What shielding gas should I use when welding aluminum?

These gases are used as pure argon, pure helium and various mixtures of both argon and helium. Excellent welds are often produced using pure argon as a shielding gas. Pure argon is the most popular shielding gas and is often used for both gas metal arc and gas tungsten arc welding of aluminum.

What is the best method to use for welding aluminum?

Weld the Aluminum

- Use the push technique when welding aluminum. ...

- Use hotter settings in terms of amperage and voltage. ...

- Pick welding wire that has a melting point similar to the base material that you’re working with. ...

- Choose a welding tip about 0.020 inches larger than the diameter of the filler metal that you’re going to use.

What gas should I use to weld aluminium rods?

- Everyone wants to use aluminum welding rod on applications that the original part failed and is seldom “stronger”. ...

- If your “welding” fail, and you call TIG welder, he will have to grind the alloy completely to clean aluminum with a mill or carbide burr.

- Advertising says you can use any type of torch, in most cases propane one. ...

Which is the best shielding gas for MIG welding?

Shielding Gas for Different Material

- Gas for MIG Welding Aluminum. Pure argon is most commonly used for welding aluminum. ...

- MIG Welding Gas for Steel. When welding mild steel, pure carbon dioxide is the most commonly used gas. ...

- Shielding Gas for Stainless Steel. When welding stainless steel, a tri-mix of helium, argon, and carbon dioxide is often used. ...

Can you use 75 argon 25 CO2 to weld aluminum?

But more seriously,what usually is called 75/25 is 25% Argon and 75% CO2. CO2 is very reactive to aluminum and you'll have a mess. Now if you mean 25% argon and 75% helium (or vice versa), both are inert gases and the mix will work for aluminum.

What gas can be used to weld aluminum and MIG weld?

The two gases used for MIG welding aluminum are argon or helium. They can be used in their pure form, or as a mixture of both. Typically, pure argon is the most popular of these gases to use as a shielding gas in MIG welding aluminum. Pure argon is commonly used up to a sheet thickness of approximately 12.5mm.

Is MIG or TIG better for welding aluminum?

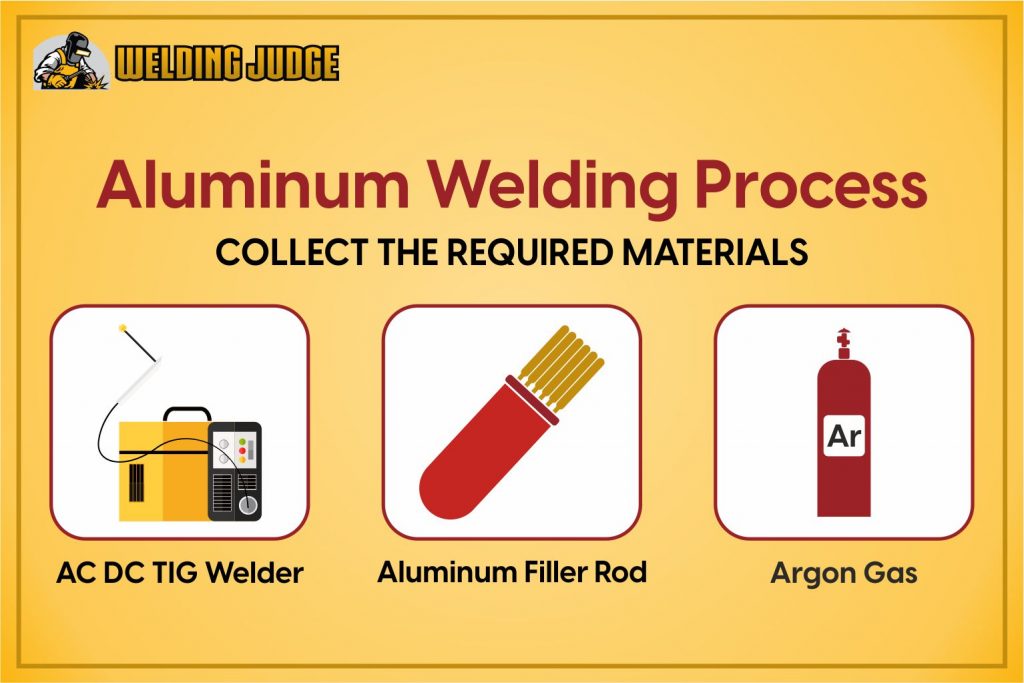

Generally, two processes are used for aluminum welding: GTAW (TIG) and GMAW (MIG). Most welders in the business will say TIG is the better option for welding aluminum because it allows for better results on lighter gauge materials. When done correctly, TIG welding aluminum can produce quality welds.

Can you use nitrogen to weld aluminum?

The following shielding gas suggestions can enable better welding of aluminum: Consider using nitrogen instead of helium in your shielding gas mixes when welding aluminum. Gas purity should be maintained to AWS standards; a shielding gas product with less than 3 PPM of moisture and 5 PPM of O2 content is recommended.

How much is a tank of argon?

Argon gas cylinders are considered the most expensive, with prices going up to $350 for a new cylinder. This is due to the cost of mining and collecting the gas. Buying one large cylinder is more economical than exchanging several small ones.

What is the best way to weld aluminum?

Electron beam welding has a very precise heat affected zone that can be easily controlled, which makes it great for aluminum. Laser beam welding is great for fast, clean welds and is ideal for materials sensitive to cracking, such as aluminum.

How many amps does it take to weld aluminum?

A common rule of thumb is that you will need 1 amp for every 0.001 inches of metal you are going to weld when other variables are constant. That means if you want to weld 1/8-inch aluminum, you will need around 125 amps when other factors are constant.

How do you weld aluminum cheaply?

1:5010:55Amazon's CHEAP Alternative To Aluminum Welding!!! (Alumaloy)YouTubeStart of suggested clipEnd of suggested clipI always use stainless with aluminum a striker if you don't have something that strikesMoreI always use stainless with aluminum a striker if you don't have something that strikes automatically. This is the main torch that I use but I do have three different torches.

Can a Harbor Freight welder weld aluminum?

0:137:43Alumiweld rods from Harbor Freight! Do they work? Can you easily weld ...YouTubeStart of suggested clipEnd of suggested clipThey're basically trying to tell you that with these style of rods and a little bit of heat from aMoreThey're basically trying to tell you that with these style of rods and a little bit of heat from a propane torch that you can weld two pieces of aluminum.

What is the best shielding gas for aluminum?

Pure argonPure argon is the most popular shielding gas and is often used for both gas metal arc and gas tungsten arc welding of aluminum. Mixtures of argon and helium are probably the next common, and pure helium is generally only used for some specialized GTAW applications.

Can you oxy acetylene weld aluminum?

Metal which can be welded with oxy-acetylene flame include iron, steel, cast iron, copper, brass, aluminum, bronze as well as many alloys may be welded. The oxy-acetylene flame is also used for cutting metal, case hardening and annealing.

Can you weld aluminum with helium?

A - There are two shielding gases commonly used for arc welding aluminum, and these are argon and helium. These gases are used as pure argon, pure helium and various mixtures of both argon and helium. Excellent welds are often produced using pure argon as a shielding gas.

Can you weld aluminum with a MIG welder?

Material thickness: Most reputable MIG machines can be used to weld aluminium down to 3mm thickness. To successfully weld materials thinner than 3mm, it may be neccessary to use specialist MIG or TIG welders with pulse capability. (Note: to TIG weld aluminium, you will need an "AC/DC" machine such as the 202T).

Can you use the same gas for MIG and TIG?

An Argon and Helium mixture can be used in MIG as well as TIG welding.

What shielding gas is used for MIG welding?

The four most common shielding gases used in MIG welding are Argon, Helium, Carbon Dioxide and Oxygen. Each provides unique benefits and drawbacks in any given application.

Can you use pure argon for MIG welding?

Can You MIG Weld Steel Using 100% Argon Gas? It's a question every welder will face at some point, and yes, you can MIG weld steel if all you have is pure Argon.

Inert Shielding Gases

When deciding what is the right shielding gas for welding aluminum, we need first to consider the properties of the available gas options.

What is the Right Shielding Gas for Welding Aluminum : MIG

Although, today, argon is the most often used shielding gas in aluminium production, there are two alternatives in gas metal arc welding (GMAW), or MIG as it is more commonly known as. Welders can either go with 100 per cent argon or an argon/helium blend.

What is the Right Shielding Gas for Welding Aluminum : TIG

TIG welding uses a tungsten electrode to create the arc, which is carried by the welder. The other hand adds filler metal to the weld puddle (except when machine or robotic applications). TIG welding has a number of advantages, including more control over the welding process and a tendency to be very clean.

What is the Right Shielding Gas for Welding Aluminum? Additional Considerations

There are a number of other things to consider when considering what is the Right Shielding Gas for Welding Aluminum. These have to be balance with other welding considerations.

Problems with Etching Zones

When using either aluminium MIG or TIG both processes entail the breaking up the aluminium oxide layer that natively develops on the metal to help in weld penetration. They appear to resemble frosted lines and are located near to the weld on both sides of the joint. They are termed arc etching zones.

Summary: What is the Right Shielding Gas for Welding Aluminum

So, what is the Right Shielding Gas for Welding Aluminum? As we have discussed above it depends on numerous factors. The principle one though is the type of welding process to be used.

What is the best rod for welding?

One of the main steps is finding yourself a proper rod. Usually, a TIG welding rod works fine as it has high purity which makes for quality welds. Keep in mind that flux-cored aluminum welding electrodes can be used as well since they are rich in flux.

What is the best welding rod for hard application?

The 1100 filler rod is a good choice for soft application, particularly if bending or shaping is needed. Contrary, the 4043 filler rod is a good choice for hard application if the base metal is not intended to flex. Choosing the welding rod diameter is a guessing game.

What is aluminum flux?

Aluminum Welding Flux and Welding Safety. The purpose of using flux is to remove the aluminum oxide film and protect the puddle from oxygen. The flux used usually comes in powder form mixed with water to get a thin paste. Before you start welding, you should apply the flux to both the base material and the filler rod.

What is the purpose of flux in gas welding?

Gas welding aluminum with an oxy-fuel torch requires using good flux. The main job of flux is to prevent oxidation in the weld puddle. Additionally, it keeps the weld clean of any contaminants and improves the flow of filler metal.

How to heat aluminum?

Aluminum needs to be preheated before the process commences. However, a fair amount of metals do change color after heat input, but aluminum doesn’t. So here are a few tips that will help you recognize that the material is ready: 1 Rub the end of a wooden stick to the metal. If the stick chars then the proper temperature is achieved. 2 Mark the metals being preheated with some blue carpenter’s chalk. At the proper temperature, the line will turn white. 3 Tap the metal with a hand hammer. If you notice an absence of a ring, then the proper temperature is achieved. 4 Carburize the surface of the metal by sooting it entirely. Then, as you apply heat from the torch, the soot will disappear.

How to clean a weld area?

Use a stainless steel wire brush to clean the weld area and wipe off the surface with a clean rag. Joining material thickness of 1/4″ will require you to bevel the edges for good penetration. Sheep and plate edges in particular have to be well prepared. The edges have the same preparations as the steel.

Does gas welding increase density?

Gas welding aluminum increased weld density. On the other hand, conventional aluminum TIG welds are susceptible to porosity if not done correctly. It is an accident waiting to happen if the weld gets contaminated. Welding aluminum with gas and hydrogen is a process that can easily be learned even by a beginner welder.

What gas is used to weld stainless steel?

Welding of stainless steel is typically done with C2 or 2% Carbon Dioxide and 98% Argon. In some cases there is tri-mix shielding gas containing 90% Helium, 7.5% Argon, and 2.5%Carbon dioxide. Again many welding supply stores carry their own mixture that can improve the weld quality and ease of welding on stainless steel.

What gas is used for MIG welding?

Inert gasses used for MIG welding are Argon and Helium. The term inert means they do not react to anything unlike non inert gasses like oxygen that will cause metal to rust. The gasses used are what shield the weld from the air that causes weld defects such as porisity. Argon Gas Inert Gas.

What is the best amount of carbon dioxide to use for short circuit transfer?

Short Circuit transfer requires either pure Carbon Dioxide or a high percentage of Carbon Dioxide. Globular transfer works best with 75% or more Argon in the mixture. Spray transfer depending on the material is also 75% Argon all the way to pure Argon for metals like aluminum.

What is the most common mixture used to weld carbon steel?

The most widely used mixture is called C25 and that is 25% Carbon Dioxide and 75% Argon gas.

What gas is used to weld arcs?

Oxygen is what causes most weld defects however in small percentages mixed with other gasses it improves the arc characteristics. Argon and Carbon Dioxide can be used by themselves. In some case there is tri-mix shielding gas containing Argon, Carbon dioxide and Helium or Argon, Carbon dioxide and Oxygen.

Which gas has a shallow wide penetration?

Here are the basics: Argon gas has shallow wide penetration and has a very smooth fluid like arc. Helium produces a very hot weld with good weld productivity and mild penetration with a fluid arc. Carbon Dioxide produces a deep narrow penetration with a stiff harsh arc that works well in out of position welding.

Is argon gas inert?

Argon Gas Inert Gas. When Carbon Dioxide or Oxygen is added to the mixture, MIG welding is not technically MIG welding anymore. This is due to the fact that both Carbon Dioxide and Oxygen are not inert gasses. The process then becomes GMAW or Gas Metal Arc Welding. Carbon Dioxide Non Inert Gas.