What does S3s mean on wood?

It stands for “Surfaced Three Sides”, which, as used in Goosebay’s hardwood lumber descriptions, indicates that two faces have been planed, and one edge has been processed with a straight-line rip saw, rendering the edge straight and smooth.

What does S2S mean in lumber?

S2S is a board surfaced on both faces with parallel faces. SLR stands for straight line rip meaning a board has one straight edge. RGH stands for rough which would be hardwood lumber yet to be dimensioned. What does S4S mean in hardwood lumber?

What does S3s mean on a surfboard?

S3S – The board has been surfaced S2S first, then one edge is ripped straight (also known as SLR1E or straight line ripped one edge). S4S – The board has been surfaced on both faces (S2S) and received a rip on both edges, resulting in a board with two flat and parallel faces and two flat and parallel edges.

What is the difference between S3s and S4s boards?

S3S boards are like S2S boards, with two flat faces, but additionally also have one ripped straight side. S4S boards have two surfaced faces, and two ripped sides, resulting in perfectly square, flat, and parallel edges on all four sides. This is the type of lumber you will find in most consumer hardware and DIY stores.

What is the best grade of lumber?

Hardwood grades are: FAS (First and Second) is the highest grade of hardwood lumber. It's usually 6-inches x 8-inches and is 83 percent defect-free on its best side. Select is 4-inches x 6-inches and 83 percent defect free on its best side.

What is S4S timber?

S4S, or lumber surfaced four sides, is another common surfacing option. This refers to boards being planed and in addition also being straight line ripped on two sides resulting in the board being flat, uniformed in thickness and squared up with parallel edges ready for the manufacturing process.

What does S2S mean when reference to hardwood lumber?

Surfaced two sidesRLW Random lengths and widths. S1S Surfaced one side. S2S Surfaced two sides.

What is the difference between rough sawn S2S and S4S?

The SxS designation simply refers to how many sides have been pre-surfaced. S2S= surfaced two sides, S3S = surfaced three sides and s4s = surfaced four sides. S2S – The board has been run through a planer producing two flat faces, but the edges are left rough.

What does BTR mean in lumber?

BetterGrades:BTRBetterB&BB & BetterCON COMConstruction Common RedwoodCON HEARTConstruction Heart RedwoodSTD BTRStandard & Better3 more rows

Is S4S lumber treated?

This #1 grade treated timber is approved for ground contact. This #1 grade treated timber is approved for ground contact....VIEW PRODUCTS & SERVICES IN YOUR AREA.Pack SizePack Size 1Board LengthBoard Length 8'TreatmentTreatment Copper-basedProduct Type1Product Type1 Treated Lumber7 more rows

What does S2S mean?

S2S means "Safe To Say" or "Sorry To Say."

How many board feet are in a 2x4x10?

6.66667A 2x4x10 board has 6.66667 total board feet in it: the board foot factor (BFF) of a 2×4 is 0.666667. Multiply 0.66667 by the length of 10 which gives total board feet of 6.66667.

What does WP4 mean in lumber?

Tongue & GrooveOur most popular. Large Red & Black Knots. Available in Clear Coat only. Tongue & Groove (WP4)

What does SYP mean in lumber?

Southern Yellow Pine lumberSouthern Yellow Pine lumber products are an excellent choice for general construction purposes due to the following properties: It's extremely dense therefore has exceptional strength properties.

What does E2E mean in lumber?

Hardwood, softwood, and MDF boards are offered as eased two edges (E2E) and surfaced four sides (S4S).

What does Rgh mean in lumber?

Rough cut lumberAll milled lumber is sold on a rough board foot basis. Example : 4/4 surfaced lumber milled to ¾” is measured based on a full inch thickness. Rgh: Rough cut lumber will require surfacing to achieve a smooth finish. S2S: surfacing of lumber on two faces. S3S: surfacing of lumber on two faces and ripping one edge.

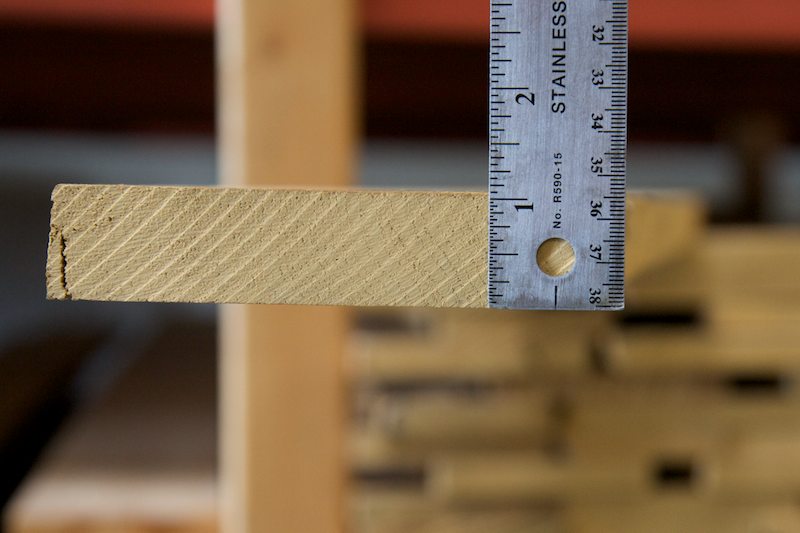

What is 4/4 lumber?

Lumber size is often referred to as 4/4 (pronounced FOUR-QUARTER), 5/4 (FIVE-QUARTER), 6/4 (SIX-QUARTER), etc. This refers to the thickness of the lumber when it is first sawn and in its rough dimensions. 4/4 lumber is sawn in the rough to a full 1 inch. The size increases in 1/4″ increments. 5/4 lumber is sawn.

What is FAS hardwood?

FAS, or Firsts and Seconds, is the hardwood grade which includes the superior “furniture grade” hardwoods. This grade is typically free of defects, but some defects are allowed.

What does RGH mean on a saw?

“RGH” indicates that the specified material is being sold as it came off the saw. It is in its “rough” state. This material is not planer-finished and will have no jointed edges.

What is the angle of a flat sawn board?

A flat sawn, or plain sawn, board has a ring-to-face angle of 30º to 0º. These are the boards sawn from the edge of the log and comprise the least stable lumber in the log.

Trip

I’d call around to your local cabinet shops, stair builders, etc… Two things, well maybe three…

Eric

It's a love/hate for me. If I'm wanting thicker boards for some reason then it sucks to only have surfaced material available. But usually I prefer surfaced because you can see exactly what you're getting. There's nothing worse than milling a rough board and finding out it's butt ugly. Money down the toilet.

ResidentEvil

I like being able to see the board with stuff that is surfaced. I just took a piece of rough walnut that I had purchased a while back and planed it down only to find that a majority of it was sapwood.

Eric

You pay extra for the surfacing because of the labor and machine wear. You can buy rough for cheaper, but it's a craps shoot how a board looks.

bushwacked

You pay extra for the surfacing because of the labor and machine wear. You can buy rough for cheaper, but it's a craps shoot how a board looks.

bushwacked

Good luck with that... I've yet to enter a yard/mill where that sort of thing would be tolerated... Maybe if you’re from a magazine, you get an all-access backstage press pass, but that’s not for the proles.

Jfitz

I asked a guy at my local lumberyard about using a small black plane to check a board. He very nicely and politely said no, but in a way that made it very clear. I don't blame him - the last thing they need is a bunch of old scrapes all over a board, and then someone wanting a discount because of all the "damage".