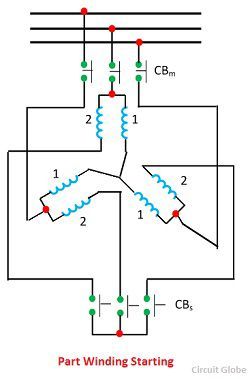

Motors designed for “part winding start” utilize only a portion of the winding at start-up. This meansa portion of the windings are energized with full load voltage. Since the windings are divided intotwo parallel circuits, the motor will only be exposed to a portion of the current at start-up dependingon the design.

What is a part winding motor starter?

'' Part-winding starters are used with motors having two separate and parallel windings in the stator, connected either wye or delta. This type of starting does not necessarily reduce the starting current but rather starts the motor incrementally, thereby splitting the inrush current in sections.

What are the advantages of a part winding start?

couple of advantages of using part winding start is to minimize voltage drop in a facility andexcessive heat during start-ups.

When does the starter change the motor coils from Wye to Delta?

After a predetermined time, the starter changes the motor coils from wye to delta, which is the full voltage running connection. Note that in the following figure one of the "S" contactors is shown dotted since some starter manufacturers use only two instead of three contactors.

What is a star delta starter used for?

A star delta starter is the most commonly used method for the starting of a 3 phase induction motor. In star delta starting an induction motor is connected in through a star connection throughout the starting period. Then once the motor reaches the required speed, the motor is connected in through a delta connection.

What is part winding method?

This method used only a portion (usually one-half, but sometimes two-thirds) of the motor winding, increasing the impedance seen by the power system. It is to be used only for voltage recovery, and must not be left on the start connection for more than 2 to 3 seconds.

What is winding part in a motor?

0:214:21Part Winding Motor Starter - YouTubeYouTubeStart of suggested clipEnd of suggested clipCurrent when we start a motor to reduce our load on the system and possibly get some smallerMoreCurrent when we start a motor to reduce our load on the system and possibly get some smaller conductors. And maybe reduce some tripping things like that. So with this part winding starter.

What type of starting Do Part winding starter provide?

Another advantage of part winding starters is that they provide closed transition starting, since the motor is never disconnected from the power line during the starting time. Some, but not all, dual voltage motors may be used for part winding starting.

What is meant by part winding starting of an induction motor?

Part winding starting is another method of reducing the starting current of squirrel cage induction motors. Motors designed to be used for part winding starting contain two separate stator windings (FIG. 1). The stator windings may be wye or delta connected, de pending on the manufacturer.

What is the advantage of part winding starting?

Motors that split the winding two thirds to one third energizing two thirds will see a current reduction of 33% at start-up. A couple of advantages of using part winding start is to minimize voltage drop in a facility and excessive heat during start-ups.

What are two types of winding?

The motor winding types are two types which include the following.Stator Winding.Rotor winding.

What is a star delta starter?

Star/Delta starters are probably the most common reduced voltage starters. They are used in an attempt to reduce the start current applied to the motor during start as a means of reducing the disturbances and interference on the electrical supply.

What is a Wye Delta Motor Starter?

A Wye-Delta starter (also known as Start Delta) is one of the most commonly used methods for the starting of a three phase induction motor. In this configuration of starting an induction motor, the motor is started in the Wye configuration (ref fig 1.)

What is the purpose of a wye start and Delta run?

By using the Wye Start/Delta Run method, customers can achieve lower starting current demand when the sprinkler system motor is started in a building that is in distress or experiencing an electrical fire.

What is an across the line starter?

Full-voltage starters, also referred to as across-the-line starters or direct-on-line (DOL) starters, are full-voltage non-reversing (FVNR) and connect the motor to a power line. Manual starters are limited to single-phase motors through about 5 HP at 320 VAC and three-phase through 10 HP at 460 and 575 VAC.

How is a third step gained in part winding starting?

Three-step starting is similar to two-step starting, except that when the first contactor closes, the first winding is connected to the line through a resistor in each phase, ill. 4. After a time delay of approximately 2 seconds, this resistor is shunted out and the first winding is connected to the full voltage.

How does an auto transformer starter work?

Auto transformer Starter Working. Such starters consist of an auto-transformer, with necessary arrangements. At the time of starting, a reduced voltage is applied across the motor through the tappings of the autotransformer. The motor gets a lower starting voltage according to the selection of the tapping.

What is the difference between a star and a delta winding?

In a star/delta motor the star winding is to get the motor to run up to full speed but the Delta winding provides more torque at the motors slip speed.

How many leads are needed for a star delta starter?

A star-delta starter can be used on a motor with only 6 connection leads, a partial winding can ONLY be used on a dual voltage motor with all nine leads (for star connected) or all twelve leads (for delta connected) are available.

Is Direct On Line a starter?

First off, Direct on line isn’t a type of motor, it’s a type of motor starter, or more accurately a motor controller. Similarly, Star delta is another kind of motor controller (starter), not a kind of motor, that allows a high torque three phase AC motor to be started with less torque to prevent damage to the motor and it’s driven load.