How do you measure socket size?

- Insert the shank of the bolt into the holes in a bolt-sizing gauge.

- Locate the printed bolt size to the side of the correct hole on the gauge (for example, 1/2, 3/4 or in mm for metric bolts).

- Locate the socket head in the socket set that has this size printed on its side.

- Turn on the digital caliper and set it to read in inches, not millimeters. ...

- Close the caliper jaws until each jaw rests on one flat side of the nut on opposite sides.

- Check the caliper display. ...

- Turn on the digital caliper and set it to read in millimeters, not inches.

What size socket do I Need?

- Shallow length sockets: These are helpful for tight spaces that can be tough to operate in.

- Standard length sockets (intermediate): These are best for most basic projects that you’ll take on.

- Deep sockets: A deep socket can help you reach bolts that are far down in a vehicle or piece of machinery that you’re working on.

What are the most common sizes of sockets?

⅜-inch drive size sockets are the most common and most available. ¼-inch drive size sockets are ideal when you are in tight spaces or when you are working with recessed nuts. What is the most common socket? 10mm sockets and 36mm sockets are typically the most commonly used sizes.

What are the socket sizes in order?

Standard Socket Sizes

- 1/4 inch drive (0.6 centimeters)- Works with 4mm to ( 4.5 mm, 5mm, 5.5 mm, 6 mm, 7 mm, 8 mm, 9 mm, 10 mm, 11 mm, 12 mm, 13 ...

- 3/8 inch drive (0.9 centimeters) – Works with 5.5 mm to 22 mm sockets.

- 1/2 inch drive (1.3 centimeters): Works with 8 mm to 30 mm sockets.

- 3/4 inch drive (1.9 centimeters)- Works with 36 mm to 80 mm sockets.

What size socket or wrench is needed?

You at least need a set of 3/8″ (drive size) sockets set with sizes 8-19mm. Some vehicles use Allen or Torx bits for the caliper guide pins. Torx and Allen bits are not interchangeable. The wrong bit may feel like it fits, but it might damage the female head of the bolt.

What does L mean on an Allen wrench?

How to measure socket size?

How do I know my socket size?

How do you measure socket size?Insert the shank of the bolt into the holes in a bolt-sizing gauge.Locate the printed bolt size to the side of the correct hole on the gauge (for example, 1/2, 3/4 or in mm for metric bolts).Locate the socket head in the socket set that has this size printed on its side.Jun 20, 2020

What are the socket measurements?

There are four common socket sizes: 1/4 inch (0.6 centimeters), 3/8 inch (0.9 centimeters), 1/2 inch (1.3 centimeters) and 3/4 inch (1.9 centimeters).Jul 25, 2011

How do you measure a socket wrench?

The size of the socket head is usually measured in two systems, the first is imperial (inches), and the other is metric (millimeters). The drive socket size is always calculated according to imperial measurements as it is considered international standards from these two sizes.

What is the outside diameter of a 3/4 socket?

Impact 3/8" Drive Deep Well Sockets Features:Item #DiameterTip Outside Diameter18774793/4"1-1/16" / 27mm188233213/16"1-3/16" / 30mm18774807/8"1-3/16" / 30mm188233315/16"1-1/4" / 32mm21 more rows

How are 12 sockets measured?

In the current market, socket sizes are divided into two systems: SAE (imperial, measured in inches) and metric (measured in millimeters). Both 6-point and 12-point sockets are measured using these two systems. The popular range is 5.5~24mm.Aug 1, 2014

What is the most common socket size?

⅜-inch drive size sockets are the most common and most available.Dec 20, 2021

How do you measure bolt socket size?

TipInsert the shank of the bolt into the holes in a bolt-sizing gauge. ... Locate the printed bolt size to the side of the correct hole on the gauge (for example, 1/2, 3/4 or in mm for metric bolts).Locate the socket head in the socket set that has this size printed on its side.Jul 17, 2017

What size is a 3/4 socket in mm?

Metric / Standard Wrench Conversion ChartBolt DiameterMetricStandard1/2"19mm3/4"9/16"21mm13/16"22mm7/8"5/8"24mm15/16"39 more rows•Apr 9, 2020

What is socket size drive?

The drive socket size is a measurement of the distance between the flat sides of the square recess. The drive socket size must match the drive square size of your turning tool for the socket to fit correctly. For example, a 1/4″ drive or 1/4″ square drive will attach to a turning tool that has a 1/4″ drive square.

What order do standard sockets go in?

Six Point Standard Sockets (3/8, 7/16, 1/2, 9/16, 5/8, 11/16, 3/4, 13/16, 7/8, 15/16, 1)

How big is a 32mm socket?

Standard / Metric Wrench Conversion ChartBolt DiameterStandardMetric1"25mm3/4"1-1/8"29mm1-1/4"32mm7/8"1-5/16"34mm39 more rows•Aug 26, 2019

What is the standard size of a 32 mm socket?

3/4" Drive 32mm 12-Point Metric Standard Length Hand SocketWeight0.8 lbsNut End Outside Diameter (B)45.4Socket Length (L)56.4Socket Size32Socket Type12 POINT5 more rows

Nut & Bolt Size Conversion Chart - Abbots Tools.co.uk

About Abbots Tools. Abbots Tools is a subsidiary of Midland VW Ltd and is registered in the UK for VAT, number: 784 5441 03. All orders shipped to UK & EU addresses will be charged VAT at 20% unless the address is in the EU but outside of the UK and a relevant EU VAT number is supplied in your account.

How to Measure Socket Drive Size

The size of the socket head is usually measured in two systems, the first is imperial (inches), and the other is metric (millimeters). The drive socket size is always calculated according to imperial measurements as it is considered international standards from these two sizes.

How to Measure a Nut for a Socket Size

In this section, we will show you how to measure drive socket size in both imperial and metric systems, but in this case, you will need a digital caliper to determine the socket size quickly. After taking the digital caliper, follow the next steps.

What Is The Standard Socket Wrench Size?

You can see three types of common socket sizes in the market, they are:

Final Verdict

Hopefully, you have got the idea with many more bonus topics related to this article, including how to measure socket drive size. It will help you a lot in doing some advanced-level work. If you have any questions related to this topic, you can inform us in the comments section below.

What does L mean on an Allen wrench?

L indicates the overall socket length. What are Allen sizes? Allen wrenches are made in fractional inch and metric sizes. Probably the three most common sizes are 5/32-inch, 3/16-inch and 1/4-inch—in metric, 4-, 5-, and 6-mm see a lot of action.

How to measure socket size?

How do you measure socket size? Place the end of a measuring tape on one of the flat sides of the nut's outer perimeter. Stretch the tape measure across the nut's diameter to the flat-side directly across from the one your pulling from.

The Systems to Measure Socket Drive Size

We can measure the socket drive size in two systems. The first one is the Imperial system which is measured by inches and the second one is the Metric system which is measured by millimeters. However, the drive socket size is always calculated using an imperial measurement system. The imperial system maintains an international standard level.

How to Measure Socket Drive Size

We have discussed the systems of how to measure socket drive size and now we are going to elaborate on how to measure a nut for a socket size step by step. If you are quite eager to know about “how do I know what size socket I need”, you need to read the whole paras.

Final Words

We hope that the answer is now clear on how to measure socket drive size. We have tried to cover everything you need to know about how to measure socket drive size. Supporting questions are also mentioned there.

How to Measure Socket Drive Size

In the diagram above, the three key dimensions of a socket are labeled as Drive Hole, L, and S. These key dimensions determine the usage of this socket as follows:

Socket Sizes:SAE (INCH, fraction) & Metric (mm)

In the current market, socket sizes are divided into two systems: SAE (imperial, measured in inches) and metric (measured in millimeters). Both 6-point and 12-point sockets are measured using these two systems. The popular range is 5.5~24mm. SAE is used primarily in the United States and metric is used primarily in Europe and Asia.

Socket length

Sockets are available in deep, semi-deep and standard sizes. You can select the length most suitable for your working environment. The semi-deep size is designed specifically for 3/8" DR.

Why Do You Need Socket Sets?

Sockets are generally used to tighten or loosen different fasteners. They can be an alternative to the conventional wrench if you know their usage. Most DIY enthusiasts and mechanics prefer having a set handy.

Types of Socket Drives

The drive is the main part of the socket. It is the hole where the socket is attached to a turning tool. Like a wrench or a ratchet. The type of drive depends on the task at hand.

Types of Sockets

Now that we’ve discussed the types of socket drives, let’s discuss the types of sockets. There are two common types of sockets available. The use of sockets has changed a lot over the years.

Metric Socket Size Chart

The most common size chart for sockets is the metric size. They’re used all over the world minus a few exceptions. If you’re in a part of the world where the metric system is followed, this is the right chart for you.

FAQs

Answer: If you have a socket set, your socket size will likely be written there. Otherwise, you will have to measure it with tape.

Final Word

Now you know the socket size chart. Sockets are a versatile tool. They’re very easy to use and they can improve your experience drastically. The key to a good experience with sockets is knowing which one to use.

Imperial Measurement System

The imperial measurement system is mostly used in the UK. It is also used in other Commonwealth countries. Units like inches and feet are used here rather than millimeters, centimeters, or meters. Let’s get to know the steps of measuring nuts in imperial units.

Metric System

The metric system is the globally accepted measurement system now. This measurement system is used for many common home repairs.

Measuring Nut Threads

While measuring nuts, identifying and counting threads of nuts is also important. Because there are a lot of threaded fittings. We’ve talked about this in two steps. The steps are as follows.

Step 1

Turn on the digital caliper and set it to read in inches, not millimeters. Set the nut on a flat surface. Open the caliper jaws far enough to allow the nut to fit between them.

Step 2

Close the caliper jaws until each jaw rests on one flat side of the nut on opposite sides.

Step 3

Check the caliper display. The reading shows the size of the nut as a decimal. Imperial sockets are sized in fractions of an inch. The website Ham Universe has a table for converting decimals to fractions. Look through the table's decimal column and select the first decimal larger than your caliper reading. Select the corresponding fraction.

Step 1

Turn on the digital caliper and set it to read in millimeters, not inches. Set the nut on a flat surface. Open the caliper jaws far enough to allow the nut to fit between them.

Step 2

Close the caliper jaws until each jaw rests on one flat side of the nut.

Step 3

Check the caliper display. The reading shown is the size of the nut as a decimal. Metric sockets are sized in millimeters. The website Sizes has a table showing metric socket sizes. Select the first millimeter size larger than your caliper reading. This is the size of your nut and required socket.

What is the difference between a 12 point socket and a 6 point socket?

You can slip it over the hardware in any one of 12 positions, which makes it easier to align. While 12-point sockets are well suited for most light and household tasks, six-point sockets, on the other hand, have been chosen for more significant hardware situations that require substantial torque.

What are some examples of impact sockets?

Impact sockets are made in such a way they work with these other tools. A prime example is an electric or pneumatic impact wrench. If you use these, you will need a socket sets built to withstand these higher torques.

Can you use a wrench in a shed?

Using a wrench can be accessible when you need to tackle jobs in your shed or around the home. However, when you have many varying sizes to work on, you can quickly overload your portable workbench.

Can you touch a nut in a shallow socket?

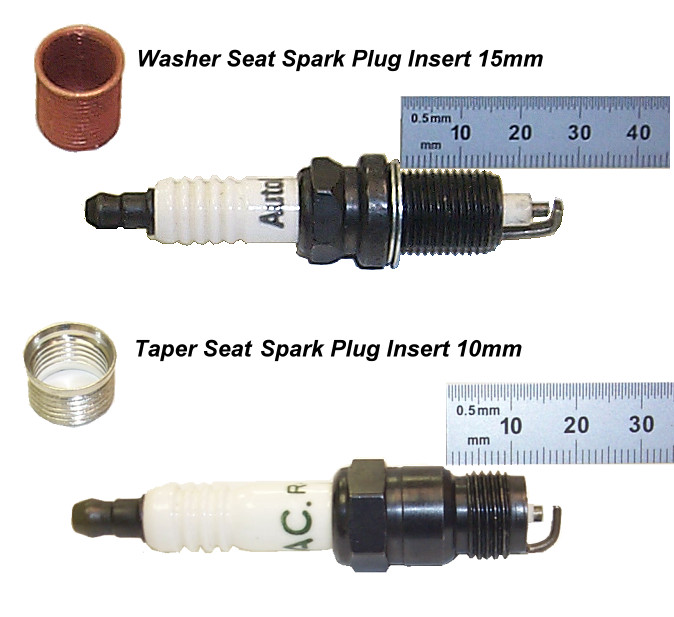

Conventional shallow sockets may not touch a nut or bolt before the top of the stud or bolt hits the top of the socket, or you are working in a confined space. Spark plug sockets are a good example, as are some wheel nuts.

What does L mean on an Allen wrench?

L indicates the overall socket length. What are Allen sizes? Allen wrenches are made in fractional inch and metric sizes. Probably the three most common sizes are 5/32-inch, 3/16-inch and 1/4-inch—in metric, 4-, 5-, and 6-mm see a lot of action.

How to measure socket size?

How do you measure socket size? Place the end of a measuring tape on one of the flat sides of the nut's outer perimeter. Stretch the tape measure across the nut's diameter to the flat-side directly across from the one your pulling from.