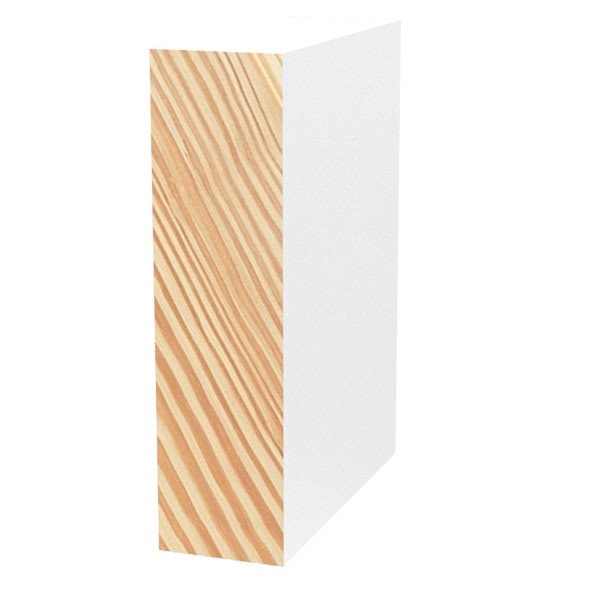

Primed Finger-Joint Pine Board are: fascia, corner boards, trim base molding, furniture parts, shelving, cabinets, etc. It is primed for your convenience and therefore ready to paint. This Radiata Pine finger joint primed board can be used for interior and exterior uses, separating it from many other products.

What is primed FJ pine?

Primed FJ Pine is pre-coated with two coats of a specially developed water-based primer. It is manufactured from FJ Clear Pine which provides enhanced strength & stability and finger jointed glue-bonds offers longer lengths. Pre-coated primed finish appears matte white.

What is primed finish?

Primed finish imparts high tolerance to cracks and scratches. How much will you need? Please note: calculations are estimates and can only be made using whole numbers. Clear Finger Joint Primed Pine is a perfect product for many uses, especially for painting.

What is the primed process?

The primed process includes pre-sanding, a first coat, sanding and a second coat. The final finish is ready for most applications of a top coat providing a substantial time and cost savings.

How do you finish Porta primed FJ pine?

Porta Primed FJ Pine is prepared to be ready to finish with a top coat of acrylic or solvent based coating. It is good practice to fill any nail holes or marks first. Lightly sand with 600 grade aluminium oxide paper and wipe down.

What does FJ mean in timber?

FJ. Finger Jointed timber comprises lengths of timber joined end to end, utilising a micro-sized finger (joint) employing an adheshive whose strength and potential overall length is increased through glue bonds.

What is primed FJ pine?

Primed FJ Pine is pre-coated with two coats of a specially developed water-based primer. It is manufactured from FJ Clear Pine which provides enhanced strength & stability and finger jointed glue-bonds offers longer lengths.

What is FJ wood?

Finger Joint is believed to have begun with wooden produce boxes or crates in the days before modern, man-made materials. Finger Joint Boards are long tapered fingers that interlock to join two pieces lengthwise as in commercial moulding or side by side, in panels.

What is FJ trim?

(substitute for quarter round) Made from finger-jointed pine to be more water resistant than MDF. ... This profile is thicker and lower than our Elite shoe trim which we custom made specify for our wainscot kits. This trim is also used as a door stop.

Can you use primed FJ pine outside?

Finger Jointed Treated Pine Primed products are suitable for all above ground exterior applications. ... Allow the preservative to dry and then apply a premium quality alkyd based primer or quality solvent alkyd (oil) based primer before being fixed into position.01-May-2014

Is primed pine wood?

3/4″ Primed Pine Boards Boards are made of finger-jointed clear Radiata Pine with an exterior grade primer. These boards can be used interior or exterior. These boards are often used for exterior trim, fascia, bookshelves, shelving and furniture.

What are the disadvantages of a finger joint?

Finger Joint ConsCan come out crooked.Harder to achieve a smooth wall.28-Nov-2018

Can you stain finger jointed wood?

Staining Finger Joint Pine Being a natural material, finger joint pine can be stained instead of primed and painted if having an exposed wood grain appeals to you.31-Mar-2021

Are finger joints strong?

What are Finger Joints? In woodwork and manufacturing, a finger joint is also known as a comb or box joint. This is when two pieces of wood are joined together and glued. ... This joint is strong and needs no extra support especially when used with good quality glue such as PVC.27-Nov-2018

What is primed MDF wood?

MDF is medium density fiberboard and usually made offshore. ... MDF has zero imperfections. It is always primed and ready for paint. MDF and has zero warps or twists in the material.20-Jun-2019

What is finger jointed pine?

The jointed pine is composed of pieces of pine glued end to end or side by side (laminated). This product is very popular when looking for a very stable pine because the risk of warping is almost none when using this type of product.

What is the difference between finger joint base and MDF base?

Although MDF is stronger, it is more difficult to repair if dents or marks are made on the material. Finger jointed pine is slightly more expensive than MDF. As it is a natural timber material, it is softer than MDF and can be more susceptible to marks. Intrim ran a test to show the effect of moisture on MDF.11-Nov-2018

Why is finger joint lumber so cheap?

Finger joint lumber is cheap because the manufacturers can use small lengths of leftover wood to assemble full length of moldings.

How to make a piece of wood extend to almost any length?

It’s a great way to make a piece of wood extend to almost any length by adding more and more pieces to the end. The finger joint is then glued with a wood glue or other adhesive and clamped together to cure.

Is finger joint lumber good for molding?

While it can save you a lot on your lumber and molding costs it may not be the best choice for your project. Finger joint lumber was the lumber industry’s way of creating the long pieces of wood that we need for non-structural things like trim and casings.

How much will you need?

Please note: calculations are estimates and can only be made using whole numbers.

Product Overview

Clear Finger Joint Primed Pine is a perfect product for many uses, especially for painting. Uses include fascia, corner boards, trim base molding, furniture parts, shelving, and cabinets. There are no knots to bleed through your final top coat of paint, making it a great product for painting.