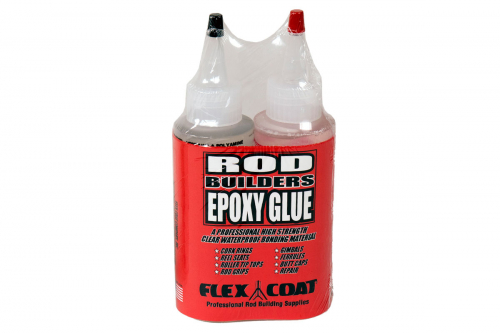

I would not recommend urethane based products like Lumiseal or Permagloss. And stay away from products not designed specifically for rod building. Threadmaster or Flex Coat, both two part epoxies, designed for rod building, will be your best bet.

Full Answer

How do you apply epoxy to a rod?

I pour the epoxy out on this foil and breathe most of the bubbles away. I don't use color preservative but apply the epoxy directly to the threads with 2 different spatulas. The motor turning the rod is a Flex Coat 100-RPM. I have a hand rest 11 inches above the table and next to the rod to steady my hand for application.

Do you carry epoxies for rod building?

We carry epoxies to install arbors, handles and reel seats, or choose a quick cure version for last minute repairs. Choose from a wide variety of fast and tradition curing times, and select the viscosity that is right for your rod building project.

Is there such a thing as perfect thread epoxy finish?

PERFECT THREAD EPOXY - IT'S ROUTINE! Everyone is looking for that perfect, level, smooth glass-like thread finish appearance, and for a method that guarantees such a thing. Well, the good news is that there is such a method, but it won't be exactly the same for each one of us.

How much plywood do I need to build a rod box?

I built the box with one sheet of 3/4-inch plywood. I use an Ingraham model 12-806-timer set for 6 hrs in summer and 8 hours in winter for turning the rods.

What kind of glue is used on fishing rods?

Heat Glue. Heat glue isn't the only type of glue you can use. In fact, you can use epoxy or gorilla glue as well. However, heat glue works well for the simple fact that it's easy to reheat if a mistake is made.

How do you epoxy a fishing rod?

3:1414:03How-To Apply Epoxy To A Fishing Rod | Rod Building 101 - YouTubeYouTubeStart of suggested clipEnd of suggested clipProcess epoxy finish actually has a cure time of about 8 hours until it's dry to the touch. TheMoreProcess epoxy finish actually has a cure time of about 8 hours until it's dry to the touch. The reason it cures. So long is so that it remains flexible. Over its entire life.

How do you put a finish on a rod?

0:005:40Flex Coat Rod Building - Simple Rod Finish Method - YouTubeYouTubeStart of suggested clipEnd of suggested clipYou should start applying the Flex coat finish on the guide foot tip end of the wrap. Starting atMoreYou should start applying the Flex coat finish on the guide foot tip end of the wrap. Starting at this end of the wrap.

How many coats epoxy fly rod?

One thin coat to soak in and seal the threads and behind the guide feet and the second coat makes a nice smooth finish. If you try to make do with one coat and put on too much you'll most probably have a build up of excess epoxy in the middle of the guide wrap which doesn't look too good.

What is 5 minute epoxy used for?

An easy to use, 2-part resin/hardener system for quick repairs, tooling and general bonding. May be used in spot applications to hold parts in position while standard epoxy bonds cure. Bonds to wood, fiberglass, and metal.

How do you clear coat a fishing rod?

0:000:18Polyurethane Clear Gloss Rod Blank Finish: Mud Hole Exclusive LookYouTubeStart of suggested clipEnd of suggested clipWe got our custom rod butters fast-drying polyurethane right here great product self-leveling simpleMoreWe got our custom rod butters fast-drying polyurethane right here great product self-leveling simple to use spray. On your blank. Let it dry about 15 minutes you're all set.

What is the best varnish for fishing rods?

Epoxy Varnish. Epoxy resin makes great glue, is used in composite structures, and can be used as a varnish. The formulations for these are different, so make sure you varnish with epoxy designed as a varnish.

How long does it take for Flex coat to cure?

We allow 24 hours for the primer coat to dry (6 to 8 hours for un-thinned coats) before applying additional coats. We never thin any additional coats after the primer coat.

How do you varnish a rod?

0:4818:42Rod Building: Understanding color preserver, varnishing wraps, and finalYouTubeStart of suggested clipEnd of suggested clipYou want spar varnish full-strength is fine to start off with and we'll talk about cutting it aMoreYou want spar varnish full-strength is fine to start off with and we'll talk about cutting it a little bit later and then some sort of color preserver.

How many coats epoxy fishing rod?

fishonjon said: 1 coat The nice thing about multiple layers is you can remove layer 2 and 3 easily.

How do you mix epoxy Flex Coat?

0:455:13Flex Coat Rod Building - Mixing and Applying Epoxy Glues "How We Do It"YouTubeStart of suggested clipEnd of suggested clipI'm gonna use five minute epoxy for this grip. Because I just can't get all this done in a couple ofMoreI'm gonna use five minute epoxy for this grip. Because I just can't get all this done in a couple of minutes I squirted out two equal diameter but separate pools of epoxy. A little bit bigger than a

How do you thin out a Flex Coat?

Use a stiff brush which will spread the Flex Coat evenly and thinly over the wrap. Heating will also thin the finish. Thinning with a solvent such as acetone or epoxy thinner also works. Between 1 and 4 drops of solvent per 6cc mix of epoxy is recommended.

What is epoxy finish?

Epoxy finish is the key ingredient to crystal-clear thread wraps in custom rod building. But from the thread and epoxy, to the application, curing time and preservation, there many helpful methods in this blog that you need to ensure your final finish has the perfect appearance!

Can you mix epoxy with resin?

When it comes to mixing epoxy, the wrong technique can interfere in the curing process and the epoxy’s resulting appearance. Some rod builders tend to whip the hardener and resin together, but this won’t speed up the process and rather, will add more bothersome bubbles in the mixture.

Do you need to double check epoxy finish?

Once you have applied epoxy to your thread wraps, the epoxy finish is now in its earliest and most important curing stages. Therefore, double-checking the finish is one of the most pivotal parts of the epoxy’s curing process.

Do you double check epoxy?

Once you’re done applying epoxy, not only does double-checking help get a high-quality finish, but also additional protection is available to keep your finishing rod safe and secure from outside influence.

How to get rid of bubbles in epoxy rod?

Start by stirring the mixture slowly and rotating from clockwise to counterclockwise every few turns. This should work to fold and churn the two parts together while also removing the air bubbles.

What are the problems with epoxy?

The most common epoxy problems range from mixing mistakes and application errors, to inconsistent curing times. Since these simple epoxy problems can grow into some huge headaches, it is best to use the following information to ensure your experience is as smooth as the finished epoxy itself.

Why use aluminum dish for epoxy?

Using an aluminum dish helps preserve the epoxy and reduce the number of air bubbles within the mixture. Check out the benefits of ProKote Rod Building Thread Finish to see what it can do for your custom fishing rods.

What is the ratio of epoxies?

Popular epoxies often consist of two parts, one is a resin and the other is a hardener. These two only work in a 50/50 ratio, so it must be combined both accurately and thoroughly to avoid any curing complications.