The Cap Sheet is the layer that goes on top of the base sheet and it covers and protects the layers below it, helping to extend the life of the roof and avoiding leaks. A cap sheet is created from several layers of materials including asphalt

Asphalt

Asphalt, also known as bitumen is a sticky, black and highly viscous liquid or semi-solid form of petroleum. It may be found in natural deposits or may be a refined product; it is a substance classed as a pitch. Until the 20th century, the term asphaltum was also used. The word is derived fr…

What is a cap sheet roof?

- Galvanized roofing sheet: costs from $150 to $350

- Aluminum roofing sheet: costs from $150 to $600

- Zinc roofing sheet: costs from $600 to $1,000

- Polycarbonate: costs from $0.90 to $1.65

- PVC roofing sheet: costs from $4.00 to $7.00 with installation. ...

- Fiberglass roof sheet: cost from $2 to $4 with installation.

What is SBS cap sheet?

What is SBS cap sheet? LIBERTY™ SBS Self-Adhering Cap Sheet. A durable, modified bitumen membrane designed for use as a waterproofing membrane and reinforced with a polyester mat, which is coated with a polymer-modified asphalt. Read rest of the answer. Likewise, what is a cap sheet?

What is a TPO roofing sheet?

- Installation of a TPO Roofing System. TPO roofing is installed in a single membrane application without multiple layers. ...

- TPO Roofing Costs. ...

- Working With a Louisville Roofing Contractor. ...

What is sheet roofing?

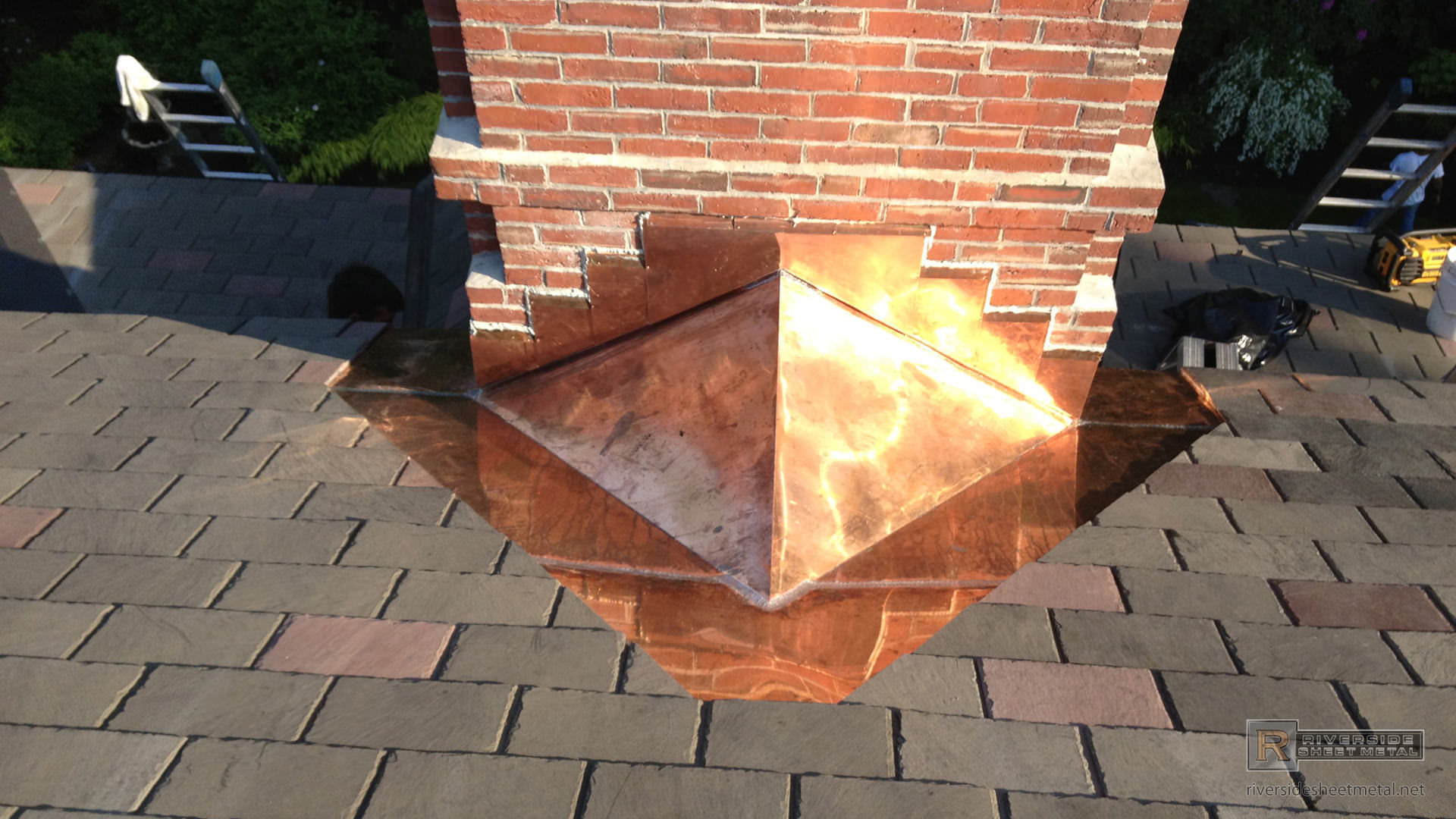

- It is also the most durable, making it a good option in a variety of climates.

- Copper does not need to be coated and is therefore left to age to a natural patina.

- Copper is available in modular and standing seam panel options. Depending on the climate, copper can last up to 200 years when properly installed.

What does sheet cap mean?

Cap-sheet definition Filters. A sheet, often granule-surfaced, used as the top ply of some roof membranes and/or flashings. noun.

How do you use a cap sheet roof?

0:001:20Low-Slope Roof Self-Adhered Cap Sheet Installation - YouTubeYouTubeStart of suggested clipEnd of suggested clipPosition the cap sheet flat and align it with the leading edge of the roof. Once the sheet is inMorePosition the cap sheet flat and align it with the leading edge of the roof. Once the sheet is in position remove the first of the two split release films.

What is a base and cap roof?

Base and cap sheets are a form of sbs rubber or modified bitumen, using a self adhering sheet to create a roofing system for a low slope roof.

What is a cap sheet flat roof?

Torch applied roofing is a flat roof covering solution that involves three layers of modified bitumen (felt) melt-welded onto the roof surface and each other with the use of a blowtorch to create an impenetrable, waterproof seal.

Are cap sheets waterproof?

The cap sheet is used to provide a watertight surface and protection and is one of the most important components of a building providing protection and comfort to its occupants.

How long does a cap sheet roof last?

In general, a properly installed built-up roofing system will last 20 to 30 years.

How do you cut a cap sheet?

0:071:07Low-Slope Self-Adhered Cap Sheet Flashing Outside Corner Detail ...YouTubeStart of suggested clipEnd of suggested clipUse a knife with a hook blade to make the first relief cut make the cut in an upward angle and roundMoreUse a knife with a hook blade to make the first relief cut make the cut in an upward angle and round out the edges.

What is cap sheet membrane?

SA-SBS Cap Sheet membranes are specially designed for applications where the use of hot asphalt, cold process adhesive, or a propane torch is undesirable. Applications include new roofing, recover (retrofit) and BUR repairs.

What is TPO roofing?

Thermoplastic Polyolefin is a single-ply roofing membrane that is one of the fastest-growing commercial roofing systems on the market. TPO roofing systems are made up of a single layer of synthetics and reinforcing scrim that can be used to cover flat roofs.

What is EPDM roofing?

EPDM is an extremely durable synthetic rubber roofing membrane that is used worldwide. EPDM is available in both black and white and is sold in a variety of widths and thicknesses.

What is granulated cap sheet?

The cap sheets are surfaced with a bright-white, highly reflective granule that's both durable and energy efficient. The granule mitigates solar heat and provides additional comfort to the interiors of the buildings it protects.

What is modified bitumen cap sheet?

Used in low slope roofing such as built-up roofing (BUR) or modified bitumen roofing, a cap sheet is used to create a water-tight surface. Constant exposure to wind and weather can cause a BUR roof to become brittle and crack, then water can seep into the cracks, eventually working into the interior of the building.

How many sheets are needed for a low slope roof?

A low-slope roof will be covered with a minimum of two sheets: a base sheet and a cap sheet. The base sheet provides waterproofing and a top surface that can bond with the cap sheet. The cap sheet provides colour, protection from fire, ultraviolet (UV) radiation protection and resistance to mechanical abuse. The base sheet and cap sheet must be ...

What is ARMA roofing?

The Asphalt Roofing Manufacturers Association (ARMA) is an excellent resource with a number of educational articles regarding the proper installation of roofing products. IKO is an active member of ARMA and encourages you to read “ Choosing the Right Installation Method for Your Low-Slope Asphalt Roofing System .”

What is a BUR base sheet?

While these systems only have one base sheet, they will have multiple components. The base sheet in a BUR system can be made of felt, fiberglass or polyester.

What is a fiberglass base sheet made of?

It is made of fiberglass or reinforced polyester, or composite reinforcement and is saturated/coated with modified bitumen asphalt. This is asphalt enhanced with plastic or rubber polymer. Base sheets are surfaced with heat-weldable film, sand or a release film depending on the application requirements.

Can Iko base sheets be used with asphalt?

Base sheets in BUR systems can be impregnated with unmodified asphalt, or they may be impregnated with modified bitumen, a high-performance asphalt. IKO can provide guidelines for you to choose which base sheet is best for your application depending on the expected life of the roof.

How many sheets are needed for a low slope roof?

A low-slope roof will be covered with a minimum of two sheets: a base sheet and a cap sheet. The base sheet provides waterproofing and a top surface that can bond with the cap sheet. The cap sheet provides colour, protection from fire, ultraviolet (UV) radiation protection and resistance to mechanical abuse. The base sheet and cap sheet must be ...

What is a low slope roof made of?

It is made of fiberglass or reinforced polyester, or composite reinforcement and is saturated/coated with modified bitumen asphalt. This is asphalt enhanced with plastic or rubber polymer. Base sheets are surfaced with heat-weldable film, sand or a release film depending on the application requirements. A low-slope roof will be covered ...

What is ARMA roofing?

The Asphalt Roofing Manufacturers Association (ARMA) is an excellent resource with a number of educational articles regarding the proper installation of roofing products. IKO is an active member of ARMA and encourages you to read “ Choosing the Right Installation Method for Your Low-Slope Asphalt Roofing System .”

What is an overlay board?

Overlay cover board: Cover boards are components that can add hail and other mechanical resistance to a well-engineered roofing system. Base sheet: Your deck type needs to be considered when selecting a base sheet. For example, a lightweight concrete or nailable deck may need a venting base sheet.

Can Iko base sheets be used with asphalt?

Base sheets in BUR systems can be impregnated with unmodified asphalt, or they may be impregnated with modified bitumen, a high-performance asphalt. IKO can provide guidelines for you to choose which base sheet is best for your application depending on the expected life of the roof.

What are the different types of roofing sheets?

Today, let us talk about the different types of roofing sheets. Know what to expect and see what options you have. 1. Corrugated. From the word corrugated, this type of roofing sheet has repetitive folds. The corrugation that it forms intensifies the roof’s integrity.

Why are roofing sheets installed?

Different types of roofing sheets shield the actual roof from external elements. When mounted correctly, it helps prevent leaks and potential damages to prolong your roof’s lifespan.

What is the least durable roofing material?

Plastic. Plastic roofing sheet may be the least durable among the choices you have but it has its own advantages. Most people use the plastic material for smaller structures and for temporary constructions. Its durability is dependent on the type of plastic that you will use for the roofing sheet.

What is the best roofing material for commercial buildings?

Polycarbonate. These types of roofing sheets are often used in large commercial and industrial buildings due to its promising performance. Polycarbonate is fire-resistant. Although it is more durable than other roofing materials, they have the tendency to crack.

What is metal roofing made of?

Metal roofing sheets have a protective layer made up of zinc. Then, they are reinforced with another layer of chromatic acid that prevents rusting. Characterized by superior roof coverage, they are mostly used for garages, backyard sheds, garden buildings, household cladding, industrial roofing, and many more.

What are the advantages of polycarbonate roofs?

Another advantage of polycarbonate is that it could act as an insulator reducing the heat that passes through the roof. Property owners can choose from a wide variety of special finishes like UV protection, corrosive inhibitors, and anti-static. Apart from this, there is also a variety of customizable colors available.

Is corrugated roofing waterproof?

Corrugated roofing sheet made from bitumen is waterproof. It is long-lasting and highly durable. 2. Sheet Metal. Sheet metal roofing sheets are similar to the corrugated ones in terms of composition. However, they have significantly fewer curves manufactured from metals like stainless steel or aluminum.