What is grinding-wheel loading?

Grinding-wheel loading can be defined as ground material either adhere to abrasive grains or become embedded in voids on a grinding-wheel surface. This phenomenon deteriorates grinding-wheels, and consequently the surface integrity of ground materials, such as surface roughness of the ground materials due to excessive friction and heat.

What is a grinding wheel grade?

The grade refers to the harness or strength with which the bond holds the abrasive grains of a grinding wheel in a place. The Grade is indicated by the English alphabet A to Z. A denotes Sofest and Z denotes Hardest Grade. The different grade of the grinding whee l as follows:

What is the meaning of wheel loading?

In grinding process, this phenomenon is called “(wheel) loading”, which can be defined as the state of a grinding wheel when particles of a work-piece material either adhere to the grits or become embedded in the spaces between abrasive grains on grinding wheels.

How to mount a grinding wheel?

Proper steps in mounting a grinding wheel are as follows: Handle and store grinding wheels in a careful manner. Handle and store all grinding wheels as if they were made of glass! Select the proper grinding wheel and machine for the job. Lock out and tag all machines before working on them.

What is loading and glazing in grinding wheel?

Grinding Chatter. Wheel Loading – Metal Lodged on Grains or in Wheel Pores. Wheel Glazing. Burning of Work.

What is dressing and loading in grinding?

When the sharpness of grinding wheel becomes dull because of glazing and loading, dulled grains and chips are removed (crushed or fallen) with a proper dressing tool to make sharp cutting edges and simultaneously, make recesses for chips by properly extruding to grain cutting edges.

What is the reason for loading defect in grinding wheel?

Common grinding faultsProblemPossible CausesLoading Glazing SheddingPoor cutting ability Wheel glazing Wheel loading Burned work Chatter marksWheel too hardLoadingWheel specification unsitableIncorrect wheel dressingPoor coolant quality6 more rows

What is meant by glazing of a grinding wheel?

Explanation: Glazing: When a surface of the wheel develops a smooth and shining appearance, it is said to be glazed. This indicates that the wheel is blunt, i.e. the abrasive grains are not sharp. Glazing is caused by grinding hard materials on a wheel that has too hard a grade of bond.

What is truing and dressing of grinding wheel?

Dressing removes the clogs on the surface of the wheel and the blunt grains of the abrasive, exposing the new sharp abrasive grains of the wheel which can be cut and brought to shape efficiently. TruingTruing refers to the shaping of the wheel to make it run concentric with the axis.

What is dressing and turning of grinding wheel?

Dressing the wheel refers to removing the current layer of abrasive, so that a fresh and sharp surface is exposed to the work surface. Trueing the wheel makes the grinding surface parallel to the grinding table or other reference plane, so that the entire grinding wheel is even and produces an accurate surface.

What are grinding wheel defects?

Grinding Problems – Causes and CorrectionsGRINDING ISSUECAUSESFine spiral or thread scratches on workFaulty wheel dressingNarrow and deep regular marksWheel too coarseWide irregular marks of varying depthWheel too softWidely spaced spots on workOil spots or glazed areas on wheel face24 more rows

What are the three mechanisms of grinding wheel wear?

Three mechanisms are recognized as the principal causes of wear in grinding wheels: (1) grain fracture, (2) attritious wear, and (3) bond fracture.

What is Wheelwear?

The wheel wear process. Regular wear of railway wheels is the result of the wheel exchanging frictional forces with the rail. Hence, particularly relevant to the formation of regular wear are vehicle running conditions where large frictional forces occur on the wheel: traction, braking and especially curve negotiation.

How do you deglaze a grinding wheel?

0:323:04How to dress a grinding wheel - YouTubeYouTubeStart of suggested clipEnd of suggested clipOn here that rotate. And what they'll be doing is basically knocking against the wheel and chippingMoreOn here that rotate. And what they'll be doing is basically knocking against the wheel and chipping away the grit.

How can you measure grinding wheel wear?

When the compressed air flow is blown onto the working surface of the grinding wheel, the back pressure in the measuring chamber corresponding to the gap between the probe and the working surface of the grinding wheel can be measured. Therefore, the radial wear value of grinding wheel can be determined.

What is grinding wheel loading?

Grinding-wheel loading can be defined as ground material either adhere to abrasive grains or become embedded in voids on a grinding-wheel surface. This phenomenon deteriorates grinding-wheels, and consequently the surface integrity of ground materials, such as surface roughness of the ground materials due to excessive friction and heat. Newly developed cup-type diamond-grinding-wheels with hexagonal pattern were used to grind a magnesium alloy AZ31B in the present work.

What is wheel loading mechanism?

1. The wheel loading mechanism is not related to local positioning of one or two abrasive grains, but related macroscopic positions of several active grains. In other word, the characteristic distance of loading is not order of μm, but in order of mm distance. 2.

What are diamond grinding wheels?

Diamond grinding wheels are newly developed with hexagonal pattern, which contain abrasive diamond grains on hexagon edges and green carborundum porous material without diamond grains in inside of the hexagons [9].

How many grains are in a hexagonal edge?

The edge width of hexagons is 1 mm or 2 mm. Therefore there are about 14 or 30 grains in the hexagon edges in the transverse direction on the grinding surface.

What is the term for the process of grinding a piece of material?

In grinding process, this phenomenon is called “ (wheel) loading”, which can be defined as the state of a grinding wheel when particles of a work-piece material either adhere to the grits or become embedded in the spaces between abrasive grains on grinding wheels.

Why do hexagons have loadings?

If the mechanisms proposed previously would be right, there must be loadings on all edges of hexagons, because there are more than enough diamond grains in all edges. The loading is not caused by one or two grits, but caused by many grits. The loading mechanism proposed here is as the following.

Why do diamond chips not react with diamond grains?

The cold chips or droplets formed by a few chips hit hot diamond grains which are located in the next hexagonal edge along radial direction, can not join to form larger droplets because of low temperature, and do not react with the diamond grains because of low temperature and too small droplet size.

What is a grinding wheel?

Grinding Wheel Definition: Grinding wheels are expendable wheels composing of an abrasive compound . A Grinding wheel having multiple cutting edges made up of many hard a particle called as abrasive s. The abrasives are crushed to have sharp edges for cutting operations.

What is straight grinding wheel?

Straight Grinding wheels: The straight wheel is the most common mode of a wheel that is found on pedestal or bench grinders. This is the one widely used for centreless & cylindrical surface grinding operations. As it is used only on the periphery, it forms a little concave surface on the piece.

What does grit mean in grinding?

Grit or Grain of Grinding wheel: The grit or grain is used to indicate a general size of abrasive for making a grinding wheel. Grits or Grain size is denoted by a number indicates the number of meshes per linear inch of the screen through which the grain pass when they are graded after crushing.

What is a grinding wheel?

A grinding wheel is a wheel composed of an abrasive compound and used for various grinding (abrasive cutting) and abrasive machining operations. Such wheels are used in grinding machines .

What is grinding wheel dressing?

Grinding wheels are self-sharpening to a small degree; for optimal use they may be dressed and trued by the use of wheel or grinding dressers. Dressing the wheel refers to removing the current layer of abrasive, so that a fresh and sharp surface is exposed to the work surface.

What is the difference between a less dense wheel and a less dense wheel?

Density is the ratio of bond and abrasive to air space. A less-dense wheel will cut freely, and has a large effect on surface finish. It is also able to take a deeper or wider cut with less coolant, as the chip clearance on the wheel is greater.

What is a cylindrical wheel?

Cylinder or wheel ring. Cylinder wheels provide a large, wide surface with no center mounting support (hollow). They can be very large, up to 12" in width. They are used only in vertical or horizontal spindle grinders.

Why do wheel cuts release grains of abrasive?

As the wheel cuts, it periodically releases individual grains of abrasive, typically because they grow dull and the increased drag pulls them out of the bond. Fresh grains are exposed in this wear process, which begin the next cycle.

What is a cut off wheel?

Cut off wheels, also known as parting wheels, are self-sharpening wheels that are thin in width and often have radial fibres reinforcing them. They are often used in the construction industry for cutting reinforcement bars (rebar), protruding bolts or anything that needs quick removal or trimming. Most handymen would recognise an angle grinder and the discs they use.

What is a tapered wheel?

Tapered wheel. A straight wheel that tapers outward towards the center of the wheel. This arrangement is stronger than straight wheels and can accept higher lateral loads. Tapered face straight wheel is primarily used for grinding thread, gear teeth ...

What is the proper way to mount a grinding wheel?

The improper mounting of a grinding wheel is a major cause of grinding wheel breakage. Proper steps in mounting a grinding wheel are as follows: Handle and store grinding wheels in a careful manner. Handle and store all grinding wheels as if they were made of glass! Select the proper grinding wheel and machine ...

What to do if your wheel doesn't fit?

If the wheel does not fit, don’t use it. Don’t over-tighten the mounting nut or mounting screws. Tighten flanges just enough to prevent wheel slippage or to machine manufacturer’s recommendation. EXCESSIVE TIGHTENING CAN CAUSE DAMAGE TO THE MOUNTING FLANGES AND WHEEL BREAKAGE.

Can you use a damaged grinding wheel?

NEVER USE A DAMAGED GRINDING WHEEL. Check the machine speed against the maximum operating speed of the grinding wheel. The speed of the grinding wheel must be equal to or greater than the machine’s speed. NEVER OVERSPEED A GRINDING WHEEL. Inspect the machine and its guards.

Can you mount a grinding wheel on a machine?

NEVER MOUNT A GRINDING WHEEL ON A MACHINE THAT IS NOT DESIGNED FOR THAT GRINDING WHEEL. Use proper mounting blotters when required or supplied by the manufacturer. Do not reuse blotters and use only one blotter for each side of the wheel.

Grinding wheel loading up!?!

I have a 8" grinder that I use primarily to grind bronze/brass castings with. The wheel is aluminum oxide. My problem is that I just changed over to a new wheel and sure enough its loading right back up again. What is the best way to clean the bronze gunk out of the grinder wheel while keeping the face true? Thanks guys!

Bronze

Bronze is typically "snagged" at the foundry with a black Si carbide wheel. Black Silicone carbide is a tough boxy grain in a stout bond. Frequently in swing frame grinders, these wheels cut fast and take abuse. Cyclotronguy

Troubleshooting Guide

When you notice anything that's not quite right, always check these things first:

2. Wheel loading and glazing

Wheel grit is too fine - Try using a coarser grit or softer grade wheel.

Overview

Grinding wheels contains abrasive compounds for grinding and abrasive machining operations. Such wheels are also used in grinding machines.

The wheels are generally made with composite material . This consists of coarse-particle aggregate pressed and bonded together by a cementing matrix (called the bond in grinding wheel terminology) to form a solid, circular shape. Various profiles and cross sections are available de…

Characteristics

There are five characteristics of a cutting wheel: abrasive material, grain size, wheel grade, grain spacing, and bond type. They are indicated by codes on the wheel's label.

The abrasive aggregate is selected primarily according to the hardness of the material being cut. Chemical compatibility is also a concern. For example because carbon alloys with iron, silicon carbide is not suitable for use with iron-based metals like steel.

Types

To the right is an image of a straight wheel. These are by far the most common style of wheel and can be found on bench or pedestal grinders. They are used on the periphery only and therefore produce a slightly concave surface (hollow ground) on the part. This can be used to advantage on many tools such as chisels.

Straight Wheels are generally used for cylindrical, centreless, and surface grinding operations. W…

Use

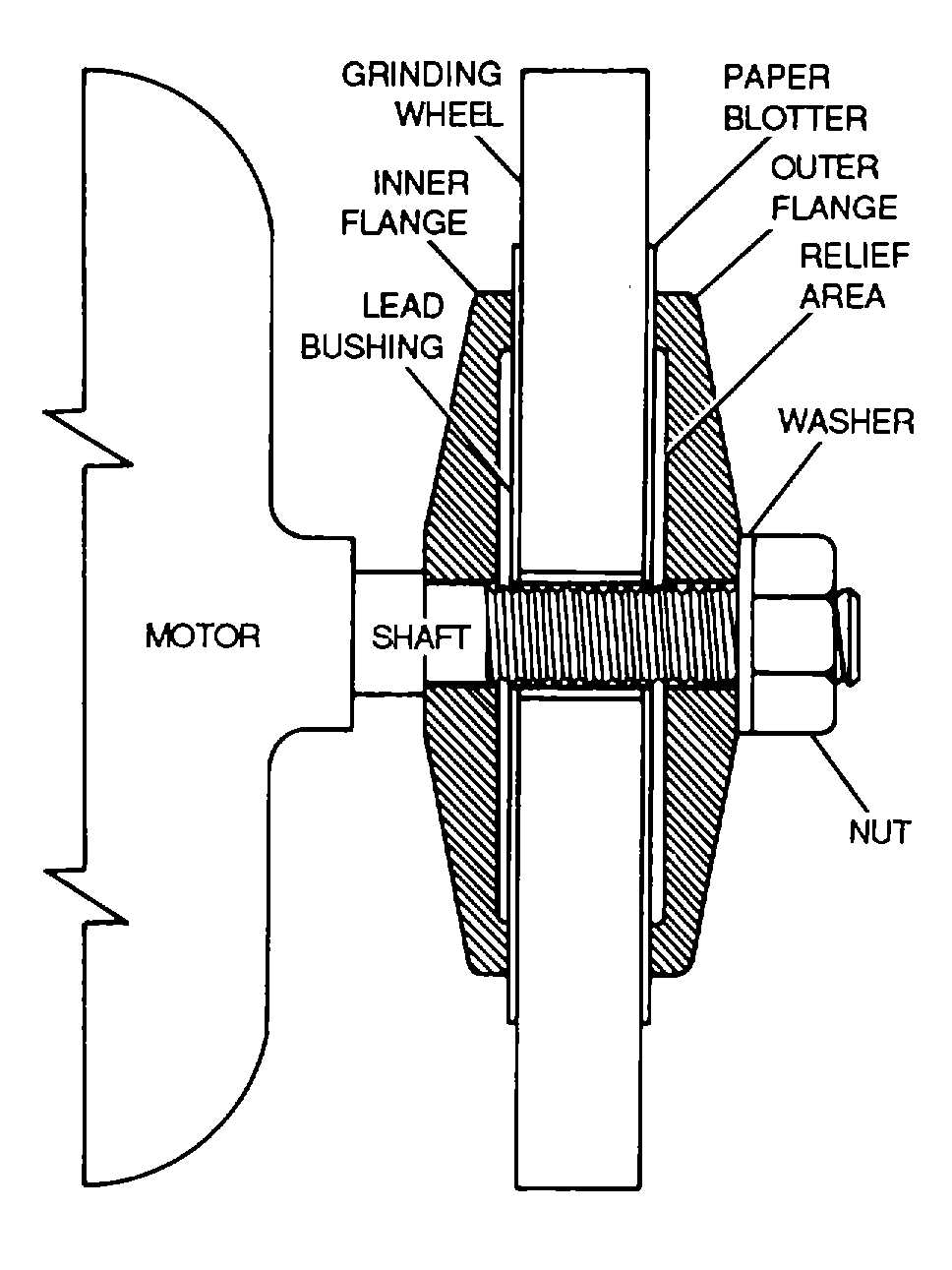

To use the grinding wheel it must first be clamped to the grinding machine. The wheel type (e.g. cup or plain wheel below) fit freely on their supporting arbors, the necessary clamping force to transfer the rotary motion being applied to the wheels side by identically sized flanges (metal discs). The paper blotter shown in the images is intended to distribute this clamping force evenly across the w…

Testing for grinding tools

Grinding wheels and grinding tools are used extensively in industry and manual trades for treating surfaces and for separating and cutting objects and have to withstand massive mechanical stress. Mostly centrifugal forces can cause a break, but also flexural and shear forces. Since a break or failure of the grinding tool can present a severe hazard to people and machinery due to the high levels of energy released, high standards are placed on the mechanical and breaking str…

See also

• Diamond tool

• Diamond grinding cup wheel

• Sharpening stone