When you start your lawn mower or small engine, you turn the flywheel and its magnets pass the coil (or armature). This creates a spark. Once the engine is running, the flywheel keeps rotating, the magnets keep passing the coil and the spark plug keep firing based on a specific timing.

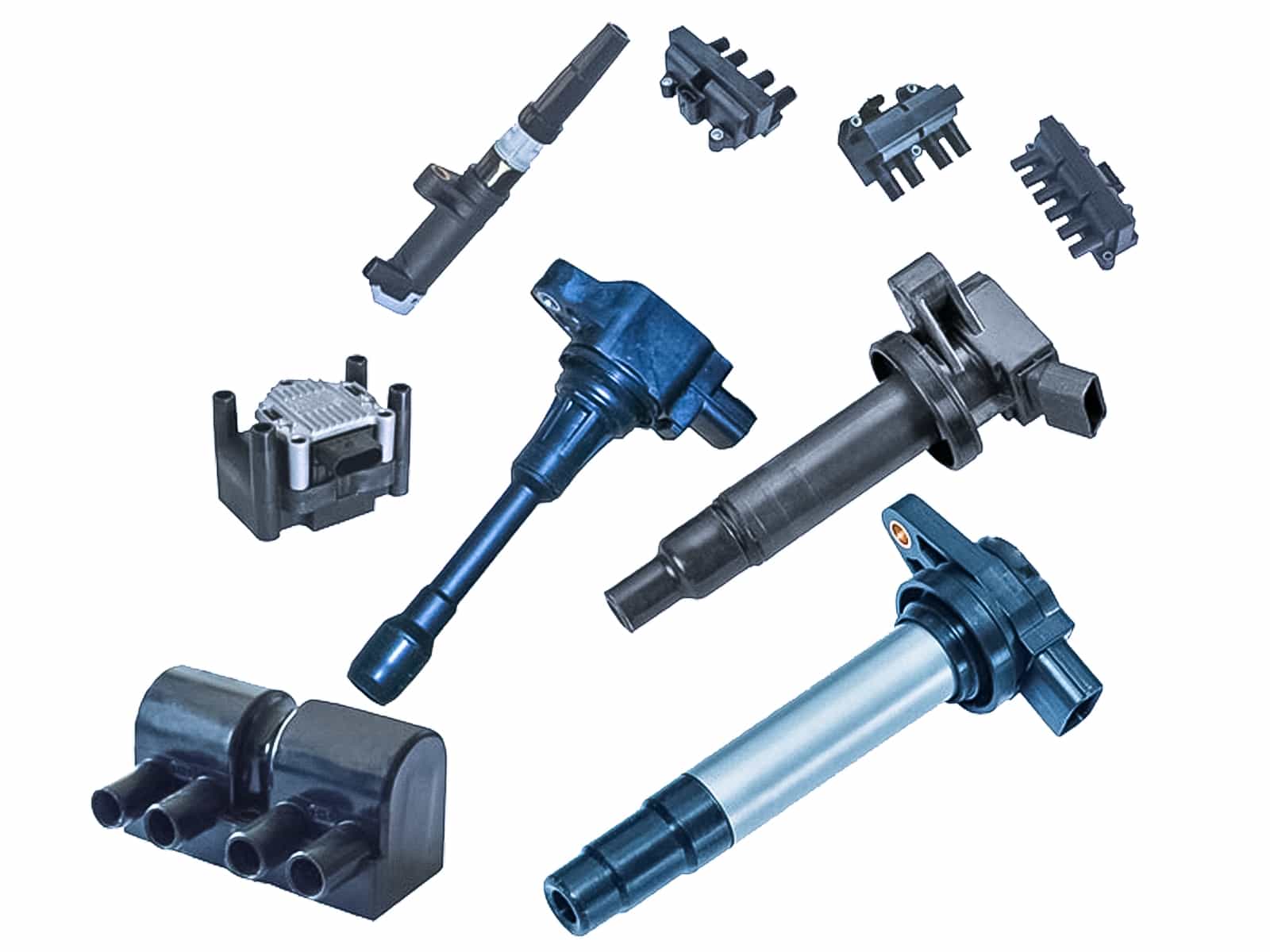

What is an ignition coil and why is it important?

- Loss of gasoline through the exhaust, which leads to your car backfiring.

- Oil deposits on the engine attracting dust and cause sludge formation.

- Overall degradation of the engine’s health.

- Improper power supply harming other parts of your car like suspension, tires, and more. ...

- Read the owner’s manual to note down the maintenance schedules.

How often should you replace your ignition coils?

- The car will not start

- The engine is misfiring on a regular basis

- The Check Engine Light is on

How to check ignition coils the easy way?

Testing a Spark Plug Ignition Coil in 7 Steps

- Research the specifications. Find out what the correct resistance reading of the ignition coils should be for your vehicle. ...

- Locate the ignition coil, or coils, on your vehicle. ...

- Disconnect the wiring harness for the ignition coils. ...

- Test the ignition coil’s primary ignition circuit. ...

- Test the secondary circuit of the ignition coil. ...

What is the function of the ignition coil?

What is the function of an ignition coil in a car?

- Engine misfires, rough idle, and loss of power. One of the most common symptoms associated with a faulty ignition coil is engine performance issues.

- Check Engine Light comes on.

- Car is not starting.

How do you test a small engine coil?

1:085:53How to test a small engine coil using a Multimeter. - YouTubeYouTubeStart of suggested clipEnd of suggested clipThe where the coil bolts onto the the mower or the stringer or whatever you touch the negative ontoMoreThe where the coil bolts onto the the mower or the stringer or whatever you touch the negative onto there. So you might need to just scratch it a little bit.

How does a small engine produce spark?

When you start your lawn mower or small engine, you turn the flywheel and its magnets pass the coil (or armature). This creates a spark.

How does a ignition system work in a lawnmower?

Electro-Magnetic Induction The ignition system starts a lawnmower and keeps it running by generating enough electric current to jump the gap between the electrodes of a spark plug, and to create a spark to ignite fuel in the combustion chamber.

How does a coil igniter work?

0:483:43How Ignition Coils Work - YouTubeYouTubeStart of suggested clipEnd of suggested clipThis coil is a kind of transformer a device that transfers voltage from one circuit to anotherMoreThis coil is a kind of transformer a device that transfers voltage from one circuit to another either as a lower voltage or in the case of the ignition coil as a higher voltage.

How many volts does a small engine coil produce?

The secondary coil, having 100 times more turns than the primary coil, amplifies this voltage to approximately 20,000 volts, and this voltage feeds to the spark plug. Many riding lawn mowers do have a battery if they have accessories like headlights and electric start.

What is the gap between ignition coil and flywheel?

Homelite advises that the gap between the ignition coil and the flywheel must be set anywhere from . 0012 to . 0013 inch for successful engine startup. If you've not replaced the ignition coil recently and your machine won't fire up, it may be possible that you simply need to check the gap and reset it if necessary.

How does a Briggs and Stratton ignition system work?

The ignition system coordinates the timing so that the spark will ignite the air-fuel mixture in the combustion chamber just as it reaches maximum compression in each engine cycle- thus, maximizing the engine's power.

What is the difference between a magneto and a coil?

A magneto is an engine driven device consisting of a rotating magnet and field poles. It needs no battery, and generates current to spark a spark plug. A coil is a device used in an ignition system that is actually a trsnsformer that steps battery voltage up to approx. 30,000 volts.

How do you fix a small ignition coil?

0:423:06Briggs & Stratton Small Engine Ignition Coil Replacement Part ...YouTubeStart of suggested clipEnd of suggested clipUse a quarter inch socket or nut driver to remove the mounting screws securing the coil. And pullMoreUse a quarter inch socket or nut driver to remove the mounting screws securing the coil. And pull the old coil. Off install the new ignition coil by aligning it on the engine.

What gives power to the ignition coil?

The battery provides low voltage electricity to the ignition coil. The ignition coil converts the low voltage electricity into high voltage power in timed pulses. The distributor has a shaft that gets spun by the camshaft.

How do you trigger an ignition coil?

1:267:59How to Trigger Internal Igniter Ignition Coils - YouTubeYouTubeStart of suggested clipEnd of suggested clipSo you have to have the proper pulse. Add this the right dwell or the right pulse width. And thenMoreSo you have to have the proper pulse. Add this the right dwell or the right pulse width. And then the other two eyes are the two ground so one the one ground is the main ground for the coil.

What happens if an engine is infinite?

If infinite (no continuity), an internal open circuit exists. Replace the coil. If infinite and the engine runs, your problem is an internal break of the high tension lead, a poor attachment of the spark plug terminal or improper mating of the high tension lead to the coil. A pin within the coil body skewers the lead.

How many volts does a spark plug need?

Spark Plug: The spark plug is a major element of the equation. A new spark plug may require around 10,000 volts to jump a .030" gap when the engine is cold. This drops to just 4,000 when the engine is hot as electrons are more easily emitted from a hot surface.

What happens if a pin does not contact the wire core?

If the pin does not contact the wire core, there will be no continuity. The coil will often have enough available voltage to jump the gap, so you see spark. The internal arcing that occurs within the high-tension lead will eventually create enough resistance that ignition system performance will suffer.

What is the flywheel magnet made of?

In a point style system, the flywheel magnets rotate past the legs of the ignition armature. The armature itself is made up of two separate windings of copper wire - the primary and secondary - one wound on top of the other. Basic physics tells us that when a magnetic field (flywheel magnet) cuts through (moves past) a conductor (copper wire), ...

What happens when electrons flow through a conductor?

Electron flow through a conductor then, causes a magnetic field. When the points close, electron flow causes a magnetic field to be created around the primary. This field also envelopes the secondary. The points now open, break the circuit and collapse the field through the primary.

Can Briggs and Stratton coils be made too wide?

Well, sort of not true. Briggs & Stratton air gaps cannot be made too wide to prevent spark providing the coil is healthy and the engine is spun over fast enough. A wide air gap, say .030" will ever so slightly retard the ignition timing as the magnetic field takes longer to build within the coil winding.

When a magnetic field cuts through a conductor, a flow of electrons is created?

However, electron flow only occurs when we have a complete circuit. This means that the points must be closed.

What is the ignition system?

The ignition system is the starting system for your small engine. Whether you start the engine with a pull rope or the turn of a key on an electric start motor, you're relying on the ignition system to produce a spark inside the combustion chamber. Small Engine Ignition Parts.

How to check a coil?

Step 1: Clip one end of the spark tester (service part number 19368) to the ignition cable and the other grounded to the cylinder head as shown below. Step 2: Spin the flywheel rapidly (at least 350 RPM) and watch for spark in the tester window.

What are some common mistakes when testing coils?

Common Mistakes When Testing Coils. Be sure to unhook the coil from the equipment wiring harness as well as the engine's wiring harness and use the spark tester. Many a technician is fooled into replacing a good coil because the coil grounding lead was shorting out against a piece of sheet metal.

Why does my ignition module fail?

When it does fail, it is usually due to heat caused from improper wiring of the ground wire to battery voltage.

What to do if your engine does not produce spark?

If the engine does not produce spark, other areas of the ignition system should be checked before focusing on the ignition module as source of failure (see above). If no fault is discovered in the above mentioned areas, the ignition module itself may need to be examined.

What to do if your engine is not connected to the equipment?

If the engine is not connected to the equipment, make sure the stop switch wire is not grounded. Step 5: Attempt to start the engine . A spark should be visible in the tester. If no spark appears, check for broken wires, shorts, grounds or a defective stop switch.

Can you turn off an engine without a grounding lead?

The engine may start. Without the grounding lead installed, you won't be able to turn it off. Replacing Ignition Coils or Armatures. An ignition armature must be set at a precise distance from the flywheel. Your engine repair manual will provide the proper gap for your engine.

What is the ignition system on a lawn mower?

The ignition system is the starting system for your small engine. Whether you start the engine with a pull rope or the turn of a key on an electric start motor, you're relying on the ignition system to produce a spark inside the combustion chamber. When you start your lawn mower or small engine, you turn the flywheel and its magnets pass the coil ...

Why does my ignition module fail?

When it does fail, it is usually due to heat caused from improper wiring of the ground wire to battery voltage.

How to turn a flywheel?

Turn the flywheel so the magnets are on the opposite side from the ignition coil (armature) Place the appropriate shim between the rim of the flywheel and the ignition armature. While holding the shim, turn the flywheel until the magnets are directly adjacent to the armature.

How does a lawn mower spark?

When you start your lawn mower or small engine, you turn the flywheel and its magnets pass the coil (or armature). This creates a spark. The ignition system coordinates the timing so that the spark will ignite the air-fuel mixture in the combustion chamber just as it reaches maximum compression in each engine cycle- thus, ...

What to do if there is no spark on a stop switch?

If no spark appears, check for broken wires, shorts, grounds or a defective stop switch. Once you have confirmed that the stop switch is working, reconnect the spark plug lead .

What to do if your engine has no spark?

Attempt to start the engine. A spark should be visible in the tester. If no spark appears, check for broken wires, shorts, grounds or a defective stop switch. Once you have confirmed that the stop switch is working, reconnect the spark plug lead.

What to do if your engine does not produce spark?

If the engine does not produce spark, other areas of the ignition system should be checked before focusing on the ignition module as source of failure (see above). If no fault is discovered, the ignition module itself may need to be examined. To best determine the cause of failure, please consult an Authorized Dealer.