How do you perform a crankshaft position relearn?

- Turn off all of the accessories.

- Accelerate the vehicle to 55 mph at part throttle.

- Cruise at 55 mph for another 5-6 minutes.

- Decelerate to 45 mph without using the brakes, and maintain 45 mph for 1 minute.

- Perform 4 deceleration cycles, without using the brakes, of 25 seconds each where no specific speed is necessary.

How to relearn a crankshaft position sensor?

This entire process of relearning the crankshaft position sensor is called the “CKP (Crankshaft Position) Variation Learn.” With the help of this process, you can reset the positional information in the memory of your car’s PCM memory and replace it with the information from the new crankshaft sensor. The steps are as follows:

What is a crankshaft relearn?

A crank relearn is a process that the PCM goes through to recalibrate its knowledge of the relationship between the crankshaft and camshaft. That’s necessary because the crank and cam are connected by a timing chain or timing belt.

How do you reset the crankshaft position?

The proper procedure for resyncing or relearning the crankshaft position is called the "CKP Variation Learn." The CKP Variation Learn procedure resets the positional information in the PCM's memory and replaces it with updated information from the new crankshaft sensor.

How do I use the crankshaft position variation learn procedure?

Select the crankshaft position variation learn procedure (CASE Learn)on your scanner. Make sure that the transmission is in Park. Start the engine. Apply the brakes and hold the pedal firmly.

Why is it necessary to have a timing belt on a crankshaft?

Can crank relearn fix P0300?

How do you manually relearn a crankshaft position sensor?

3:045:31P0335 Crankshaft Position Sensor Relearn procedure with cheap ...YouTubeStart of suggested clipEnd of suggested clipCut release the accelerator pedal. So it's just one quick throttle turn the ignition switch off I'mMoreCut release the accelerator pedal. So it's just one quick throttle turn the ignition switch off I'm gonna turn that off right now.

How do you relearn a crankshaft sensor without a scanner?

How do you relearn a camshaft sensor without a scanner?Turn off all of the accessories. ... Accelerate the vehicle to 55 mph at.Cruise at 55 mph for another 5-6.Decelerate to 45 mph without.Perform 4 deceleration cycles,Accelerate to 55 mph and cruise.Stop the vehicle and idle for 2.Oct 11, 2020

What happens if you don't relearn a crankshaft position sensor?

Failure to do such will result in over revving of the engine, causing possible engine damage. 8. Once the engine has returned to idle, check the status of Diagnostic trouble code P1336. If the scanner indicates that the CASE has been learned, the relearn procedure is now complete.Mar 19, 2016

How do you crank relearn?

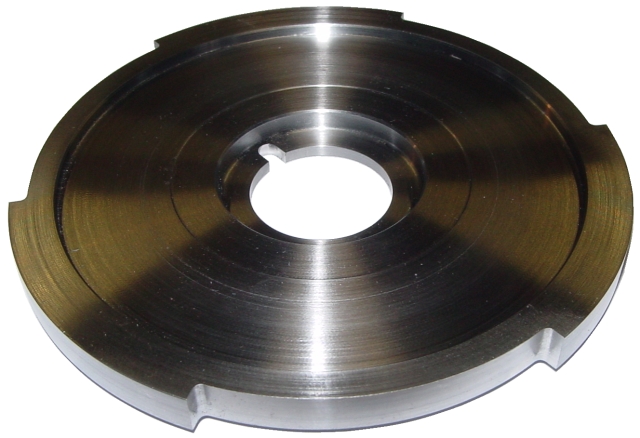

0:023:09How to do a Crank Sensor Relearn using HP Tuners - YouTubeYouTubeStart of suggested clipEnd of suggested clipRead is correct to the engine rotation when removing a flywheel or flex plate on the back of theseMoreRead is correct to the engine rotation when removing a flywheel or flex plate on the back of these engines the crank sensor reluctor ring is held in place by the assembly.

Will disconnecting battery reset crankshaft sensor?

To reset the check engine light you can disconnect the battery via the negative battery terminal and let the vehicle sit for an hour before reconnecting the battery. This will drain all of the power from the electronics and clear any short term memory.Dec 20, 2016

What is a relearn procedure?

The three types of relearn procedures are auto relearn, stationary (manual) and OBD. Some vehicles may use a combination of two or more relearn types. Indirect TPMS systems use an initialization procedure which may require a TPMS tool to figure out the steps involved to reset the system.Mar 23, 2018

How do you reprogram a crankshaft sensor?

0:051:00Crankshaft Position Sensor Replacement & Relearn | Snap-onYouTubeStart of suggested clipEnd of suggested clipBack on the scanner screen select crank pattern. Clear select continue once crank pattern clear isMoreBack on the scanner screen select crank pattern. Clear select continue once crank pattern clear is complete select crank pattern. Learning select continue the relearn is complete.

What scanner can do a crankshaft relearn?

The FOXWELL NT510 GM scanner will relearn the crankshaft position sensor on a 2009 chevy cobalt.

Do I have to relearn crankshaft position sensor?

Camshaft and crankshaft position sensor replacement is often necessary on many cars due to the common results of heat and vibration. However, if the proper relearn process is not performed to account for mechanical wear and manufacturing tolerances when replaced, you may face unnecessary comebacks and complaints.

How do you start a car with a bad crank sensor?

How to start a car with a bad crankshaft sensor: turn on the ignition if and only if you have the check engine light on and minimal symptoms beyond that. If your car misfired once or twice, or if you just started to notice uneven acceleration, it is drivable but time to take it to the shop.

What is a case relearn on a GM?

A CASE relearn is a Crank Angle Sensor Error relearn, which realigns the position between the crankshaft position sensor and the camshaft position sensor. This relationship helps the vehicle determine advanced misfires.Nov 3, 2011

How do you relearn a throttle body?

1:112:42When Should I Reprogram My Car's Throttle Body? - YouTubeYouTubeStart of suggested clipEnd of suggested clipYou might have to let it run for three minutes and then shut the vehicle off. And then run it againMoreYou might have to let it run for three minutes and then shut the vehicle off. And then run it again for three minutes. It depends on the type of vehicle.

Crank relearn instructions with and without a scan tool

To perform the relearn, proceed as follows: Connect a scan tool to make sure there are no trouble codes stored in the computer’s memory. If there is any power train trouble code other than P1336 (Crankshaft Position Variation not learned), the computer will disable the relearn function until the problem that caused the code has been eliminated.

Crank Position Relearn - 2000-2014 Silverado & Sierra HD - GM-Trucks.com

Hello all, quick question: A while back I was loking into getting a custom PCM tune for my 07' classic 2500HD 6.0. After some research I was discovered I would need a "crank position sensor relearn" done after installing the new pcm or else the truck would start throwing codes. I searched around ...

Crank Relearn Instructions (With and Without an OBD Scanner/Reader ...

These Crank Relearn Instructions may not apply to all vehicles. But they're close to how it's done on most cars. To perform the relearn, proceed as follows:

Crankshaft position sensor relearn without scanner

Replaced CKP sensor now need to do the relearn do not have access to scanner and mechanic could not get it until next week. Reply 1: Hello, ...

How do i reset the computer after i change the crank shaf...

My vehicle is idoling really high when i am just sitting and if i pull up to a light it acts like it wants to turn off... When i first start car in morning i let it warm up the electronis throtle light comes on blinking i then turn car off and back on and it goes away... the engine light stays on though

Why is it necessary to have a timing belt on a crankshaft?

That’s necessary because the crank and cam are connected by a timing chain or timing belt. Over time, the timing chain/belt can stretch and that stretch changes the relationship and timing between the crankshaft and camshaft.

Can crank relearn fix P0300?

That difference can cause misfires like P0300 or specific cylinder misfires. Performing a crank relearn doesn’t fix the timing chain/belt stretch, but it does allow the PCM to learn about the stretch that’s occurred since the car was manufactured and adjust its valve timing commands.

Why is it important to release throttle when engine RPM starts to decrease?

That’s the variation learn fuel cutoff RPM (depending upon the engine), and that it’s important to release the throttle when the engine RPM starts to decrease as a result of the fuel cutoff going into effect. Failure to do such will result in over-revving of the engine, causing possible engine damage.

What temperature should the coolant be on a car?

Make sure that the hood is closed. Start the engine and make sure that the engine coolant temperature is at least 158 degrees F. (70 degrees C.)

Can You Reset A Crankshaft Position Sensor?

Yes, but there’s a catch. This magnetic sensor reads the pickup from the crank in each of its rotations. Your car computer takes this data in and compares it simultaneously with the database information to ensure that they both are in sync.

Does Resetting The Crankshaft Position Sensor Solve No Start Problem?

Yes. If your car shuts down intermittently without any warning and stalling has become a part of your commute, this no-start issue can be resolved by resetting the sensor.

When Should You Reset A Crankshaft Position Sensor?

If you have successfully replaced your crankshaft position sensor but are still seeing the no start issue, then it is time to reset it. In fact, you should reset the crankshaft position after the replacement, whether you are getting trouble codes or not.

How To Reset Crankshaft Position Sensor

Many have the question that if your engine is running after the replacement of the crankshaft position sensor without any problem, what is the need to go through the relearning/resetting steps?

How Long Does It Take To Reset?

If you use the method that includes the usage of a scanner, the scanning process itself will take 10 minutes. Other than that, the entire process can be finished within 30 minutes to an hour, depending on your professionalism and ability to conduct the steps.

Final Words

So you have finally learned and resolved how to reset the crankshaft position sensor no start issue! As you saw, it can be easily resolved with a scanner, where you can perform the CKP Variation Learn or you can resolve it without a scanner, which involves resetting it through acceleration and deceleration cycles, with the transmission in your favor as you need it..

What is a crankshaft sensor?

The crankshaft sensor on GMC vehicles is synced to the powertrain control module, or PCM. When the crank sensor is replaced, it must be resynced to the PCM. Without resyncing, the PCM cannot properly determine the position of the crankshaft.

How to learn CKP?

Power on the scan tool and select "PCM" from the main welcome menu. Select "Special Functions" from the secondary screen, then choose "CKP Variation Learn" from the "Special Functions" menu .

Why is it necessary to have a timing belt on a crankshaft?

That’s necessary because the crank and cam are connected by a timing chain or timing belt. Over time, the timing chain/belt can stretch and that stretch changes the relationship and timing between the crankshaft and camshaft.

Can crank relearn fix P0300?

That difference can cause misfires like P0300 or specific cylinder misfires. Performing a crank relearn doesn’t fix the timing chain/belt stretch, but it does allow the PCM to learn about the stretch that’s occurred since the car was manufactured and adjust its valve timing commands.