What happens if you put a diamond on the blade?

Metal in the diamond rim can get so hot that it actually covers the diamonds. Glazing over diamonds on the rim can cause blades to dull and stop cutting, even though there's a lot of life left on the diamond rim of the blade, Skaff continues.

What makes a good diamond saw blade?

One key factor is blade quality (diamond quality and concentration, and segment bond and width). Consider that two blades of the same diameter could have different diamond depths, amounts of diamond in the blade segment and segment heights. As with traditional diamonds, there are different grades assigned to synthetic diamonds for saw blades.

What should I do if my diamond blade is damaged?

Do inspect the diamond blade for damage that may have occurred during shipment or damage due to previous use. Do check mounting flanges for equal diameter, excess wear and flatness.

When should you not use a diamond saw blade?

Don’t use a new diamond saw blade or remount a used blade which has a core that is not flat or is cracked, which shows segment damage or loss, or which has a damaged arbor hole.

Will diamond blade cut metal?

Will Diamond Blades Cut Metal? Yes, certain diamond blades can cut through metal, but this will depend entirely on the blades application. Most diamond blades are used to cut through concrete, brick, tile, and asphalt.

What kind of blade is used to cut metal?

Ferrous blades are ideal for cutting metals that contain iron, such as stainless steel or cast iron. Choose a non-ferrous blade when cutting softer metals, like aluminum or copper. For the best results, use a diamond blade that's rated to cut the type of metal you are working with.

Can diamond be used to cut steel?

Diamond is great cutting tool material, but diamond tools (actually technically PCD tools) cannot cut ferrous metals like Steel or Cast Iron.

What is the best tool to cut metal?

Tin Snips. Like a pair of scissors, tin snips are an inexpensive handheld tool that cuts straight, or if the blade is curved, can cut curves and circles. Tin snips are ideal for cutting soft metals like aluminum and copper, and are especially useful for cutting sheet metal, gutters, metal roofing, and studs.

Can you use a diamond blade to cut aluminum?

Brass and aluminum are both relatively soft metals. So you don't have to go to the expense of a diamond blade to cut those materials. A good bi-metallic blade will work just fine. The blade material (or the cutting edge/teeth) just needs to be harder than the material you're trying to cut.

How do you cut a piece of metal?

9:4020:0113 Ways to Cut Metal - YouTubeYouTubeStart of suggested clipEnd of suggested clipAnd a little bit of time. But you can cut through anything with one of these and just take someMoreAnd a little bit of time. But you can cut through anything with one of these and just take some elbow. Grease. So the next step up from a hacksaw is a sawzall. And it's basically just a hacksaw with a

Can you use a masonry blade to cut metal?

We recommend using a diamond blade that's labeled as a ferrous-metal-cutting blade, but many tradespeople use a regular masonry diamond blade with good results.

Can I use a stone cutting disc on metal?

Stone cutting discs will actually cut metal but they will tend to tear up and fall apart as they chop their way through and due to this the flying debris can cause a great deal of harm and damage to yourself, others around you and also to any nearby objects.

Can I cut rebar with a diamond blade?

Rebar is the backbone of concrete construction and the bane of bits and blades alike. If cutting rebar when exposed, a diamond blade will make quick work of the cut, but it greatly reduces the life of the blade. This is because diamond blades “cut” by grinding the material as opposed to other blades that rip and tear.

What do diamond blades cut?

When most people imagine a power saw, they picture a metal blade with sharp teeth spinning at an incredible speed and slicing through a piece of lumber. But there are some saw blades that don’t use sharp teeth at all: diamond blades. These special blades spin around just like other saw blades, but they work quite differently.

Diamond blades: What do they cut?

The list of materials that diamond blades can cut through is too extensive to name every single item. We’ll provide plenty of examples, but we’d also like to give you a general idea based on the properties of diamond blades. What do we know about diamonds (besides being expensive)? It’s the hardest mineral known to man.

HOW DO DIAMOND BLADES WORK?

In the introduction, we said that diamond blades work differently from regular metal saw blades. Although we use the word “cut” loosely in most articles, the truth is that diamond blades don’t cut at all – they grind.

CAN YOU CUT TILE WITH A CIRCULAR SAW?

Yes, it’s possible to cut tile with circular saw, although if we are talking about a handheld circular saw, it is not necessarily advisable. A bench-mounted tile circular saw or masonry saw is the ideal tool for this type of job, but there are times when you can’t access one.

Nuts & Bolts – Typical Components of Diamond Blades

Typically synthetic rather than natural, diamond crystals allow manufacturers to control the shape and size. The synthetic process also allows for engineering crystals for specific applications. Cutting performance is determined by the type, shape, and size of these diamond crystals.

How Diamond Blades Work

Unlike most other blades, diamond blades don’t cut the material. Instead, they use friction created between the diamond-bonding matrix and the material being cut to work like a grinding wheel.

Types of Cuts with Diamond Blades

There are two primary methods of cutting with diamond blades, wet and dry cutting. As with all blades, one factor that severely affects the blade’s performance is heat – which can lead to segment loss, core warpage and cracking, and the need for a new blade.

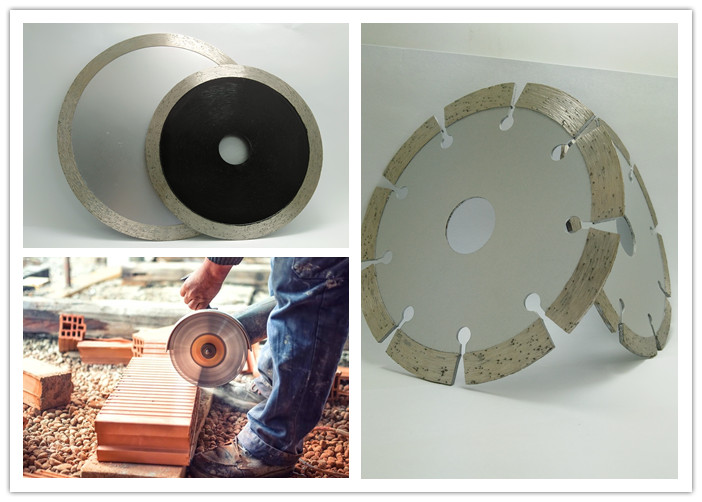

Segmented Diamond Blades vs Continuous Rim Blades

We added this section to the article after a reader posed the question of when to use segmented blades versus continuous rim blades. The answer is that it depends on a number of variables, including the material being cut, the speed of the cut, the finish quality, and the availability of water.

Using Diamond Blades with Steel

One additional consideration is when using diamond blades on concrete with steel in it. Rebar is the backbone of concrete construction and the bane of bits and blades alike. If cutting rebar when exposed, a diamond blade will make quick work of the cut, but it greatly reduces the life of the blade.

Diamond Blade Sizes, Tools and Costs

Diamond blades come in a variety of sizes from 4” for use with angle grinders and go up to 36”. Think about those walk-behind saws you see when crews are cutting up the roads or sidewalks – they’re using diamond blades.

Why does my diamond blade stop cutting?

Metal in the diamond rim can get so hot that it actually covers the diamonds. Glazing over diamonds on the rim can cause blades to dull and stop cutting, even though there's a lot of life left on the diamond rim of the blade, Skaff continues. This issue can be solved in the field by dressing the blade.

How does concrete cutting affect blade life?

How concrete cutting impacts blade life depends on the aggregate size, sand type (sharp and abrasive or round and non-abrasive), aggregate hardness (determined by rock type) and reinforcing steel (amount, grade and gauge). For example, a coarser aggregate with a lot of sand will wear a blade faster than concrete with less sand and less aggregate, ...

What are the factors that affect blade life?

Blade life can vary greatly depending on a number of variables. One key factor is blade quality (diamond quality and concentration, and segment bond and width). Consider that two blades of the same diameter could have different diamond depths, amounts of diamond in the blade segment and segment heights.

How does forcing a saw blade damage it?

Forcing the blade through material will damage the saw by increasing the amperage, burning up the motor and overheating the blade , which causes premature wear and damage, says Skaff. He has seen blades burned so badly they have a purple rainbow around the rim.

Why do we get fried blades back?

Fisher agrees, noting, "We get blades back all the time that are fried because water wasn't used. It doesn't take very long for the friction of concrete (or even asphalt) to burn up a blade.". Even dry blades can be used wet; doing so might actually increase production and blade life.

What is application specific blade?

While general-purpose blades can cover a variety of cutting tasks, application-specific blades are engineered with a specific bond to meet the needs of a certain application. They do the best job and will last longer, Skaff says.

Can diamonds be used to cut asphalt?

The harder material requires diamonds to be exposed more quickly, and a softer bond to hold the diamonds to the segment. "You could use a blade designed for concrete to cut asphalt and it will cut really fast, but it won't last very long," says Thom Fisher with Diamond Products.

What to consider when cutting metal?

An important thing to consider when you want to cut metal with your metal cutting circular saw is how secure the material is. If the material is not held firmly in place, it could result in severe accidents. To be on the safer side, these metal materials must be safe and secure.

What to consider when working with metal saw blades?

One thing you need to consider when working with metal saw blades is their depth setting. For your safety, you may want to consider how thick or thin the material you are cutting with is so that you do not use the wrong blade for it.

Is it safe to cut metal with a circular saw?

If you are cutting your metal with any other type of circular saw other than a circular saw blade for metal, it is risky. It may ruin not only the materials but also the saw. Many saws have a particular cutting speed, which they function best while cutting different materials.