys and pure metals are more ductile than materials containing second phases or inclusions. The reason for the difference in behaviour is that in brittle materials, crack growth predominates over plastic flow as the yield mechanism. In many engineering materials, yield takes place by a combination of plastic flow and crack propagation. For high density structural ceramics such as silicon nitride, the material behaviour is extremely brittle. Although the material has high fracture strength, there is negligible plastic flow before failure.

How does spalling affect rock?

Brittle material is broken off from or close to a free surface where a tensile stress wave travels and makes the material fractured under dynamic tensile loading. This form of fracture is called spalling, which has been described in the chapter: Stress Waves. On one hand, spalling is important in rock blasting since rock can be easily destroyed under tensile loading, as described previously. In other words, spalling plays a positive and important role in rock fragmentation. On the other hand, spalling causes safety problems in underground mining. In this aspect, spalling may happen either close to blast source or far from it. In the region near the blast source, spalling can be serious, particularly if blasting is not well designed. As shown in Fig. 23.1, one large area of rock in the roof of a production drift was broken off due to spalling. In this case, the safety of the people who work in the field becomes worse since there are probably some hanging stones in the roof and they may fall down at any time. Moreover, if the situation is very bad, scaling must be carried out, which of course requires more work and costs more money. Spalling may occur at a place far from the blast source as long as the blast-induced tensile wave is strong enough to fracture rock. As shown in Fig. 23.2, spalling happened at several places far from the blast source. We can see several stones at different places on the floor of the drift. Notice that those stones are not small since the drift is 7-m wide. This type of spalling may appear very far from the blast source, even in neighboring drifts.

Why is spalling important in rock blasting?

On one hand, spalling is important in rock blasting since rock can be easily destroyed under tensile loading, as described previously. In other words, spalling plays a positive and important role in rock fragmentation. On the other hand, spalling causes safety problems in underground mining.

Why do cracks form?

Cracks may also develop due to large grain size and weak grain boundaries in some materials or along inter-crystalline cleavage planes in other materials. Cracks that propagate along grain boundaries may sometimes be arrested by tough elements at the grain boundaries.

What is basalt used for?

Basalt is a volcanic rock, which can be cast into sections and used for lining surfaces, and although widely used for lining chutes and hoppers, it is often used for straight pipeline and bends. After casting, the material is heat treated to transform it from an amorphous into a crystalline structure.

What is Ni hard?

Ni-Hard is an abrasion-resistant white cast iron. It contains about 6% nickel, 8.5% chromium, 1.7% silicon, and 0.5% manganese, and the structure can be refined by chill casting. The material has a Brinell hardness of 550 to 650, which is equivalent to a Vickers hardness of about 750 kg/mm2.

Fracture of Material

A fracture is the separation of an object or material into two or more pieces under the action of stress. Engineers need to understand fracture mechanisms. There are fractures (e.g. brittle fracture ), which occur under specific conditions without warning and can cause major damage to materials.

Ductile–brittle Transition Temperature

As was written, the distinction between brittleness and ductility isn’t readily apparent, especially because both ductility and brittle behavior are dependent not only on the material in question but also on the temperature (ductile-brittle transition) of the material.

Stress Corrosion Cracking

One of the most serious metallurgical problems and one that is a major concern in the nuclear industry is stress-corrosion cracking (SCC). Stress-corrosion cracking results from the combined action of an applied tensile stress and a corrosive environment, both influences are necessary.

Hydrogen Embrittlement

Hydrogen embrittlement is one of many forms of stress-corrosion cracking. Hydrogen embrittlement results from the combined action of an applied tensile stress and a corrosive hydrogen environment, both influences are necessary.

What is brittle material?

A brittle material is also known as a material having low ductility. A stress-strain curve for brittle and ductile materials is shown in the figure below. We will talk more about ductile materials in the next section.

Why are ceramics so brittle?

In metals, their metallic bonds allow the atoms to slide past each other easily. In ceramics, due to their ionic bonds, there is a resistance to the sliding.

Fracture of Material

Ductile–Brittle Transition Temperature

- As was written, the distinction between brittleness and ductility isn’t readily apparent, especially because both ductility and brittle behavior are dependent not only on the material in question but also on the temperature (ductile-brittle transition) of the material. The effect of temperature on the nature of the fracture is of considerable importance. Many steels exhibit ductile fracture at e…

Stress Corrosion Cracking

- One of the most serious metallurgical problems and one that is a major concern in the nuclear industry is stress-corrosion cracking (SCC). Stress-corrosion cracking results from the combined action of an applied tensile stress and a corrosive environment, both influences are necessary. SCC is a type of intergranular attack corrosion that occurs at the grain boundaries under tensile …

Hydrogen Embrittlement

- Hydrogen embrittlement is one of many forms of stress-corrosion cracking. Hydrogen embrittlement results from the combined action of an applied tensile stress and a corrosive hydrogen environment, both influences are necessary. In this case the corrosive agent is hydrogen in its atomic form (H as opposed to the molecular form, H2), which diffuses interstitially throug…