Accordingly, there are two basic types of pumps: dynamic and positive displacement pumps. Dynamic Pumps In dynamic pumps, the energy transfer is continuous. Dynamic pumps are categorized into three main types:

Full Answer

What are the three types of injection?

Why is knee injection done?

- Steroid injections

- Infliximab injections

- Hyaluronic acid injection. Hyaluronic acid (HA) is naturally present in the joints, eyes, and skin. ...

- Botox injection. Botox inhibits the sensory neurons causing pain. ...

- Platelet-rich plasma (PRP) injections. PRP is obtained from the patient’s own blood. ...

How to tell if injection pump is bad?

How to determine if fuel injector pump is bad?

- zetan. Glow plugs test - use an ohm meter and read the resistance between the block and the glow plug terminal.

- smackzed. Zetan is giving a sort of non specific answer because he doesn't know all the symptoms of your truck.

- smackzed. Sounds like because the engine is still warm. ...

- 82chev. ...

- DirrtyDetroit. ...

- koots. ...

- smackzed. ...

- smackzed. ...

- 93GMC2500. ...

- Jeffrey Brooks. ...

What does injection pump stand for?

for more unique definitions from across the web! What does INJECTION PUMP mean? An Injection Pump is the device that pumps diesel (as the fuel) into the cylinders of a diesel engine. Traditionally, the injection pump is driven indirectly from the crankshaft by gears, chains or a toothed belt (often the timing belt) that also drives the camshaft.

How noisy should a fuel injection pump be?

Fuel injectors do make a noise, but it would usually be described as a “buzzing” rather than a “ticking”. If you could figure out a way to remove the injectors from the engine but keep them hooked up to the fuel rail and electrical connectors, aim them at a container to catch the gas, and get them to go into inject mode while the fuel pump was running, then you’d know for certain.

What are the two types of mechanical injection pump?

These are basically low-pressure type of fuel pumps, sometimes also used for high pressure, whose main work is to transfer the fuel from tank to the fuel bowl of the spark ignition engine. The mechanical fuel pump consists of two kind of pumps; i.e.; diaphragm type fuel pump and plunger type fuel pump.

What are the 2 basic types of fuel injection systems?

Single-point or throttle body injection. Port or multipoint fuel injection.

What are the two types of diesel injection pumps?

The Different Types of Diesel Fuel PumpsDistributor Pump Type. A distributor pump is a kind of injection pump with a smaller design. ... Continuous Pump. This pump is the latest type of diesel injection pump and the most widely applied pump type today. ... Individual Inline Pump.

What type of pump is an injection pump?

An Injection Pump is the device that pumps fuel into the cylinders of a diesel engine. Traditionally, the injection pump was driven indirectly from the crankshaft by gears, chains or a toothed belt (often the timing belt) that also drives the camshaft.

What is mechanical fuel injection?

Mechanical fuel injection is a type of fuel delivery system that, as the name implies, relies primarily on mechanical methods to inject fuel into an engine. It preceded. electronic fuel injection. and was designed to offer a more consistent method of delivering fuel.

What are the types of injection system?

The basic types of fuel injection systems are single-point fuel injection, multi-point fuel injection, sequential fuel injection, and direct injection.

How does a mechanical injection pump work?

Mechanical fuel injection works with a simple throttle-controlled air valve and a fuel pump, usually running at one-half engine speed. After pulling fuel from a vented fuel tank, the fuel is delivered through a barrel valve that controls the amount of fuel with the position of the air valve.

What is the difference between inline injection pump and rotary pump?

An inline pump is a bit different from the rotary pump. Where the rotary pump has the output lines in a circle, and inline pump has them all in a straight line. Unlike other types of fuel pumps, each cylinder on an inline pump operates on its own, also allowing them to fail separately.

What is the difference between DI and Crdi?

The maximum engine power of DI 4WD, which is 63 bhp @ 3800 rpm, is more than that of CRDE, which has 105 BHP @ 3800 RPM. Similarly, CRDE has a greater torque of 247 Nm @ 1800 RPM in comparison of that of DI 4WD which has 182.5 Nm @ 1500 Rpm.

How does a mechanical diesel injector pump work?

3:167:03Animation - Working of Fuel Injection Pump. - YouTubeYouTubeStart of suggested clipEnd of suggested clipThe accelerator pedal or when we release the accelerator pedal this accelerator cable actuallyMoreThe accelerator pedal or when we release the accelerator pedal this accelerator cable actually controls the movement of the throttle well which gives a demand towards the fuel injection pump.

What fuels are used in mechanical fuel injection?

While methanol and nitromethane are common fuels, other fuels such as ethanol or race gas can also be used in mechanical fuel injection. Illustration of mechanical fuel injection expanded with the addition of an idle control circuit, barrel valve, and multiple nozzles feeding a throttle valve hat assembly.

Why are injectors added to a multi cylinder engine?

Additional components are added for air and throttle control for power modulation. Additional injectors are added to provide fuel to each cylinder of a multi-cylinder engine with any number of cylinders, regardless of whether it is a two-cycle, four-cycle, or rotary engine configuration.

What is MFI fuel jet?

MFI fuel bypass jets control the fuel mixture to the engine. These jets divert a certain amount of fuel away from the engine and back to the fuel tank, which is useful for controlling the overall fuel flow to the engine. Additionally, high-speed bypass jets come on when the engine reaches a certain engine speed.

What is a fuel pump?

Hoses or tubing to carry the fuel from one component to the other. A mechanical fuel pump sized for the type of fuel, power level, and engine RPM range. Injector hoses, distribution block, and injector lines to feed the injector nozzles. Injector nozzles to inject the fuel into the air stream going into the engine.

What is a jet in fuel injection?

A jet restricts the flow and controls the amount of fuel delivered to the engine. Changing the size of the main bypass jet is one way to tune a mechanical fuel injection setup, as a bigger jet leans the engine while a smaller jet richens the engine.

How big is a fuel pump?

Fuel pump size is important. Normal installations involve a fuel pump about 25- to 50-percent larger than the engine demand. Tuning is simple by controlling the amount of excess fuel bypass back to the fuel supply. In addition, the fuel pump should be fed with an adequate supply line to avoid inlet cavitation.

What is barrel valve?

A barrel valve or metering valve controls the appropriate amount of fuel for starting, part-throttle, driving, and stopping. A barrel valve is also used to throttle the fuel for part-throttle driving. Most barrel valves have a very simple spool or metering cylinder inside of the valve for controlling the fuel flow.

What is an injection pump?

An Injection Pump is the device that pumps fuel into the cylinders of a diesel engine. Traditionally, the injection pump was driven indirectly from the crankshaft by gears, chains or a toothed belt (often the timing belt) that also drives the camshaft.

How does an injection pump work?

Traditionally, the inject ion pump was driven indirectly from the crankshaft by gears, chains or a toothed belt (often the timing belt) that also drives the camshaft. It rotates at half crankshaft speed in a conventional four-stroke diesel engine.

Why are mechanical pumps being phased out?

Mechanical pumps are gradually being phased out in order to comply with international emissions directives, and to increase performance and economy. From the 1990s an intermediate stage between full electronic control were pumps that used electronic control units to control some of the functions of the rotary pump but were still mechanically timed and powered by the engine. The first generation four and five cylinder VW/Audi TDI engines pioneered these pumps before switching to Unit Injectors. These pumps were used to provide better injection control and refinement for car diesel engines as they changed from indirect injection to much more efficient but inherently less refined direct injection engines in the 1990s. The ECUs could even vary the damping of hydraulic engine mounts to aid refinement. BOSCH VP30 VP37 VP44 are example pumps. Since then there has been a widespread change to common rail diesel systems and electronic unit direct injection systems. These allow for higher pressures to be developed, and for much finer control of injection volumes, and multiple injection stages compared to mechanical systems.

How do diesel pumps work?

Earlier diesel pumps used an in-line layout with a series of cam-operated injection cylinders in a line , rather like a miniature inline engine. The pistons have a constant stroke volume, and injection volume (i.e., throttling) is controlled by rotating the cylinders against a cut-off port that aligns with a helical slot in the cylinder. When all the cylinders are rotated at once, they simultaneously vary their injection volume to produce more or less power from the engine. Inline pumps still find favour on large multi-cylinder engines such as those on trucks, construction plant, static engines and agricultural vehicles.

Can diesel be injected into skin?

This is a good reason to take great care when working on diesel systems; escaping fuel at this sort of pressure can easily penetrate skin and clothes, and be injected into body tissues with medical consequences serious enough to warrant amputation.

Basics of Pumps

A pump is a machine to transfer fluids (liquids or gases), or even slurries, by converting the electrical energy into mechanical action.

Classification of Pumps

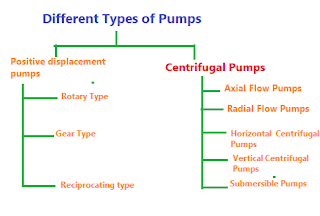

Pumps can be classified in different ways, as said at the beginning of this article. In this section, we will describe the classification by general mechanical configuration. Accordingly, there are two basic types of pumps: dynamic and positive displacement pumps.

Dynamic Pumps

In dynamic pumps, the energy transfer is continuous. Dynamic pumps are categorized into three main types:

What is piston pump?

Piston pumps. A piston pump is a type of positive displacement pump where the high-pressure seal reciprocates with the piston. Piston pumps can be used in multiple applications and can be used to transfer paint, chocolate, pastry, etc.

What is a diaphragm pump?

Diaphragm pumps. There are 2 main types of diaphragm pumps: Air-operated and Mechanical. As the name suggested, air-operated diaphragm pumps (aka AOD pumps or AODD pumps) are powered solely by air making them suitable for dangerous and tough environments.

What is a peristaltic pump?

Peristaltic pumps creates a steady flow for dosing and blending and is able to pump a variety of fluids, ranging from toothpaste to all sorts of chemicals. They are widely used in water treatment, chemical processing and food processing industries.

How do gear pumps work?

Gear pumps transfer fluid by gears coming in and out of mesh to create a non-pulsating pumping action. They are able to pump at high pressures and excel at pumping high viscosity liquids efficiently.

What is pumping in science?

A pump is a device which moves fluids by mechanical action, from one place to the other. It is, essentially, the earliest form of machine, dating back to ancient Egypt.

Is a fire pump a pump?

Fire hydrant pump system (also known as fire pump, hydrant booster, fire water pump) is technically not a pump but a system by itself. The hydrant booster pump usually consists of 1 centrifugal pump and other components such as control panel and coupled with either a diesel or electric driven motor.

What kind of pump produces an enhancement within force by transmitting mechanical power from the electrical motor to the liquid throughout the

The change of pressure will drive the liquid throughout the system. Centrifugal Pumps. This kind of pump produces an enhancement within force by transmitting mechanical power from the electrical motor to the liquid throughout the revolving impeller.

What are the pumps used in buildings?

These are used in different kinds of buildings to make simpler the movement of liquid materials. The pumps which are used in housing & commercial can handle water. Fire pumps supply a rushed water supply for automatic sprinklers and firefighters, and booster pumps supply clean water to higher floors in apartments.

What is a fire pump?

These are high force water pumps intended to enhance the capacity of fire fighting of construction by increasing the force within the hydrant service as mains is not sufficient. The applications of this system mainly include irrigation as well as water transfer.

What is a vertical centrifugal pump?

Vertical centrifugal pumps are also called as cantilever pumps. These pump s use an exclusive shaft & maintain design that permits the volume to fall within the pit as the bearings are external to the pit. This mode of pump utilizes no filling container to cover the shaft however in its place uses a throttle bushing.

What type of pump is most commonly used worldwide?

1). Centrifugal Pumps. These types of pumps are most commonly used worldwide. The working is very simple, described well and carefully tested. This pump is strong, efficient and fairly cheap to make. Whenever the pump is in action, then the fluid pressure will increase from the inlet of the pump to its outlet.

What is a peristaltic pump?

These are a kind of positive displacement pumps and the applications of these pumps mainly involve in processing of chemical, food, and water treatment industries.

What is pump basics?

What is pump & basics. Pumps are of various types. These are operating based on various design principles. Working philosophy are different for different pumps. It needs a driver to operate. Driver may be motor or engine or gas or turbine etc. driven.

What is pump in motor?

Pump Definition. The pump has a driving component that is a motor (sometimes may be an engine), and a power source is connected to the motor. Once the pump is switched ON, electricity is supplied to the motor, and. the pump does a mechanical action and changed the electrical energy into hydraulic energy, and.

What is NPSHr in pumps?

NPSHr means NPSH required for the pump selection. It is one of the main function for the selection of pumps so that pump will not have any cavitation problem during operation. It is the lowest value of NPSH in which pump will run without any cavitation. It is normally provided by manufacturer.

How does a reciprocating pump work?

In case of a reciprocating pump, the piston is connected to the crank through the connecting rod, and the crank is connected to a driver. After sucking the fluid, the piston moves opposite, and pressure is generated on the fluid. Hence, we have got the basics of the pump working philosophy.

How do centrifugal pumps work?

Centrifugal pumps are used to transfer liquid by converting mechanical energy into hydraulic energy. Pumps basics centrifugal pumps. This pump creates centrifugal force by the rotation of impeller. It transfers transfer liquid from one place to another place. The main force is centrifugal force.

How does a rotary pump work?

Rotary pump transfers fluids by using a rotating mechanism. It creates low pressure or vacuum and take up the fluids from the source. After taking up, due to the rotation, fluid is transferred.

What is the role of a volute in a centrifugal pump?

In a centrifugal pump, volute and diffuser help to increase the pressure of the fluid. Centrifugal force is created due to the rotation of the impeller and this force is acted on the fluid too.