When running gasless welding wire – connect the Earth to positive and Torch to negative, otherwise known as "DC electrode negative", or "straight polarity". (This is the opposite to standard MIG welding with gas, which is torch/wire positive and earth negative). Click to see full answer.

Is Earth positive or negative on a gasless welder?

When running gasless welding wire – connect the Earth to positive and Torch to negative, otherwise known as "DC electrode negative", or "straight polarity". (This is the opposite to standard MIG welding with gas, which is torch/wire positive and earth negative).

What is the difference between positive and negative current in welding?

Welding currents with electrode-positive (reverse) polarity result in deeper penetration, while electrode-negative (straight) polarity has the benefit of faster melt-off and faster deposition rate. Different shielding gases may further affect the weld as well. 2 What do AC and DC current mean?

What is the polarity of a welder?

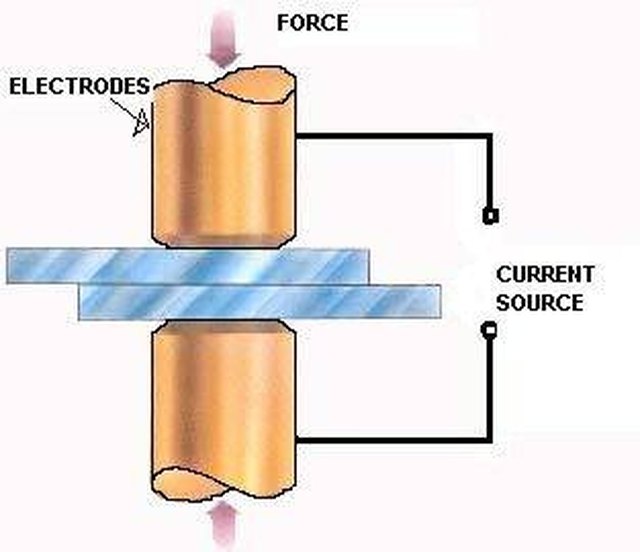

The electrical circuit that is created when you turn on the welder has a negative and a positive pole – this property is called polarity. Polarity matters greatly in welding because choosing the right polarity affects the strength and quality of the weld.

What is a positive and negative stud on a welding torch?

Common welding power sources have a positive (+) stud and a negative (-) stud. You attach a cable leading to the electrode (a wire feeder, a shielded-metal arc welding stinger, or a gas tungsten arc welding torch) to one and connect a cable leading to a work-lead clamp to the other.

Why does polarity matter in welding?

Polarity matters greatly in welding because choosing the right polarity affects the strength and quality of the weld. Using the wrong polarity will lead to lots of spatter, bad penetration, and a lack of control of your welding arc. 1.

Why do welders use AC?

Some welders choose AC if they want to avoid deep penetration, such as in repair work on rusty metals. Understanding welding currents and polarity is important for completing a welding job correctly.

What is the difference between AC and DC welding?

Therefore, welding machines and electrodes labeled “DC” have constant polarity, whereas those labeled “AC” change polarity 120 times per second with a 60-hertz current.

Why is DC welding used?

In shielded metal arc welding (SMAW), DC is widely used because of its many benefits. Welding with DC creates smoother and more stable arcs, you can strike the arc more easily, there are fewer arc outages and less spatter, and vertical up and overhead welding is also less complicated.

Is TWS a good training?

TWS is a Great Training Option for Everyone. Learn more about how we can prepare you to advance your career. Info for. Parents. Out of State Students. Adult. Students. Military Students. Welding is a hands-on job, but welders still have to have a fair amount of technical knowledge.

What happens if you hook up a stick welding lead?

Welding leads come in different sizes. While hooking up stick welding leads, you should be extremely conscious about their size. If your cable selection is wrong, you won’t be able to get the desired current and voltage to the welding arc. Consequently, problems like excessive spatter and lack of fusion can occur.

How to connect a welding lead to a welder?

2. Hook up welding leads to the welder. After that, attach the work lead to the negative terminal of the welding machine and electrode cable to the positive terminal. You can also make connections opposite to this depending upon the welding application.

How to connect DCEP to a negative?

For DCEP or direct current electrode positive connection (formerly known as reverse polarity), you have to connect the electrode holder to the positive terminal and the ground clamp to the negative one. As a result, electrons will flow from the workpiece towards the electrode.

What are the three ways to connect welding leads?

You can connect the welding leads in three different ways called the DCEN connection, DCEP connection, and the AC connection . Each connection has its pros and cons. They should be changed according to the welding application they are being used in.

What is a stick welding?

SMAW or stick welding. Shielded Metal Arc Welding, commonly known as stick welding is the most popular form of arc welding. It uses electrical current (usually DC) to melt both the metal workpiece and the electrode rod, forming a weld pool.

How to attach a ground clamp to a welder?

You can either clip it directly to the workpiece or to the metallic table on which your work is to be done (as shown in the figure). 2. Hook up welding leads to the welder.

What is a welding lead?

Welding leads or welding cables, just like other copper wires, are electrical conductors wrapped inside an insulating rubber jacket. These cables come in different diameters and lengths. For high current applications, we use cables with a large diameter as they offer less resistance to the current.

How to switch a stick welder to a tig?

If you want to run a scratch start TIG setup off your existing stick welder or engine drive, simply switch the DCEP (positive) setup to a DCEN (negative) setup. Switch your leads to opposite terminals – so your stinger lead is now negative and your ground clamp is now positive.

What is DCEN welding?

This means that the torch hose is attached to the negative terminal of your machine, and the ground clamp lead is attached to the positive terminal on your machine.

Do you need AC for tig welding?

Aluminum TIG welding will require alternating current or AC, in which the machine is constantly reversing between positive and negative currents. Lower end machines usually don’t have this feature. It is essential for TIG welding aluminum, but isn’t as common for hobbyists or general home applications. However, If you plan on TIG welding aluminum, make sure your machine has AC. A good aluminum TIG welding video can be watched here from welding tips and tricks.

Can you change polarity while on an inverter?

Newer inverter machines will allow TIG polarity changes while the machine is on. These newer machines often have digital readouts that allow for quick amperage changes and TIG polarity changes. However, older transformer machines can get severely damaged if you change polarity while the machine is on. You can read more on welding machines in our guide here.

Can you change the polarity of a tig welding machine?

TIG welding polarity is pretty straightforward. Once you set up your machine, you shouldn’t have to change the terminal connections ever again – unless you want to stick weld . Newer inverter machines will allow TIG polarity changes while the machine is on.

Can you stick weld with a tig?

Some lower end machines will have the TIG leads/hoses hardwired in, with no option for adjustability. This means you can start TIG welding right away. However, if you want to stick weld, you’ll need some machine modifications.

Does tungsten work better on aluminum?

Newer machines will tend to ball the tungsten automatically on AC current, but the positive polarity trick listed above can be useful on older transformer machines. A rounded tungsten performs better on aluminum than a sharpened tungsten.

What is a welding power source?

Common welding power sources have a positive (+) stud and a negative (-) stud. You attach a cable leading to the electrode (a wire feeder, a shielded-metal arc welding stinger, or a gas tungsten arc welding torch) to one and connect a cable leading to a work-lead clamp to the other. The polarity required determines if the work lead runs from the + or - stud.

How does a machine ground?

Grounding is accomplished through the permanently attached power connection supplying the machine (the plug), or by a separate clamp and wire connecting the case or frame of the machine to ground (like the building). Sometimes both the plug and one of these wire connections is used. Again, they have nothing to do with the + or - stud on the machine.

Is a positive lead a ground?

You would be much better off referring to the leads coming off a power source as an electrode lead and a work lead, or a positive lead and a negative lead, but neither is ever considered to be a ground.

Does work lead ground anything?

In the article you’re referencing I state, "…the work lead does not ground anything." When you’re installing welding equipment, that statement is critical to remember. OSHA requires that your equipment be grounded to protect people from electric shock. The way equipment is grounded has nothing to do with the + or - stud on the front of the welding machine.