What does a tailstock do on the lathe?

The lathe tailstock is used to support the workpiece and keep it solid and straight in the lathe as it spins at high speed. Without the tailstock, long pieces of stock would simply deflect away when a cutting tool was pushed into it in an attempt to cut or shape it.

How does tailstock mechanism work in a lathe?

- spindle

- speed change mechanism, and

- change gears.

How to accurately cross drill on a metal lathe?

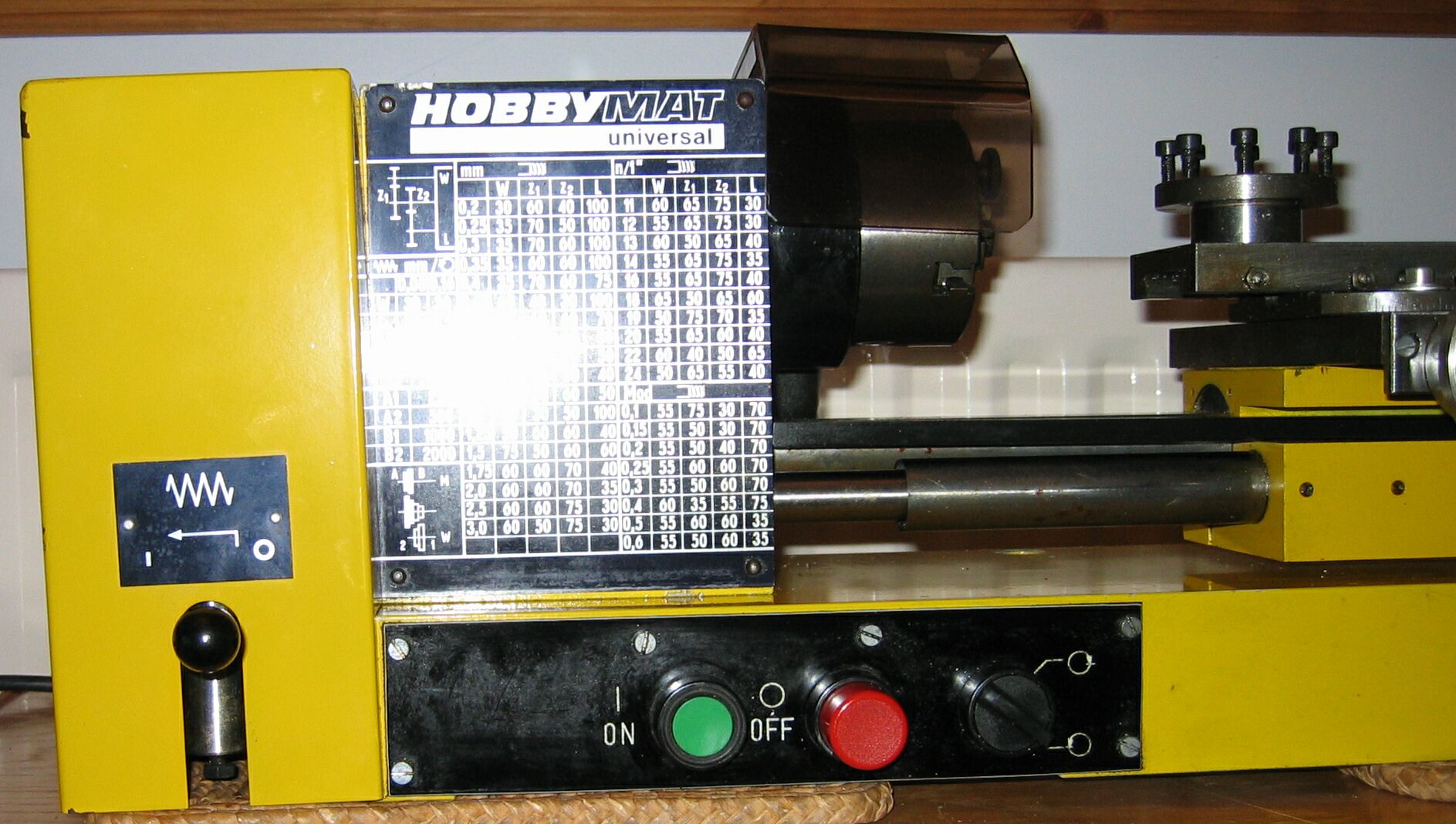

SPECIFICATIONS:

- Motor: 3/4 HP, 110V, single-phase 10A

- Swing over bed: 8-1/4"

- Swing over cross slide: 4-5/8"

- Swing over saddle: 6-7/8"

- Distance between centers: 15-3/4"

- Bed width: 4"

- Spindle bore: 0.787" (20mm)

- Spindle type: Intrinsic back plate

- Spindle taper: MT#3

- Tailstock taper: MT#2

What can you make with a metalwork lathe?

What I make with my metal lathe.....

- DBlue. Hello to all....I've been mostly a lurker here, reading as much as I can to learn from everyone here.

- Charley Davidson

- Dave Smith

- ARM. Hello to all....I've been mostly a lurker here, reading as much as I can to learn from everyone here.

- DBlue. Thanks very much.... ...

- clevinski. That's beautiful work!

- Ray C. Very nice work... ...

- DBlue. ...

- Ray C. ...

- Bill Gruby

What is the use of tailstock in lathe machine?

Often used as part of a lathe or in conjunction with a rotary table on a milling machine, a tailstock is designed to support the free end of a long work piece with a center during machine operations.

What are the two main uses of tailstock?

The tailstock is generally used to support the end of long workpieces, or it can be fitted with a drill chuck to drilling and other holemaking operations.The tailstock can be used to support the workpiece or hold tooling.The tailstock spindle can be fitted with tapered tools and toolholders.More items...

What is meant by tailstock?

Definition of tailstock : the adjustable or sliding head of a lathe containing the dead center.

What is headstock and tailstock?

The headstock supports one end of the workpiece and imparts rotational motion to the work. The tailstock merely supports the other end of the workpiece as it rotates.

What is the purpose of the tailstock on a lathe quizlet?

What two functions can the lathe tailstock perform? The tailstock can be used to secure work holding accessories to help support the workpiece in many operations. It can also hold cutting tools for performing standard hole making operations.

What are the main parts of lathe machine?

The main parts of the lathe are:Headstock: The headstock is usually located on the left side of the lathe and is equipped with gears, spindles, chucks, gear speed control levers, and feed controllers.Tailstock: ... Bed: ... Carriage: ... Lead Screw: ... Feed Rod: ... Chip Pan: ... Hand Wheel:

What are the parts of a metal lathe?

While there are different types of lathes, most feature a few basic parts to facilitate their operations.Bed. The bed is a large horizontal structure or beam that's used to support other parts of a lathe like the headstock and tailstock. ... Headstock. ... Tailstock. ... Carriage. ... Legs. ... Cross Slide. ... Saddle. ... Apron.

Why use tailstock on lathe?

It is also used on a lathe to hold drilling or reaming tools for machining a hole in the work piece.

What is a tailstock used for?

Tailstock used for drilling. A tailstock, also known as a foot stock, is a device often used as part of an engineering lathe, wood-turning lathe, or used in conjunction with a rotary table on a milling machine . It is usually used to apply support to the longitudinal rotary axis of a workpiece being machined.

How to move tailstock?

There, it is locked in place and the tool mounted to it is moved with a leadscrew to the exact position where it is needed. When a cutting tool such as a drill bit or reamer is used, the feed is done with this leadscrew. The tailstock quill or extendible portion usually has a Morse taper mount in the end of it to secure the drill or reamer. If the work is heavy the drill may be further secured from turning with a lathe dog as shown in the photo.

What is the taper mount on a tailstock?

The tailstock quill or extendible portion usually has a Morse taper mount in the end of it to secure the drill or reamer. If the work is heavy the drill may be further secured from turning with a lathe dog as shown in the photo.

When to use taper turning?

Generally, when the angle of taper is very small this taper turning methods in lathe machine will be employed. The workpiece be placed in the live center. Now, the tailstock will be moved in a crosswise, that is perpendicular to the lathe axis by turning the set over method. This process is known as tailstock set over method .

What is a fully programmable tailstock?

A fully programmable tailstock provides more rigidity and thermal stability. However, the tailstock casting adds weight to the machine. There are two basic types of programmable tailstocks—servo-driven and hydraulic. Servo-driven tailstocks are convenient, but the weight they can hold may be limited.

Why is a big lathe so powerful?

Generally, big lathes have high torque (twisting power) due to the weight of the mass spinning in the chuck. As a rule, the bigger the workpiece and the slower the spindle speed, the more torque required.

What is a belt driven spindle?

Belt-Driven or Direct-Drive Spindles. The spindle on a turning center is either belt-driven or direct-drive. Generally, belt-driven spindles represent older technology. They speed up and slow down at a lower rate than direct-drive spindles, which means cycle times can be longer. If you’re turning small-diameter parts, ...

What is CNC lathe?

Today’s CNC lathes are designed for specific ranges of stock diameters. Basically, you buy a machine to cut a specific, maximum workpiece diameter. If you’re cutting 2-inch-diameter barstock, the machine will be designed for running small diameters using higher-speed, 6,000-rpm spindles, and with the right amount of horsepower and torque.

Why is there a small degree of positional inaccuracy with belt driven spindles?

A small degree of positional inaccuracy may occur with belt-driven spindles, because the belt between the drive and the positional encoders creates a lag. With integral direct-drive spindles, this is not the case. Ramping up and down with a direct drive-spindle happens at a high rate, and the positional accuracy also is high, a significant benefit when using C-axis travel on live-tooling machines.

How many parts are in the series about buying turning machines?

This is part three of a four-part series about buying turning machines.

Can a big bore lathe be used for small diameter work?

Obviously, it doesn’t make sense to use a big-bore lathe to do small-diameter work. The operation that typically requires peak horsepower is heavy-duty, inner-diameter work, such as using big drills to make holes in the barstock before finish-boring. In this case, Z-axis horsepower might be the limiting factor.

What is a lathe tailstock used for?

The lathe tailstock is most commonly used for turning longish parallel or slightly tapered bars between centres and also for drilling and reaming. When turning, if the axis of the tailstock is not aligned concentrically with the the headstock axis the result will be a tapered bar.

Why are tailstocks a waste of material?

Many tailstocks have a scale as in the photo as an alignment guide but quite frankly most are a waste of material because even if fitted accurately it is impossible to align a tailstock to required standards of accuracy by eye.

How to check for alignment on a lathe?

1. Using a pre-made hardened and ground precision alignment bar. These bars are commercially available but can be made DIY if you have suitable facilities. They are made parallel to within small tolerances and are mounted between centres in the lathe. A test indicator will be mounted on the lathe saddle and traversed over the length of the bar. If you want the tailstock aligned for parallel turning or drilling, then you adjust it laterally to give a constant reading over the full length of the bar. If you want to turn a specific taper then you offset the alignment by an amount appropriate to the desired taper. For this method to be accurate it requires that the centre in the headstock runs true. To check vertical alignment you simply run the test indicator over the top of the bar rather than the side.

How to check for vertical alignment?

To check vertical alignment you simply run the test indicator over the top of the bar rather than the side . 2. The other method requires that you mount a bar between centres and take a small cut over its length.

How long should a steel bar be?

A length of steel bar, the diameter is not very important as long as it is rigid enough. I would suggest a minimum of 25mm (1 "). The length should be similar to the length of work pieces to be machined. It is better to have it too long, any excess length can be put up inside the headstock spindle.

Can you set a tailstock before checking alignment?

However, it is generally economically not feasible to set the tailstock in arbitrary positions if using the standard checking bar. You would need a multitude of bars. Using the method of machining a bar does not have this problem because you can just machine a bar with the same or similar length as the work piece. However, machining a bar for setting is slow, tedious and wasteful of material.

Do you have to have a lathe to make a lathe?

A lathe. You will not be doing this unless you have a lathe.

What is the tailstock on a lathe?

The tailstock sits opposite to the chuck and helps hold the work piece firmly and parallel. If you are turning a short piece of material, you won’t need the tailstock. Also if you are boring or drilling on a lathe you can’t use the tailstock.

Why do tailstocks slide along?

Tailstock slides along to accommodate different lengths of workpiece being worked out.

What is the spindle on a lathe?

On a lathe, the spindle will usually hold a chuck (which holds and rotates the work piece). The tailstock sits opposite to the chuck and helps hold the work piece firmly and parallel. If you are turning a short piece of material, you won’t need the tailstock.

What is a hollow cylindrical shaft?

Hollow cylindrical shaft. The main spindle is hollow in order for long bars to extend through to the work area. It is supported by precision bearings and is fitted with chucks or faceplates to hold workpieces. A taper is often included at the end of the spindle.

What side is the headstock on?

Headstock : It's on the left hand side and it has the live centre (means it rotates, just in case, rotation is needed). It has gears, spindle, pulleys. Headstock spindle is hollow cylindrical shaft that provides a drive from motor to work the holding device. . .

Why use magnetic chuck?

If the workpiece is ferrous thin type then we use magnetic chuck for ease of operation.

What is a lathe?

Continue Reading. A lathe is a machine tool primarily used for shaping pieces of metal and sometimes wood or other materials. Lathes operate by spinning the block of material to perform various tasks such as cutting, sanding, or drilling with tools that are applied to the work piece.