How do you adjust a 2 stage hydraulic pump?

- Start the engine on your log splitter as you normally would.

- Set the pump lever in the neutral position.

- Twist the screw on the side of the pump clockwise with a flat blade screwdriver to increase pressure, according to the scale printed or embossed on ...

Full Answer

How do I adjust the hydraulic pressure on my pump?

You can adjust the various working aspects of the pump, including pressure settings and accuracy of the valve, by making minor adjustments with common household tools. Adjust the hydraulic gauge by locating the adjustment screw on the back of the gauge.

How do you adjust a 2 stage hydraulic pressure switch?

Adjust the pressure switch, located behind the hydraulic gauge, by using a wrench to loosen the lock-nut on the switch, then turning the adjusting screw. Click to see full answer. Similarly, it is asked, how does a 2 stage hydraulic pump work? Two-stage pumps are typically mounted to small gas or diesel engines.

What is a two stage hydraulic pump?

Two stage pumps, often called log splitter pumps, are a great way to get better performance without increasing horsepower. A two-stage hydraulic pump is two gear pumps that combine flow at low pressures and only use one pump at high pressures.

How do you adjust the needle on a hydraulic gauge?

Adjust the hydraulic gauge by locating the adjustment screw on the back of the gauge. Use a flathead screwdriver to turn the screw. Turning the screw allows you to adjust the screw needle, turning it to zero when needed.

How do you adjust a 2 stage pump?

How to Adjust a 2-Stage PumpAdjust the hydraulic gauge by locating the adjustment screw on the back of the gauge. Use a flathead screwdriver to turn the screw. ... Adjust the pressure switch, located behind the hydraulic gauge, by using a wrench to loosen the lock-nut on the switch, then turning the adjusting screw.

How do I adjust the pressure on my hydraulic pump?

6:268:33Pressure Compensated Pump Adjustments - Part 1 - YouTubeYouTubeStart of suggested clipEnd of suggested clipWith a pressure gauge available on the pump outlet line. Simply turn the adjustment screw toMoreWith a pressure gauge available on the pump outlet line. Simply turn the adjustment screw to compress the spring until the desired maximum. System pressure is reached.

How do you adjust a hydraulic pump on a log splitter?

Twist the screw on the side of the pump clockwise with a flat blade screwdriver to increase pressure, according to the scale printed or embossed on the side. Turning the screw counterclockwise decreases pump pressure. Raise the guards on the sides and back of the splitter to the upright locked position.

How does a 2 stage pump work?

With a two-stage pump, a transfer valve is located at the outlet of the first-stage volute. It directs the water either to pump discharge VOLUME (parallel) position, or to second-stage intake PRESSURE (series) position, depending on the pump performance desired.

How do you adjust hydraulic flow?

0:328:48Flow Control Valves in Hydraulics - Full lecture with animation - YouTubeYouTubeStart of suggested clipEnd of suggested clipLater. The function of a flow valve is to reduce the rate of flow in its leg of the circuit flowMoreLater. The function of a flow valve is to reduce the rate of flow in its leg of the circuit flow reduction results in speed reduction at the actuator for an example of an actuator.

How do you adjust the flow rate of a pump?

For every pressure, the pump will only deliver one specific flow rate. Therefore, to control the flow of a centrifugal pump, simply set the output pressure to the point on the P-V diagram that allows the pump to deliver the desired flow rate. The output pressure of the pump is set using a back pressure regulator.

How does a 2 stage hydraulic hand pump work?

0:2413:13HOW A LOG SPLITTER PUMP WORKS - 2 STAGE GEAR PUMPYouTubeStart of suggested clipEnd of suggested clipThan then some gear pumps found on hydraulic systems because it is a two-stage gear pump it's gotMoreThan then some gear pumps found on hydraulic systems because it is a two-stage gear pump it's got two different sets of gears. Doing the pumping inside there in a common housing when it's assembled.

How do you adjust the speed on a hydraulic cylinder?

By adjusting the resistance, or opening, of this valve, you can modify the rate of oil flow to a cylinder and, therefore, the speed of its piston rod. Since the Flow Control Valve increases the circuit resistance, the pump must apply a higher pressure to overcome this resistance.

How can I make my log splitter more powerful?

1:097:17Log splitter Upgrades - YouTubeYouTubeStart of suggested clipEnd of suggested clipSo what you do is you take your drain plug off for your oil you put this on and then whenever youMoreSo what you do is you take your drain plug off for your oil you put this on and then whenever you drain your oil you can use this. This is over here.

What does a 2 stage hydraulic pump mean?

Hydraulic pumps convert mechanical energy into fluid power energy. All hydraulic pumps are positive displacement which means the outlet flow is sealed from the inlet flow. A small amount of fluid is designed to leak internally to lubricate and cool the internal components of the pump.

What is the difference between a single stage and two stage pump?

0:205:13Single-Stage vs. Two-Stage Pumps - YouTubeYouTubeStart of suggested clipEnd of suggested clipThe single stage or one impeller pump in the two stage or two impeller pump. With a single stageMoreThe single stage or one impeller pump in the two stage or two impeller pump. With a single stage pump. Water enters the eye of the impeller goes through the impeller. And directly out the discharge

What is the primary reason for using a two stage oil pump?

The answer is that a two-stage pump satisfies the special need to pump fuel oil which has certain characteristics that defy efficient pumping by single stage pumps. Fuel oil starts to break up, or "boil" at vacuum levels as low as 10 inches of mercury.

What is a two stage pump?

A two-stage hydraulic pump is two gear pumps that combine flow at low pressures and only use one pump at high pressures. This allows for high flow rates at low pressures or high pressures at low flow rates.

What is a gear pump?

Gear Pumps. A pump is simply a device that takes oil, usually from a reservoir, and moves it to somewhere else. Take note that a pump’s job is to move oil, not to create pressure. The pressure is a byproduct created outside the pump caused by resistance to fluid flow.

What does torque limiting do on a pump?

Torque limiting monitors the torque on the pump shaft and will minimize the displacement of the pump.

What is the movable end of a piston?

The movable end is attached to a swashplate which pushes and pulls the pistons in and out of the cylinder. The pistons are all attached to the rotating shaft while the swashplate stays fixed. Oil from the inlet flows into the cylinders as the swashplate is extending the pistons.

Which pump gives the best performance?

The piston pump gives us the best performance, but is almost always using the maximum power available. This means more fuel consumption. The single stage gear pump gives us the best fuel consumption, but the worst performance. The two-stage gear pump gives great performance and is good on fuel consumption and price.

Is a gear pump reliable?

Gear pumps are inexpensive and reliable. You can get many gear pumps for the price of one piston pump. So now the focus is turned to having two or more gear pumps that can be turned on or off. In most cases, you want to turn the pump off when pressures get to certain thresholds. This is exactly what a two-stage pump is.

Can you have more than 2 stages?

Another thing to not lose sight of is that you can have more than two stages. Many times, two stages will work great, but there might be another intermediate stage that needs to be added. No problem. You can add as many pumps as you need and have the unloader set for each as needed.

How Does a 2 Stage Hydraulic Pump Work?

A 2 stage pump is often regarded as an excellent time-saver. This is because the pump is composed of two pumping parts, along with an inside pressure-sensing valve which works by cutting between the two. A section of the hydraulic pump creates the max gpm flow rate at a relatively low-pressure rate.

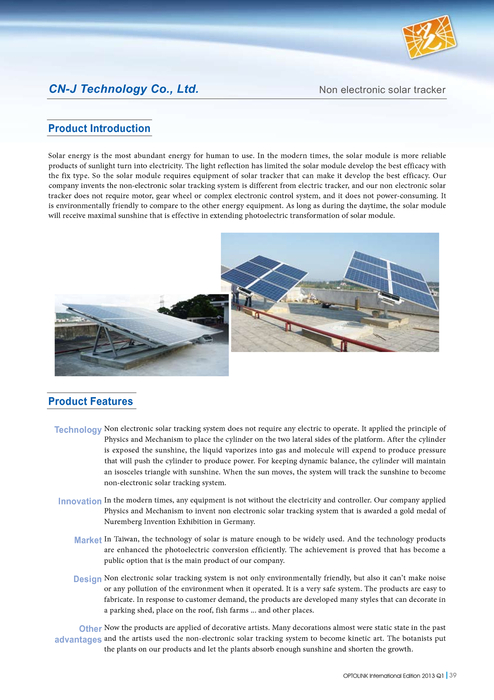

Working with a Hydraulic Log Splitter

In a standard log splitter, a log is placed by the operator on the splitter, shifting a directional valve so as to route fluid coming from the pump and into the cap end of the cylinder. Then, the smaller pump works by moving the piston rod at a low speed, and can still attain higher pressure in pushing the wedge to the log, splitting it.

How to Adjust a 2 Stage Hydraulic Pump?

2 stage hydraulic pumps are often seen in hydraulic systems. They work by allowing the passage of different substances right into the pump, as well as the other components that are in the system.

What is high pressure adjustment?

Whenever the system is moving a load, the high-pressure adjustment limits the system pressure. For instance, as a cylinder is extended, pressure in the system will build as necessary to move the load. Eventually, the cylinder reaches the end of its stroke, and flow is blocked.

What happens when a pressure compensating pump is stopped?

When the system is stopped completely, the pump stroke is reduced almost to zero. It will stroke only a very small amount or whatever is required to maintain the compensator setting in the line, overcoming any system bypassing or leaks. While a pressure-compensating pump is efficient, the standby pressure remains high.

How to make pressure settings?

To make the pressure settings, always adjust the load-sensing valve first. The pump should be deadheaded by closing the manual hand valve. With the pump-loading valve de-energized, pressure will build only to the current setting of the load-sensing valve. Adjust the load-sensing valve to the desired pressure.

What is a pressure compensating pump?

Pressure-compensating pumps are designed to deliver only the amount of flow required by the system to maximize efficiency and avoid heat generation. The compensator is adjusted to a pressure somewhat higher than that required to move the system’s heaviest load.

Why adjust load sensing valve?

The most common reason to adjust a load-sensing valve is because someone unfamiliar with the pump has mistakenly attempted to set the maximum system pressure by adjusting the load-sensing valve instead of the compensator. This not only can result in unstable system pressure but in some cases can also void any warranty on the pump.

Uses of a 2-Stage Hydraulic Pump

Standard 2-stage hydraulic pumps generate positive displacement – a static fluid volume at the outlet – each cycle. The primary benefit

How to Turn Off or Alternate the Pump

Alternating the 2-stage hydraulic pump between units is coordinated by the check and unloader valves.

Why Not Use a Piston Pump?

A piston pump operates according to variable displacement. Flow is determined by the angle of an internal slant disk attached to the pump shaft. Pump adjustments – like torque or horsepower limiters – allow piston pumps to emit a max flow rate regardless of pressure level.

The Panagon Systems Difference

Navigating around OEM assemblies and components – often outdated, out-of-service, or limited (and expensive) – can prove challenging. Panagon Systems has specialized in manufacturing industry-standard and custom hydraulic assemblies for 25 years. Reach out to our team for a consultation on your specific operational and equipment needs.