Refractory

Refractory

A refractory material is one that retains its strength at high temperatures. ASTM C71 defines refractories as "non-metallic materials having those chemical and physical properties that make them applicable for structures, or as components of systems, that are exposed to environments ab…

What is refractory mortar and where should it be used?

Refractory mortar is a specially engineered mixture of sand, calcium aluminate, cement, and fireclay. It is used to lay firebrick in places that are exposed to extremely high temperature. The refractory mortar is utilized only to build fire places and shall not be applied on hot faces.

How to mix refractory mortar by hand?

Type N

- Portland cement—3.375 cu ft

- Hydrated lime—3.375 cu ft

- Sand 20.25—cu ft

Where to buy refractory?

The manufacturers of refractory materials are producing and selling all kinds of refractories, for the different thermal equipment and furnaces used. As one of the supplier of Refractory Cement 3000 degree, RS Refractory Company provides you much more selection for buying refractory castable cements.

What does it mean to be refractory?

The refractory period is the span of time after having an orgasm during which a person is not sexually responsive. The refractory period can have both mental and physiological effects. During the refractory period, a person might lose interest in sex, or they might not be able to have sex.

How do you make refractory mortar?

0:000:51Refractory Mortar - High Temp Mortar - Homemade Mortar - YouTubeYouTubeStart of suggested clipEnd of suggested clipUse one part Portland cement one part fire clay one part hydrated lime and three parts silica sandMoreUse one part Portland cement one part fire clay one part hydrated lime and three parts silica sand mix the dry ingredients together first prior to adding approximately 1.5. Parts of water.

What is the composition of refractory cement?

A composition of refractory cement includes about 65 percent by weight of refractory clay, about 15 percent by weight of ball clay and about 20 percent by weight of calcium aluminate cement to yield a product composition which is air-setting, acid resistant, and non water soluble.

What's the difference between refractory mortar and refractory cement?

So refractory mud is a kind of binder, but refractory mortar belongs to refractory cement, refractory cement can do binder can also do refractory concrete pouring use.

What is refractory mortar?

What is refractory mortar? Hydraulic refractory mortar is a specially-engineered blend of specific cements and aggregates that gives the mortar unique heat-resistance and thermal characteristics for use in high-temperature applications such as chimneys, fire pits, barbeques, and pizza ovens.

Which mineral is used as refractory material?

Periclase (MgO, M.P. 2825°C) is the most important refractory mineral in the metals industry. It can be found in the following refractories: magnesia, chrome-magnesia, forsterite -magnesia, spinel -magnesia, and dead-burned dolomite.

What cement would you use for refractory purposes?

Refractory high alumina cement is made by grinding alumina and calcareous material such as lime through sintering or fusing. Also known as calcium aluminum cement, it is a common and popular refractory material because of its benefits and uses.

Can you mix refractory cement with regular cement?

Never use a cement mixer. Refractory mixed in a cement mixer will not have the strength characteristics expected by design. A cement mixer should only be used for adding the initial amounts of water to the dry mix.

Is fire cement the same as refractory cement?

Refractory mortar is a mix of cement, sand, fireclay and, other specialized ingredients such as calcium aluminate. Fireclay is a set of various clays that can resist heat up to 3,000 degrees Fahrenheit. Just think of this as clay that has special heat resistant properties.

What mortar do I use with fire bricks?

The mortar in most brick joints consists of sand, lime, and portland cement. But in a fireplace, that mix just crumbles away when subjected to roaring wood fires. For this application, masons rely on a refractory mortar made of magnesium silicate, which can withstand heat up to 2,000 degrees F.

What is the best refractory mortar?

Hydraulic-setting Mortar It is also called non-water-soluble refractory mortar and considered the best available refractory mortar.

Is refractory cement toxic?

General: No other known significant effects or critical hazards. Carcinogenicity: Crystalline silica - long term overexposure may cause permanent and irreversible lung damage, including silicosis, and increase the risk of lung cancer, kidney, and liver damage.

Can I use regular mortar for fireplace?

Domestic Fireplace Mortar is a premixed and ready to use regular mortar. It was developed for installation of firebrick in masonry fireplace installations. It also has many other uses such as in chimneys, boilers, incinerators, furnaces, kilns, etc.

How do you make fire resistant mortar?

There are a few different methods, but the most common is to mix in sand or other small particles into the mortar.

How do you make refractory cement at home?

You can make refractory cement at home by mixing together a mixture of sand, clay, and Portland cement.

What is refractory mortar made of?

Refractory mortar is a type of ceramic material used in masonry and bricklaying. It is made by mixing clay with sand, gravel, and water.

Is it possible to produce refractory cement?

Refractory or heat resistant concrete may be prepared using heat resistant cement or bought as a ready-to-mix product in bags. Castable is a term used to describe the packed one. However, even if it is refractory, it is not easy to cast big hot face section/s out of it.

What is the best way to create refractory?

Using the aforementioned measurements, combine Perlite and Fire Cement.

Is it possible for me to manufacture my own fire bricks?

You may use a piece of plastic sheeting to cover a flat surface or mix the refractory cement on a smooth concrete surface. Pour one-half part masonry cement, one-half part perlite, two parts fire-clay, and two parts sand into the mold. Using a shovel, stir the dry ingredients until it is completely combined.

What is the process of making refractory brick?

Kiln bricks are produced by partially vitrifying a clay-based composition in a kiln, and they may also be glazed for specific reasons. The main raw material in refractory bricks is typically chamotted with other materials and contains 30-40% alumina.

What is the best way to make refractory cement?

Using a gentle mist of water, dampen the work surface. Cast it in place and pat it down to eliminate any air pockets, but don’t smooth it out to a slick finish since this will prevent water from escaping. The form or mold must be waterproof to prevent the mixture from absorbing water, which is required for the hardening process.

What is the function of refractory cement?

Refractory cement is used in the construction of brick or stone fireplaces, grills, and other high-heat structures. Instead of Portland cement, refractory cement utilizes a chemical called calcium aluminate as a cementing agent in the mix.

How long does it take for refractory mortar to dry?

The beginning setting time of refractory cement should not be less than 45 minutes, and the ultimate setting time should not be more than 390 minutes, under typical conditions. After the refractory cement has set, the refractory mortar should be allowed to dry.

How thick should refractory mortar be?

Practical Tips for Refractory Mortar 1 Generally, maximum thickness of refractory mortar in high quality oven is 6 mm. 2 If mortar thickness is greater than 6 mm, it shrinks and left space between bricks and eventually allow bricks to move. 3 Mortar thickness greater than 6mm is allowed for locations away from the hot face. 4 Refractory mortar shall be used only for the brick structure to stay strong and stable. It shall not be left exposed on the hot-face. 5 Refractory mortar is not applicable for filling holes or big spaces or gaps between firebricks. 6 Use recommendation of applicable code to specify number of days between the end of construction and exposing the mortar to high temperature.

Why is air drying mortar used?

It is used in the construction of kilns and furnaces. Finally, it sets quickly after laying and can be clean easily since it dissolves in water. 3.

What is hydraulic setting mortar?

Hydraulic-setting mortar is a mixer of aggregate and binder and withstand temperature of 1499C for a minimum of 6 hours.

Does mortar dissolve in water?

The properties of such mortar are inferior to hydraulic setting mortar. For instance, it dissolves in water after drying and require long time to dry in wet environment. Added to that, premixed or air-dry mortar may cause efflorescence.

Can refractory mortar be left on hot face?

Refractory mortar shall be used only for the brick structure to stay strong and stable. It shall not be left exposed on the hot-face. Refractory mortar is not applicable for filling holes or big spaces or gaps between firebricks.

Is hydraulic setting mortar the same as Portland based mortar?

The hydraulic setting mortar is similar to Portland based mortar in terms of workability and curing. Moreover, It is easier to ship and store than premixed. This type of refractory mortar comes dry in bags and is not subject to separation, hardening, or freezing before it is used.

Why does refractory cement fail?

While regular cement may expand well in conjunction with other rigid equipment, it often fails upon contraction due to the deterioration of clinker or binding material. Refractory cement uses binding materials with improved thermodynamic properties to reduce the risk of mechanical failure.

What is high temperature masonry?

High-temperature masonry comes in multiple forms, from thermodynamically stable firebricks to castable refractory cement that are formulated from thermally resistant clinker and specialized aggregate materials. Conventional cements are often used in the manufacturing of fireplaces and furnaces, but they do not exhibit the requisite thermodynamic ...

What is cement used for?

Conventional cements are often used in the manufacturing of fireplaces and furnaces, but they do not exhibit the requisite thermodynamic stability for application within the heating chamber or for direct application to components that will experience significant thermal stress.

What is the purpose of a cement?

Cements used to adhere structural metals together in refractory applications, or for the sealing of gaskets and joists, must retain their structural integrity in the presence of continuous thermodynamic stress.

So What Is The Difference Between Cement, Concrete, and Mortar?

Why Not Just Use Concrete Instead of Mortar?

- The answer lies in a couple of areas. If you bond a block or brick wall with mortar and that wall settles naturally, the easiest link will give, in this case, it would be the mortar. If you had concrete in between all of the blocks, your block may crack and give instead of the weaker mortar. Since you can not prevent settling, the best idea is to ensure the damage from settling is minimal. Rep…

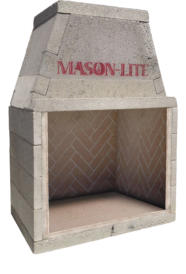

Where Should Refractory Mortar Be used?

- It took us a minute to get here, but here we are at last. I’ll provide two answers, a logical one and then a dictated one. Logically, refractory mortar should be used anywhere where it will be exposed to very high temperatures. This is common sense, and yet we repeatedly see failures in certain parts of the chimney and fireplace fireboxes because a mason did not use the proper type of mo…

Does Everyone Use Refractory Mortar Where They Should?

- Sadly, no. It is so easy for a mason who has prepped a bunch of mortar to just use the same mortar for everything and ignore the NFPA recommendation. Also, some masons are in the habit of mixing up their own batches of fireclay infused mortar, but these on the job mixes are not tested and often do not protect against the extremely high heat that is produced by a fireplace. …