How do you adjust a hydraulic pressure relief valve?

- Refer to the machine drawings to determine which circuit requires adjustment.

- Locate and remove the hydraulic hose or hoses on the system side of the relief valve.

- Connect a 5,000 psi pressure gauge between the relief valve and the pump.

- Loosen the pressure relief valve adjustment all the way out.

How to set a hydraulic relief valve?

How to Set a Hydraulic Relief Valve. Refer to the machine drawings to determine which circuit requires adjustment. Locate and remove the hydraulic hose or hoses on the system side of the relief valve. Connect a 5,000 psi pressure gauge between the relief valve and the pump. Loosen the pressure relief valve adjustment all the way out.

How do you adjust a pressure relief valve?

How to Set a Hydraulic Relief Valve

- Refer to the machine drawings to determine which circuit requires adjustment. Locate the relief valve for the circuit.

- Locate and remove the hydraulic hose or hoses on the system side of the relief valve. ...

- Connect a 5,000 psi pressure gauge between the relief valve and the pump. ...

- Loosen the pressure relief valve adjustment all the way out. ...

How to set hydraulic pressure?

Skill Level

- Remove the caps from the adjustment ports.

- Loosen the Jam nuts.

- You will have a small amount of leaking Hydraulic oil when the caps are off.

- Dial the Differential all the way clockwise. ...

- Now Dial the Compensator all the way out counter clockwise. ...

- Now place the pump in Cooling Mode to start the Hydraulic pump.

How to adjust a hydraulic pump output pressure?

- Start the engine on your log splitter as you normally would.

- Set the pump lever in the neutral position.

- Twist the screw on the side of the pump clockwise with a flat blade screwdriver to increase pressure, according to the scale printed or embossed on the side.

How do I adjust my adjustable pressure relief valve?

0:311:26Adjusting Pressure Relief Valve Pressure - YouTubeYouTubeStart of suggested clipEnd of suggested clipAnd then righty-tighty increases lefty loosy decreases. And then while you hold on this the lockMoreAnd then righty-tighty increases lefty loosy decreases. And then while you hold on this the lock hold this setting in place and then lock it with a lot nut. And you'll be all set.

Can a pressure relief valve be adjusted?

Most valves have a locking nut. Once you unscrew this nut, you will be able to turn the adjustment screw, knob, or bolt. Adjust it until the pressure shown on your gauge reaches the desired level.

How do you adjust pressure relief?

0:041:21How To Adjust A Pressure Relief Valve - YouTubeYouTubeStart of suggested clipEnd of suggested clipAll you need to do is just take that Allen wrench. Slide it into the the key that's on the bottom ofMoreAll you need to do is just take that Allen wrench. Slide it into the the key that's on the bottom of the pressure relief valve. And turn this Center plug. The way it's calibrated.

How do you adjust a hydraulic pressure regulator?

0:001:47hydrolec adjusting the relief valve - YouTubeYouTubeStart of suggested clipEnd of suggested clipAnd as you screw your relief cartridge in you'll be able to see the gauge. Increase in pressure whenMoreAnd as you screw your relief cartridge in you'll be able to see the gauge. Increase in pressure when you get to the set pressure you need that's when you lock this nut up.

What should a pressure relief valve be set to?

The relief valve setting(s) should be at least 10% or 15-psig, whichever is greater, above the maximum operating pressure. Where unstable process conditions exist, this differential should be at least 10% above the maximum operating pressure or 25-psig, whichever is greater.

Why is water coming out of the pressure relief valve?

If the temperature's or pressure in your tank exceeds a certain level (often times 210 degrees and 150 psi), the relief valve opens up and allows some water to drain out of the tank. Cold water is then added to the tank in order to lower the temperature and pressure inside.

How do you adjust a Bell and Gossett pressure-reducing valve?

Adjust the reducing valve pressure setting by loosening the jam nut on top of the reducing valve and turning the slotted adjusting screw. Turn the screw clockwise to increase the set pressure, or counterclockwise to lower the set pressure.

How do you adjust a safety relief valve?

0:051:14NVE - How to set a presure relief valve - YouTubeYouTubeStart of suggested clipEnd of suggested clipTurn the spring tightener nut clockwise with that BTW millimeter wrench to increase the pressure.MoreTurn the spring tightener nut clockwise with that BTW millimeter wrench to increase the pressure. Use a liquid-filled gauge to verify pressure relief settings.

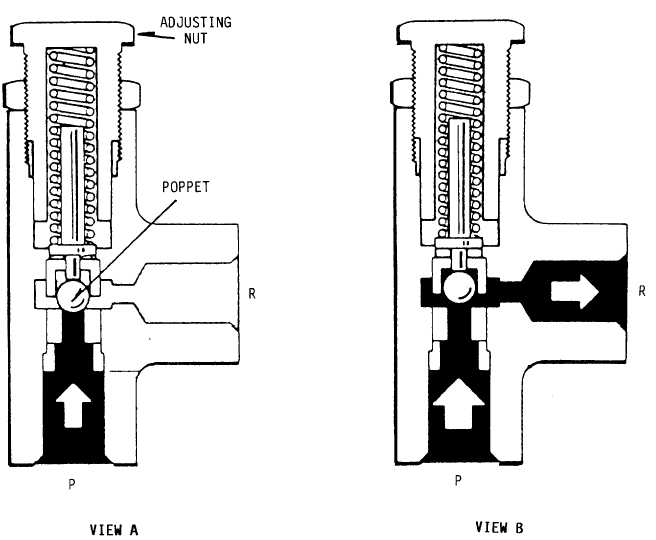

How do hydraulic relief valves work?

A relief valve works by providing an excessively pressurized fluid an open path to tank with the goal of reducing work port pressure. As fluid pressure begins to rise, force from that pressure is applied to the bottom of the spool or poppet, similar to what occurs to the piston of a cylinder.

What happens if hydraulic pressure is too high?

If the pressure is found to be too high, the system will use excessive input energy and the fluid may overheat. In addition, excessive pressure may stress components and create a very real danger to humans.

How does a hydraulic relief valve work?

Although they have a number of variations, all valves work by balancing the hydraulic force with an adjustable spring force. Heat is created whenever the relief valve opens in response ...

What does excessive heat mean on a relief valve?

Excessive heat can be an indicator that a relief valve is malfunctioning or improperly adjusted. Look for signs of burnt paint or melted plastic on or near hydraulic components.

Can hydraulic hoses be life threatening?

This injury often appears to be minor; however, it can quickly become life-threatening.

Can you cap off a relief valve?

Do not cap off the return or tank side of the relief valve. Capping off or plugging unused hoses and fittings prevents the loss of hydraulic fluid and the introduction of contaminates into the system. Using any other method of capping or plugging a hose other than with the proper JIC plug or cap is unsafe and should never be attempted.

How does a hydraulic relief valve work?

All hydraulic system relief valves work by balancing the hydraulic force with an adjustable spring force. Whenever the relief valve opens in response to a predetermined pressure, it releases heat. A properly adjusted valve will enable the system to operate correctly, while controlling the amount of heat generated.

What happens when a relief valve is set but is releasing pressure before a system reaches maximum pressure?

If a relief valve is set but is releasing pressure before a system reaches maximum pressure, or if it’s constantly leaking or chattering, something may be wrong with the system.

What is a safety relief valve?

Pressure relief valves and safety relief valves are what keep a facility safe. If your system builds up more than safe maximum pressure, safety relief valves open up to let off additional pressure, keeping your facility, your employees, and your equipment safe.

What function it performs in the target hydraulic system and what the system's basic operational parameters are (oil type and working temperature)

It gives me information about the expected pressure setting and alerts me if the requested value is in the right/safe ballpark or not.

The valve's construction (design)

This is very important because knowing the relief valve's type (e.g. direct-acting seated, balanced piston, balanced poppet, etc..) gives me the information about

Where the pressure gauge is placed during the adjustment procedure

This is something that gets overlooked often, especially in the field, where the choice of accessible measuring points is limited, but it can happen in a shop as well.