Buffalo board is a fibrous material made of wood and other fibers compressed into boards. Buffalo board is commonly installed between 2 separate concrete slabs, such as between the concrete on your driveway and the concrete floor of the garage. Click to see full answer.

What is Buffalo Board made of?

20/01/2022 · Buffalo board is a fibrous substance composed of wood and other fibres that has been crushed into boards for use in construction. Buffalo board is typically used to connect two different concrete slabs, such as between the concrete on your driveway and the concrete floor of your garage, to provide a structurally sound foundation.

Who made the Buffalo Board?

18/04/2020 · Buffalo board is a fibrous material made of wood and other fibers compressed into boards. Buffalo board is commonly installed between 2 separate concrete slabs, such as between the concrete on your driveway and the concrete floor of the garage.

Is Buffalo Board good for flooring?

Buffaloboard ® Intense floor protection powers into the ranks of the best. Complete with all the features of the Expert range, with the addition of increased depth and durability, Intense is a cost effective and easy to install muilti-use floor protection always up to the challenge. A real hero.

What is buffalobuffalo board?

11/04/2019 · Buffalo board is a fibrous material made of wood and other fibers compressed into boards . Buffalo board is commonly installed between 2 separate concrete slabs, such as between the concrete on your driveway and the concrete floor of the garage.

Are Buffalo boards waterproof?

High durability boards such as ATP's Buffalo Board are regularly used in harsh environments where water and other contaminants will be found. The tough phonolic film surface on the plywood resists attack from many common chemicals and offers a waterproof finish.

What is Buffalo board made of?

The generic name is "fiberboard" and it is sold under many trade names like Celotex, Buffaloboard, etc. This stuff is not bad at all, it's just different from plywood and OSB.

Is Buffalo Board structural?

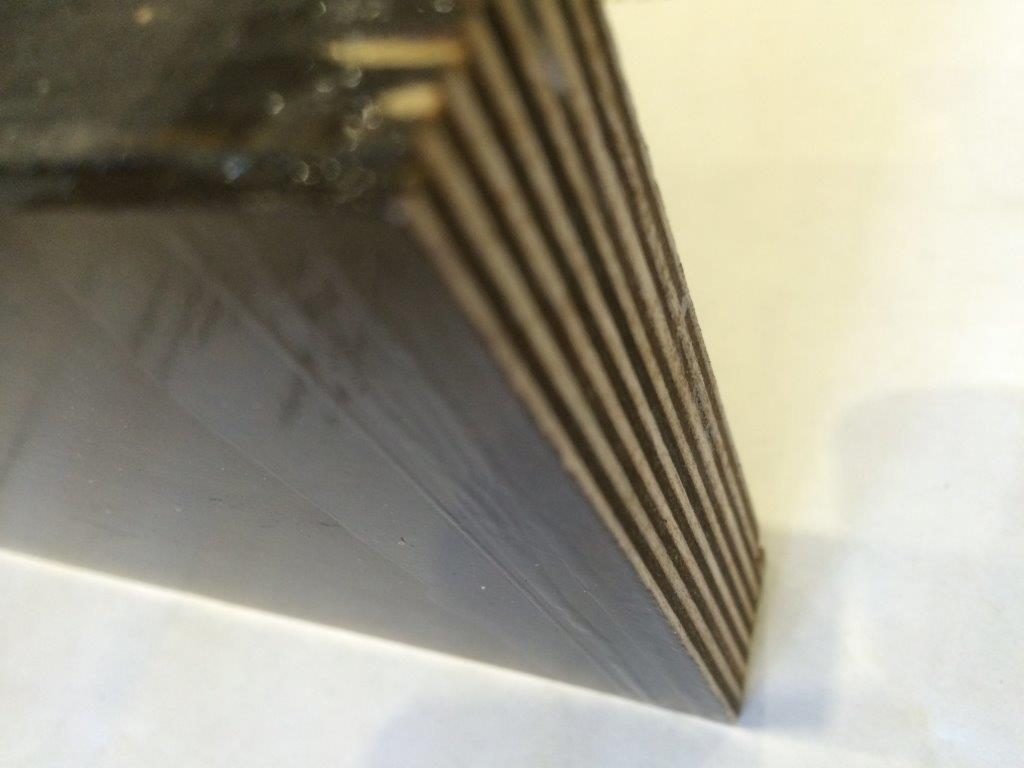

BUFFALO BOARD NON-SLIP BIRCH PLYWOOD Mainly used for commercial vehicle flooring, it has good chemical and weather resistance and can be used in structural applications.

Who makes Buffaloboard?

Buffaloboard ® | Swiftec Group.

What are Buffalo boards used for?

Buffalo® Board is a tough, anti slip plywood, suitable for a wide range of applications. This phenolic birch plywood is easily worked, can be CNC machined, and with good chemical and weather resistance, Buffalo® Board is the ideal choice for commercial vehicle flooring. Edges are sealed with acrylic resin paint.

What's another name for Buffalo board?

Beaverboard®, black board, buffalo board, gray board, cane board, Celotex®, Homasote®, Insulite®, Nu-Wood® are some of the many names of fiberboard or plant-fiber board sheathing products used on roofs, exterior walls, interior walls & ceilings.

What is asphalt impregnated board used for?

The cover board is adhered using hot asphalt or a specially formulated adhesive that is applied over the top surface of the bottom layer of insulation. Second, the cover board serves to insulate the fastener eliminating energy loss and possible thermal bridging at fasteners and insulation joints.02-Mar-2004

What is structural fiberboard sheathing?

Fiberboard structural sheathing is an engineered product made with ground up wood chips and lumber waste glued together with an asphalt binder or resin. The finish of fiberboard is uniform, with no knots or grains like those found in real wood.25-Mar-2020

Does beaver board contain asbestos?

Is there Asbestos in Beaverboard? Sarah: No, BEAVERBOARD is a wood fiber product not an asbestos-product.

What is phenolic board?

A phenolic board refers to a flat wooden sheet that has been soaked in phenolic resin. ... Due to the phenolic coating, the boards are moisture- and water-resistant, allowing them to be used in damp environments and spaces such as toilets and bathrooms.

What is phenolic ply?

Phenolic Plywood is common Eastern European or Scandinavian Birch plywood (EURO Birch or Baltic Birch) bonded with waterproof phenol resin adhesive and overlaid on both sides with the phenol film (grade F/F).14-Sept-2018

How long does it take for buffalo plywood to dry?

The high quality plywood used in Buffalo® and other Phenolic Boards is normally very well protected after 2 saturating applications. The board was then left to evaporate and dry out for half an hour. Two more cycles of soaking (5 minutes) and drying (30 minutes) were then performed.

Is Buffalo Board waterproof?

High durability boards such as ATP’s Buffalo Board are regularly used in harsh environments where water and other contaminants will be found. The tough phonolic film surface on the plywood resists attack from many common chemicals and offers a waterproof finish. However, the boards will have to be cut to size, or joined together, ...

Does Epoxy Resin have UV protection?

Protecting the edges of the sealed Buffalo Board from UV Light. In short – No Epoxy Resin has UV tolerance itself. UV blockers are sometimes added, or provided by top coatings. A customer asked if the sealed edges would necessarily need painting afterwards, as he didn’t want to get paint onto the top surfaces while painting the edges.

Do waterproofed edges need to be sealed?

Under some circumstances the waterproofed edges may now be required to be sealed to make a watertight join. Prior to performing any operation like this, please remember to allow sufficient gap for thermal expansion and contraction of the boards, which must be taken up by compression or expansion of the chosen sealant.

Can boat gents walk on wood?

The boat gents often treat a deck, and then wipe the top fibres clear with solvent to get a grippy surface so they can walk on it, and still gain significant benefits from the penetration of CPES into solid wood. This trick is described here maintaining a natural finish while protecting wood.