How do you screed sand?

- Set up screed guides. Once you have compacted the base, set up screed guides.

- Add the bedding sand. Once your screed guides are in place, add one inch of bedding sand on top of the compacted base.

- Screed the sand.

- Remove the screed guides.

How do you calculate sand and cement for screed?

The ratio of cement and sand in this case is 1: 4.

- The total volume of the mixture: 10 * 10 * 0.05 = 5 cu. m

- The amount of water will be approximately equal to half of the total volume, so 5-2.5 = 2.5 cubic meters will be required. m dry mix.

- Based on the ratio of 1: 4, the cement will need 0.5 cu. ...

- Cube m cement weighs about 1300 kg, cubic meters. ...

- So, for 1 square. ...

- In bags, usually 50 kg. ...

How to make a DIY homemade screed from a rake?

To make a homemade screed:

- Cut a straight 1×4 board 2’ to 3’ long.

- Position a garden rake on the middle of the board.

- Drill holes in the board, and attach a piece of steel pipe strap to the board using bolts and wing nuts.

- Insert the rake under the metal strap and tighten up the nuts.

How to start a sand?

How to Start a Sand & Gravel Business. Sand and gravel enterprises operate in one of two main ways; they either limit the scope of their business to the storage and delivery of sand, rock and gravel, or they take part in the actual quarrying and manufacture of the raw material. The success of both types of sand and gravel companies depends on the local demand for sand and aggregate materials and the amount of competition in the area.

How to pour concrete on sand?

Part 2 of 2: Pouring

- Mix your concrete. Concrete is mixed by adding together Portland cement, sand, and coarse aggregate (gravel) together in a ratio of 1:2:4.

- Pour the concrete into the mold. You can sometimes get a truck to pour concrete straight into your form; otherwise, load it into wheelbarrows and tilt them into the ...

- Screed the top of the concrete. ...

What does it mean to screed sand?

A mixture of sharp and fine washed sands, screeding sand is ideal for floor screeding, plastering and rendering. Also ideal for laying blocks, paviors and patio slabs on.

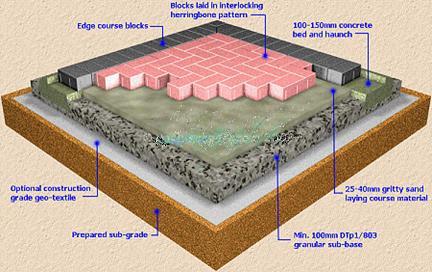

Do you compact sand before screeding?

Prior to adding your sand layer and screeding, you will need to prepare the base, which will include any necessary excavation, grading, compacting the sub-base, adding the base, and compacting the base. Once you have accomplished this, it is time to add your bedding sand.

How do you screed slabs?

4:4011:50How To Lay A Porcelain Paving Patio On A Cement Screed - YouTubeYouTubeStart of suggested clipEnd of suggested clipSo we're compacting the screed mix this is the way to do it i i believe and uh but there's nothingMoreSo we're compacting the screed mix this is the way to do it i i believe and uh but there's nothing wrong with trying different things. Well there's the first two in the 800 by 800 on a screen mix.

How do you flatten sand?

How to Flatten Lawn SandSpread lawn sand over your lawn or bare ground.Smooth the sand with the back portion of a garden rake so it slopes down one-half to 1 foot for each 50 feet of length. ... Fill the drum portion of a lawn roller half to entirely full of water, and seal.More items...

How do you compact sand without a compactor?

A lawn roller or hand tamper can be used to compact the moist soil, or you can walk over it.

How do you screed a floor?

How to Screed a Floor, Step by StepDivide up Your Floor Area. To begin the process of screeding your floor, you will need to divide it into sections. ... Apply a Layer of Screed. ... Levelling a Floor With Screed. ... Repeat the Process. ... Float Your Screed. ... Cure Your Screed. ... Let the Floor Dry.

What is the mix for floor screed?

Screed mix ratio can range between 1:3 – 1:5 cement to sand depending on the desired consistency and other factors. However, the traditional standard screed mix ratio is 1:4 cement to sand, creating a soft, malleable texture that is easy to work with.

How do you lay leveling sand?

1:462:36Prepare a Paver Base - How To - Menards - YouTubeYouTubeStart of suggested clipEnd of suggested clipUse one inch conduit pipe or similar material spread sand between the pipes known as screed rails.MoreUse one inch conduit pipe or similar material spread sand between the pipes known as screed rails. Take a 2x4 board. And drag it across the rails spreading. And smoothing the sand as you go fill.

Can you screed over slabs?

Screed us commonly applied on top of concrete slabs, adding a finishing later to commercial and residential flooring. Screed flooring is typically used to top the concrete slabs so that carpet, tiles, wood flooring or resin top coatings can be applied.

How do you compact fine sand?

2:4520:19THIS WILL RATTLE YOUR BRAINS OUT (Compacting Sand Under Slab)YouTubeStart of suggested clipEnd of suggested clipThis is a jumping jack and it is a compactor that can compact anywhere from 6 to 12 inches ofMoreThis is a jumping jack and it is a compactor that can compact anywhere from 6 to 12 inches of material. So if you need to add more than about three inches of material to get to the level you need you'

How do you compact sand for a concrete slab?

Use of a plate compactor works the sand into the spaces between the gravel. Compacting of dirt or gravel is done in 8" layers or lifts. Fill 8", compact and fill another 8". I did mine with 4" of 3/4" washed stone over undisturbed dirt and used a plate compactor.

What kind of sand do you use for paving?

The best sand to use between pavers is crushed rock or coarse, washed river sand. Pour the sand over the paved area and sweep it into every space between the pavers. Take the time to do a thorough job for long-lasting results.

Making your own screed: what are the right proportions?

If you want to install a new floor, you first need a solid surface. That is why a screed is placed between the filling layer and the floor finish. If you want to make screed yourself, you need to find out the correct composition of screed and have the exact proportions at hand. Find out everything you need to know to make your own screed.

Why install a screed?

To be able to place a finishing layer (tiles, parquet, etc.) on your floor, it must be evenly smooth. This is possible with a screed. A screed provides a strong foundation for your floor, protects utility pipes and contributes to a long life for your floor. Screed is mandatory, but also just a good idea.

Types of screed and their composition

Screed usually consists of sand, cement and water. Before you enthusiastically drive to the hardware store, you should know that there are different types of screed. So other combinations are possible.

The composition of traditional screed (sand cement screed)

This time we are talking about the public's favourite among screeds: sand-cement screed. This cement-based screed can be used as a flat surface for all types of floor coverings such as tiles, laminate, parquet, etc.

Making screed: which cement to choose?

If you want to make sand cement screed, you can choose from different types of cement. Your chosen cement also determines the ultimate strength of the screed. Commonly used types of cement are Portland cement (CEM I) and Portland composite cement (CEM II). But blast furnace cement (CEM III) and composite cement (CEM V) are also contenders.

What strength class should your cement have?

The most common cement strength classes are 32.5, 42.5 and 52.5. If the temperature of the substrate or of the ambient air is between 10° Celsius and 25° Celsius, you choose the strength class based on the drying time you want to achieve. For normal hardening, choose strength class 32.5, for faster hardening, strength class 42.5 is more suitable.

Which sand to use for screed?

A common mistake when making screed is using sand that is too fine. For the production of traditional screed (sand cement), you should preferably use coarse river sand with a grain size of 04/07. Due to the coarse, round grain thickness, this sand is very easy to work with and you obtain a stronger screed with less shrinkage stress.